Method of breaking the barrel and pouring out the barrel of liquid and semi-condensed waste oil

A waste oil and semi-solidified technology, which is applied in the field of pouring out materials from containers, can solve the problems of breaking through the bottom of the barrel, hurting people, increasing oil-water separation, and potential safety hazards, so as to improve the purification and separation effect and meet the production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

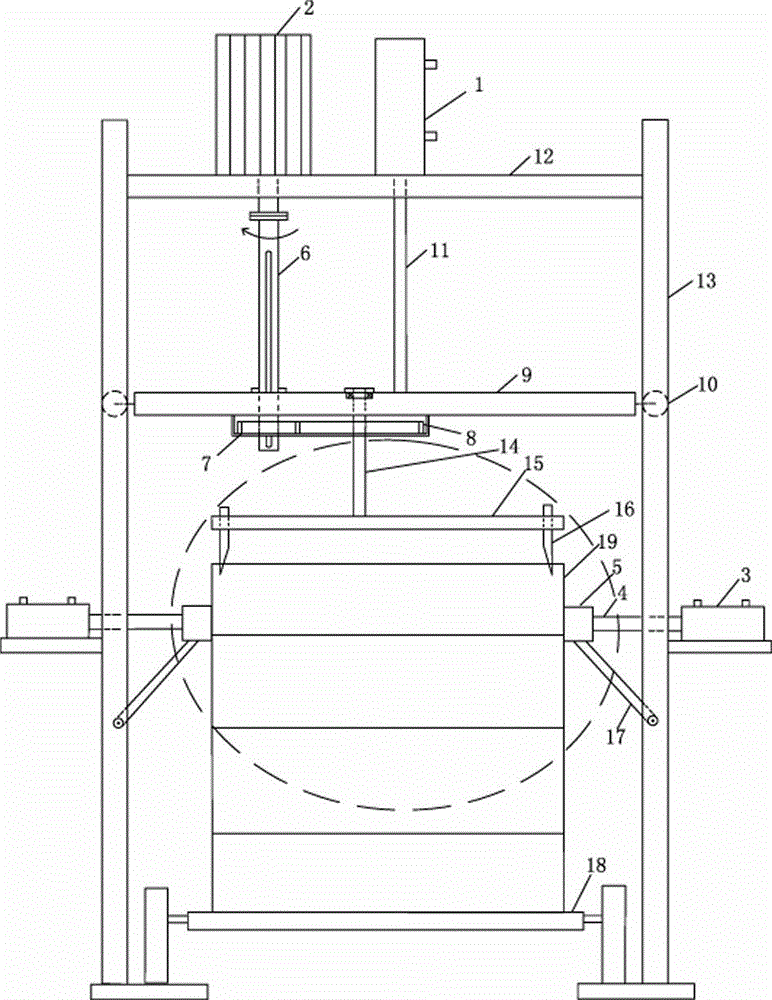

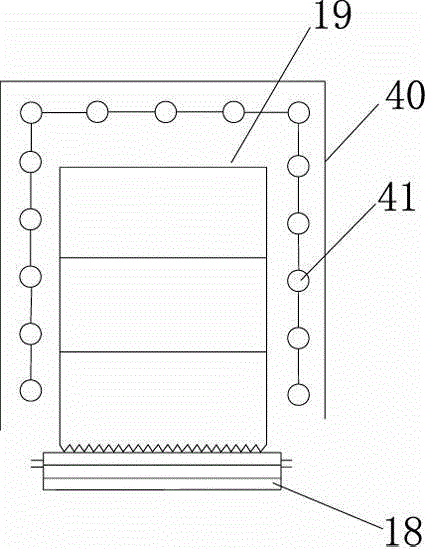

[0020] The method for breaking the barrel and pouring out the barreled liquid and semi-condensed waste oil of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] The method of breaking the barrel and dumping the barreled liquid and semi-condensed solid waste oil of the present invention first completely breaks the barrel lid along the edge of the barrel lid through the barrel breaking machine, and then turns it over by the turning machine until the vibrating machine vibrates and dumps it, and then pours the oil The oil barrels are sent to the drying room to be indirectly heated by steam to melt and recycle a small amount of waste oil adhering to the barrel wall, and finally send the empty barrels to the storage yard; the specific operation steps are as follows:

[0022] Step 1: Use a crane to hoist the barreled waste oil to the chain conveyor, and the conveyor will send the oil barrel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com