Clamp for copper wire welding

A copper wire and fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as irregular welding joints, affecting the safe use of transformers, affecting welding quality and appearance, etc., to achieve clamping effect Excellent, simple structure, intuitive and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

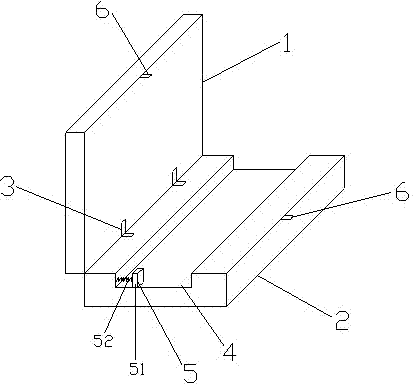

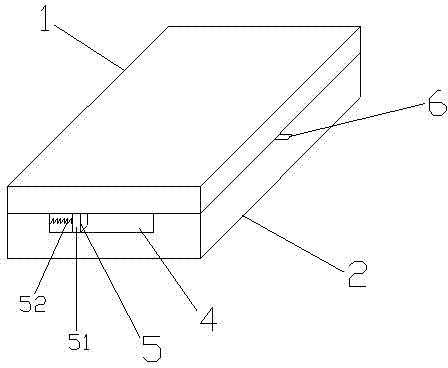

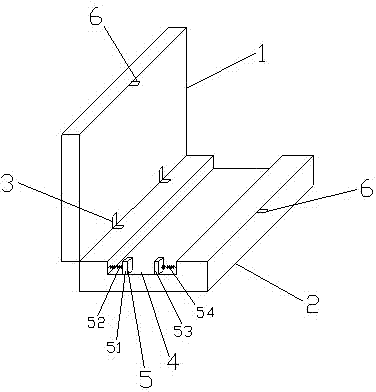

[0020] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0021] like figure 1 and figure 2 The first embodiment shown is a clamp for copper wire welding, which includes an upper clamping block 1 and a lower clamping block 2, which are fastened to each other and arranged in parallel, and are connected at the same end by a movable connector 3, and in addition In the middle part of the lower clamping block 2, there is a copper wire placement groove 4 communicating front and back, and the height of the copper wire placement groove 4 is the diameter of the copper wire; The block assembly 5 is composed of a block 51 and a spring 52 . A fastening part 6 is also provided at the other end of the upper clamping block 1 and the lower clamping block 2 opposite to the movable connecting part 3 . The movable connecting part 3 of the present invention is a hinge connecting part; the fastening part 6 is a buckle structure, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com