Continuous reaction production line consisting of multiple serially connected reaction kettles

A reaction kettle and production line technology, applied in the field of continuous reaction production lines, can solve problems such as many failure points, inconsistencies, and reduced working time of the reaction kettle, and achieve the effects of simplified production operation control, safe production environment, and reduced production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

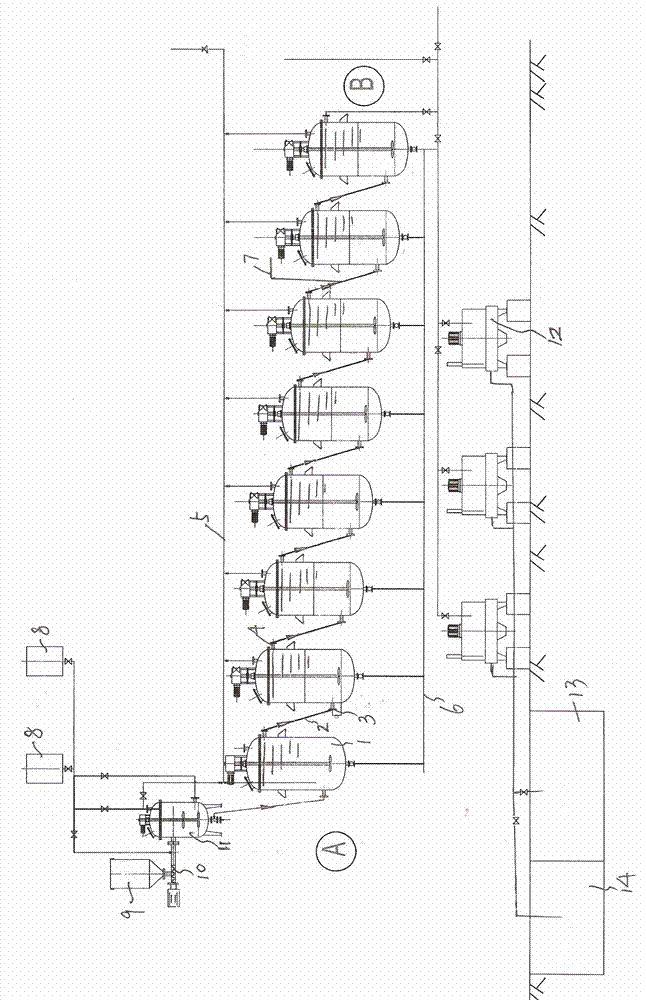

[0024] A continuous reaction production line composed of multiple reactors connected in series. The production line is composed of multiple reactors 1 connected in series. The feed pipe 2 connected between the reactors is connected in series, and the raw materials continuously enter the production line from the feed port of the A end (starting end). , and then they are forced to pass through the reactors in sequence, and after the reaction is completed, they are discharged from the B-end (end) outlet; there is a height difference between the reactors, and they are lowered from the beginning to the end. The position decreases from the beginning to the end in turn; the material enters the kettle from the feed port on the lower side of the previous kettle, then overflows from the overflow port on the upper side, and flows into the lower side of the next kettle by gravity under the action of the drop. feed port. The size of the drop is set according to the nature of the flow in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com