Rotational moulding plastic ship and manufacturing method thereof

A manufacturing method and boat technology, which is applied in the construction of ships, hulls, ships, etc., can solve the problems of long manufacturing cycle, prominent safety hazards, crushing, etc., and achieve excellent aging resistance, superior impact resistance, and strong impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

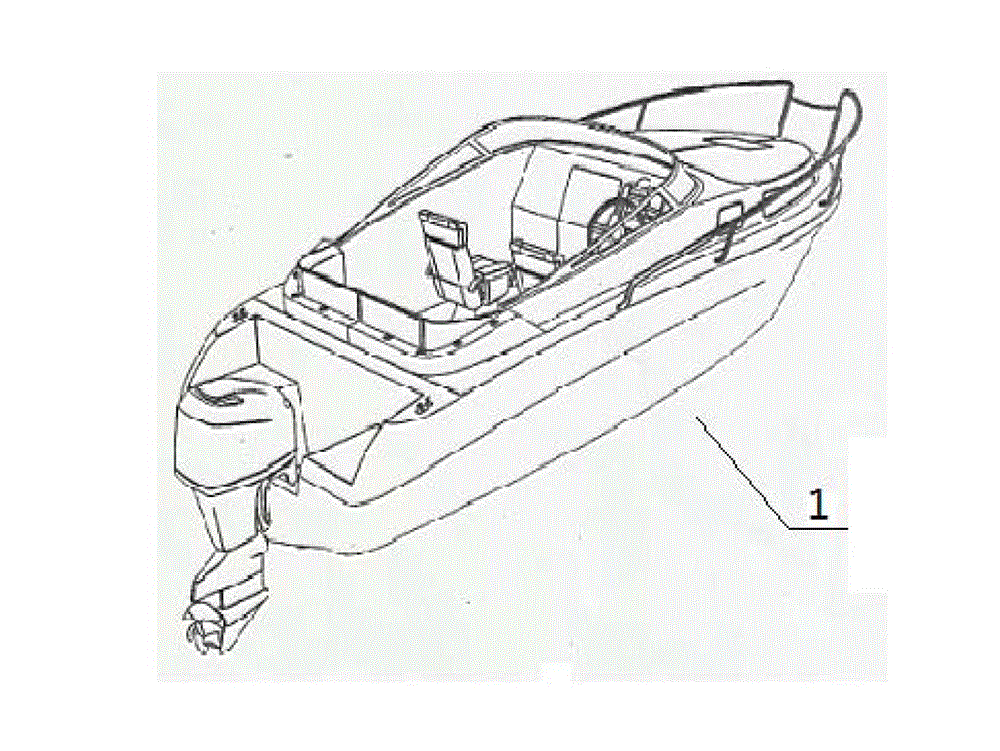

Image

Examples

Embodiment 1

[0043]95 parts of polyolefin, 1 part of PA nylon, 90 parts of HIPS, 5 parts of EPDM rubber, 90 parts of ABS, 5 parts of EPDM rubber, PMMA and PC polymers The modified material is put into the mold cavity of the mold, and the mold is put into the heating chamber of the platform swing machine to be heated, and the whole one-time molding is adopted by the rotational molding process, and the plastic boat is obtained after cooling, shaping and demoulding.

Embodiment 2

[0045] 100 parts of polyolefin, 5 parts of PA nylon, 95 parts of HIPS, 10 parts of EPDM rubber, 95 parts of ABS, 10 parts of EPDM rubber, PMMA and PC polymers The modified material is put into the mold cavity of the mold, and the mold is put into the heating chamber of the platform swing machine to be heated, and the whole one-time molding is adopted by the rotational molding process, and the plastic boat is obtained after cooling, shaping and demoulding.

Embodiment 3

[0047] 97 parts of polyolefin, 2.5 parts of PA nylon, 93 parts of HIPS, 7 parts of EPDM rubber, 92 parts of ABS, 8 parts of EPDM rubber, PMMA and PC polymers The modified material is put into the mold cavity of the mold, and the mold is put into the heating chamber of the platform swing machine to be heated, and the whole one-time molding is adopted by the rotational molding process, and the plastic boat is obtained after cooling, shaping and demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com