Dispersions of nanoscale dental glass particles and methods for preparing the same

A dispersion and nano-scale technology, applied in dental preparations, dental prostheses, dentistry, etc., can solve the problems of huge difference in refractive index and poor transparency, and achieve high X-ray opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

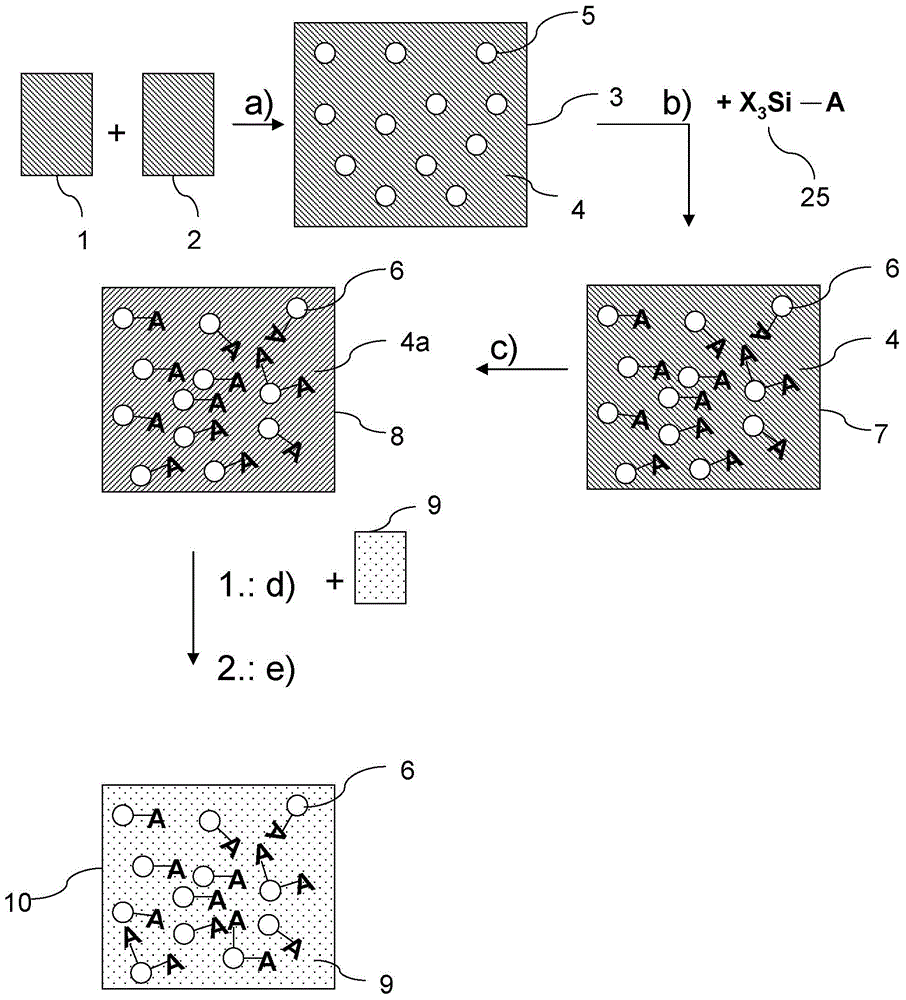

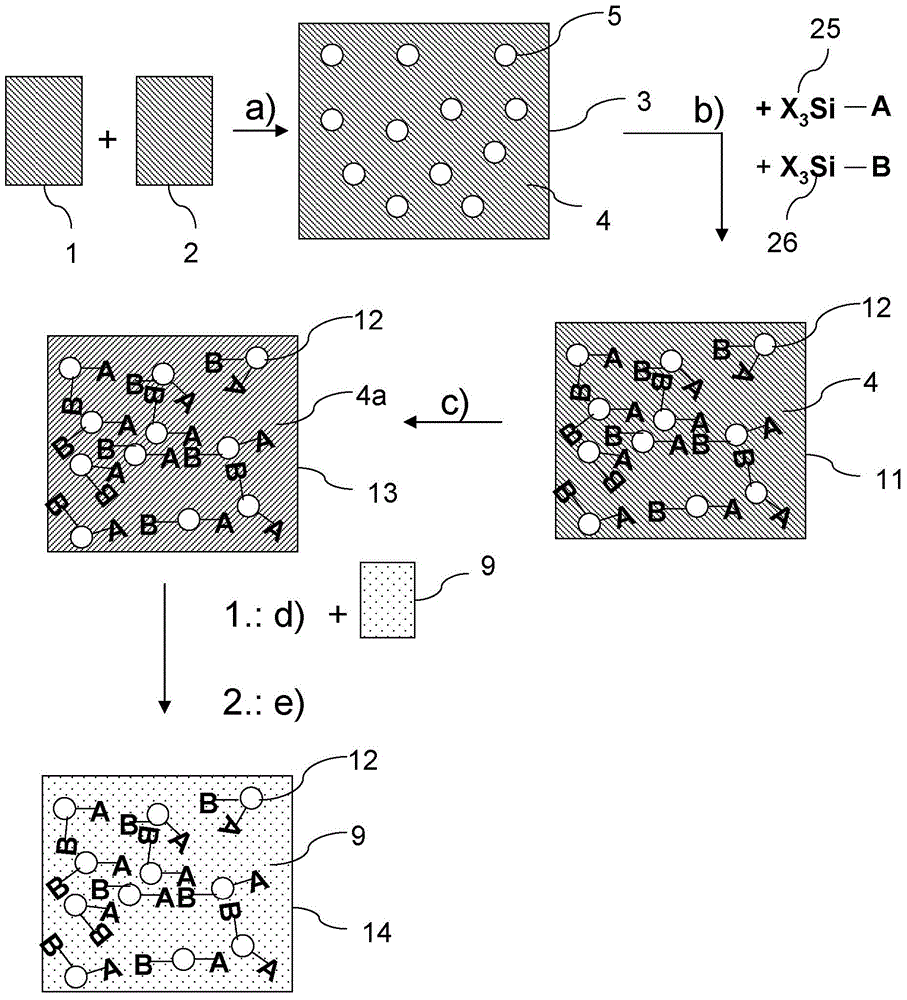

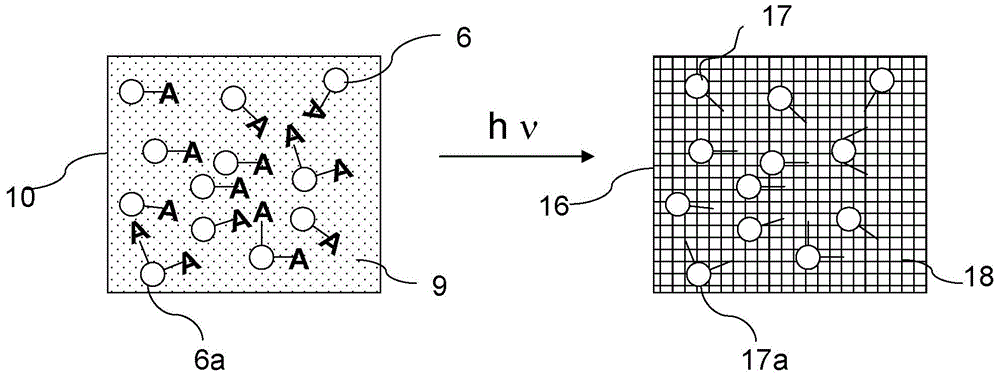

Method used

Image

Examples

Embodiment 1

[0094] Example 1: Using barium perchlorate as precursor and hydroxypropyl cellulose as sol Stabilizer SiO 2 -Dispersion of BaO nanoparticles in di-GMA / TEG-DMA matrix

[0095] Step a): Synthesis of Particles

[0096] Solution A:

[0097] Dissolve 8 g of anhydrous barium perchlorate in 238 ml of ethanol. To stabilize the solution, 1.2 ml of acetylacetone was added. Then, 26.8 ml of TEOS was added to the solution.

[0098] Solution B:

[0099] Mix 278ml of ethanol with 29ml of 25% NH 4 OH solution, and 3 g of hydroxypropyl cellulose (HPC) was added as a sol stabilizer. The solution was stirred until the sol stabilizer was dissolved.

[0100] To start the reaction, solution A was added rapidly to solution B with vigorous stirring. Then, the reaction mixture was stirred for 24 hours. As a result of particle formation, the solution gradually became cloudy.

[0101] Step b): Surface modification

[0102] To silylate the particles synthesized in step a), 2.8 ml ...

Embodiment 2

[0109] Example 2: Using 3-methacryloxypropyltrimethoxysilane (MPTMS) as A sol stabilizer with a di-GMA / TEG-DMA mixture as a matrix monomer SiO 2 - Dispersion of BaO nanoparticles

[0110] Steps a) and b): Synthesis and silanization of particles

[0111] Solution A:

[0112] Dissolve 8 g of anhydrous barium perchlorate in 214 ml of ethanol. To stabilize the solution, 1.2 ml of acetylacetone was added. Then, 12.3 ml of TEOS was added to the solution. Then, 13.1 ml of 3-methacryloxypropyltrimethoxysilane (MPTMS) was added to the solution.

[0113] Solution B:

[0114] Mix 252ml of ethanol with 26ml of 25% NH 4 OH solution mixed.

[0115] To start the reaction, solution B was quickly added to solution A with vigorous stirring. Then, the reaction mixture was stirred for 24 hours. As a result of particle formation, the solution gradually became cloudy.

[0116] Step c): Separation of counter ions

[0117] In order to remove the perchlorate ions present in th...

Embodiment 3

[0122] Embodiment 3: use Ba(OH) 2 as BaO precursor

[0123] Steps a) and b): Synthesis and silanization of particles

[0124] Solution A:

[0125] Put 220ml of ethanol in the reaction vessel, first add 12.3ml of tetraethoxysilane and 13.1ml of 3-methacryloxypropyltrimethoxysilane (MPTMS) under stirring, then add 1.4ml of methacrylic acid to To stabilize the solution, finally, 71.5ml of saturated barium hydroxide solution (i.e. 4.6% Ba(OH) 2 aqueous solution) was added to the mixture.

[0126] Solution B:

[0127] Mix 256ml of ethanol with 85ml of 2M NH 3 Solutions in ethanol were mixed.

[0128] To start the reaction, solution B was quickly added to solution A with vigorous stirring. Then, the reaction mixture was stirred for 24 hours. As a result of particle formation, the solution gradually became cloudy.

[0129] Step c): Separation of counter ions

[0130] In order to remove the methacrylate ions present in the reaction mixture, the solution was filtere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com