Membrane method extraction system and membrane method extraction process for alanine production

An extraction system and alanine technology, applied in the field of alanine production membrane extraction system and its extraction process, can solve the problems of unsatisfactory treatment adsorption effect, restriction of alanine quality, low product yield, etc., to achieve High-efficiency use and maintenance, convenient maintenance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

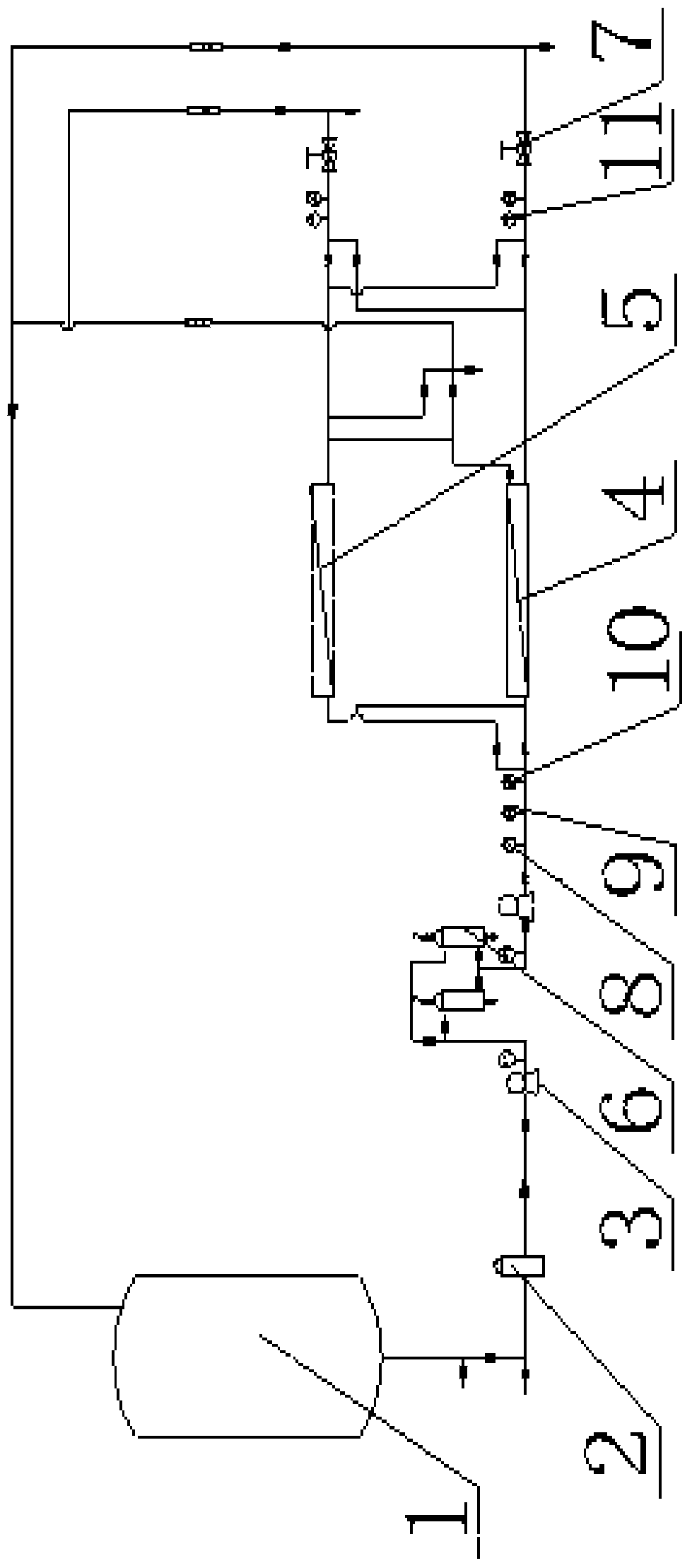

Method used

Image

Examples

Embodiment 1

[0022] 1) 3000kg of alanine fermented liquid with a content of 10% is pumped into the filter by a feeding pump for pre-filtering to filter out larger particles of impurities;

[0023] 2) Pass the pretreated 2982kg alanine fermentation liquid into the organic ultrafiltration membrane system, the operating pressure is within 5bar, and the operating temperature is within 50°C. After the filter pretreatment, the alanine fermentation liquid enters the organic ultrafiltration membrane system. In the membrane filtration system, 245kg of pure water is added during the dialysis process to continue the dialysis through the circulation pump to remove impurities such as bacteria, colonies, mycelia, insoluble proteins and soluble macromolecular proteins, and obtain 2837kg of organic ultrafiltration liquid;

[0024] 3) Transport 2837kg of organic ultrafiltration membrane filtrate to the organic decolorization membrane system by a booster pump, filter at an operating temperature of 45°C and a...

Embodiment 2

[0027] 1) 2500kg of alanine fermented liquid with a content of 9% is pumped into the filter by a feed pump for pre-filtration to filter out larger particles of impurities;

[0028] 2) Pass the pretreated 2450kg alanine fermentation liquid into the organic ultrafiltration membrane system, the operating pressure is within 3bar, and the operating temperature is within 50°C. After the filter pretreatment, the alanine fermentation liquid enters the organic ultrafiltration membrane system. In the membrane filtration system, 200kg of pure water is added during the dialysis process to continue the dialysis through the circulation pump to remove impurities such as bacteria, colonies, mycelia, insoluble proteins and soluble macromolecular proteins, and obtain 2528kg of organic ultrafiltration liquid;

[0029] 3) Transport 2528kg of organic ultrafiltration membrane filtrate to the organic decolorization membrane system by a booster pump, filter at an operating temperature of 45°C and an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com