Antibacterial, hemostatic dressing and method of manufacture

A hemostatic dressing and a manufacturing method are applied in the field of medical antibacterial hemostatic material production and manufacture, which can solve the problems of poor antibacterial hemostatic effect, difficult mixing of antibacterial and hemostatic materials, etc., and achieves the promotion of blood coagulation reaction, good antibacterial and hemostatic effects, and application Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

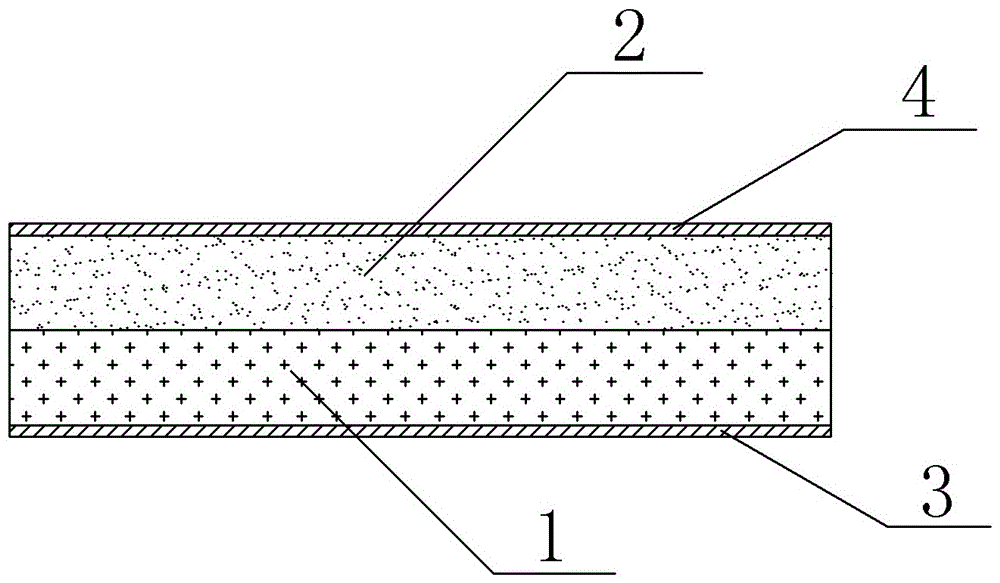

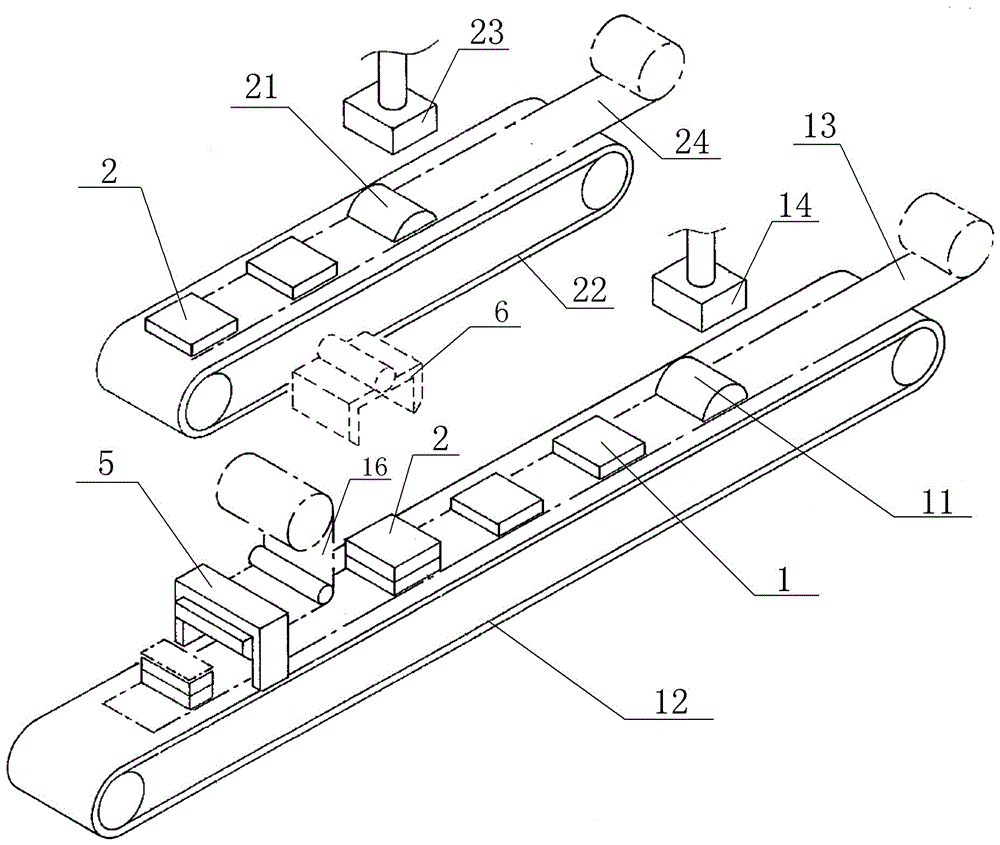

[0030] Embodiment 1: a kind of manufacture method of antibacterial, hemostatic dressing, its flow chart is as figure 2 , image 3 shown, including the following steps:

[0031] (1) Preparation of antibacterial film layer 1: Take 15g of antibacterial material 11 and place it on the first release paper 13 that is conveyed by the conveyor belt 12; a release paper 15 is provided in the first mold 14, and the first mold 14 is pressed down. A mold 14, the antibacterial material 11 is pressed into a square of 10cm × 10cm; the antibacterial material 11 after pressing is dried to a dryness of 50% under the condition of 60°C to form an antibacterial film layer 1; the antibacterial material 11 is the mixture of hexyl alcohol and polyvinyl alcohol mixed with a mass ratio of 1:10;

[0032] (2) Prepare the hemostatic film layer 2: take 15g of the hemostatic material 21 and place it on the release paper 24 that is conveyed by the conveyor belt 22; a release paper is provided in the second...

Embodiment 2

[0035] Embodiment 2: The difference from Example 1 is that the antibacterial material 11 is a mixture of sorbitol and sodium alginate mixed at a mass ratio of 1:10; the preset antibacterial material 11 and hemostatic material 21 The amount is 10g.

Embodiment 3

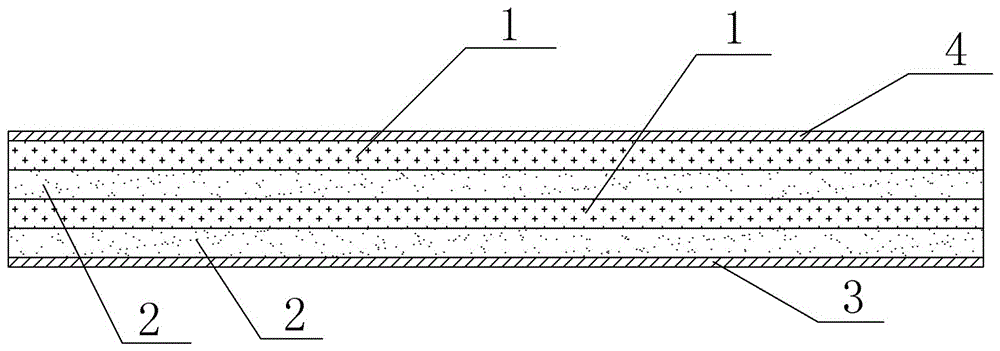

[0036] Embodiment 3: The difference from Example 1 is that the amount of antibacterial material 11 and hemostatic material 21 taken is 30 g, and the shape of the pressed antibacterial film layer 1 and hemostatic film layer 2 is a square of 20 cm × 20 cm; In step (3), two layers of antibacterial film layers and two layers of hemostatic film layers were respectively selected and stacked alternately and then pressed.

[0037] Antibacterial, hemostatic dressing made by embodiment 3, its structure is as figure 2 As shown, the first release paper 3, the hemostatic film layer 2, the antibacterial film layer 1, the hemostatic film layer 2, the antibacterial film layer 1, and the second release paper 4 are sequentially included from bottom to top.

[0038] Unless otherwise specified, the instruments and equipment involved in the above examples are conventional instruments and equipment; the involved industrial raw materials are commercially available conventional industrial raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com