A kind of preparation method of pumpkin pulp sauce shreds

A technology of pumpkin pulp and shredded sauce, applied in food preparation, bacteria used in food preparation, food science, etc., can solve the problems of resource waste, high cellulose content, discarding pumpkin pulp, etc., and achieve the effect of enhancing crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 200 kg of pumpkin pulp (pumpkin, peeled, pulp and seeds), cut the pumpkin pulp into strips with a length of about 15.0 cm, a width and a height of about 5.0 cm.

[0027] (2) Add 280kg of seasoning sauce to the cut pumpkin strips, and add 14.4L of seed liquid of Lactobacillus plantarum and Lactobacillus brevis respectively (the density of the strains is 2.5×10 8 CFU / mL and 2.7×10 8 CFU / mL), fermented in airtight at 27°C for 9 days.

[0028] A. The formula of the above sauce is as follows:

[0029] 100 parts of 8% salt water, 3.5 parts of cooking wine, 2.5 parts of white sugar, 0.1 parts of star anise, 0.2 parts of cumin, 0.05 parts of pepper, 0.09 parts of white pepper, 0.09 parts of black pepper, 4 parts of ginger, 1.2 parts of tangerine peel, and 2.1 parts of cinnamon.

[0030] According to the above formula, take water, add salt, heat to boil, add cooking wine, sugar and other spices, boil at 80°C for 40 minutes, cool and filter to obtain the sauce.

[00...

Embodiment 2

[0038] The steps of the method are the same as in Example 1, except that in "step (2)", 320 kg of seasoning sauce is taken, and 20.8 L of seed liquid of Lactobacillus plantarum and Lactobacillus brevis are added respectively (the strain density is 2.4×10 8 CFU / mL and 2.5×10 8 CFU / mL), and fermented in airtight at 22°C for 12 days. Compared with Example 1, the pumpkin pulp sauce silk ester fragrance prepared by this method is more prominent.

preparation example

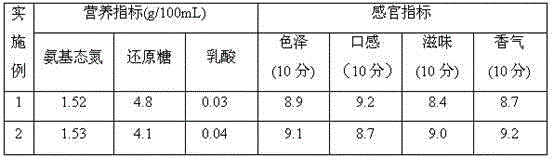

[0039] The preparation example of pumpkin pulp sauce shreds of the present invention, its quality analysis is as follows table:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com