Streptolydigin output improving method

A technology for the production of streptolycin, which is applied in the field of increasing the production of streptolycin in the fermentation process, can solve the problems of low production of streptolycin and the impact on the further research, development and utilization of streptolycin, and achieves The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of culture medium and amino acid mother solution:

[0024] ①Seed medium: starch 30g, glucose 5g, yeast extract powder 2g, peptone 4g, MgSO 4 ·7H 2 O0.5g, NaCl0.5g, K 2 HPO 4 1.5g, add water to make up to 1L, steam sterilize at 121℃ for 20min;

[0025] ② Fermentation medium: starch 40g, glucose 5g, peptone 2g, MgSO 4 ·7H 2 O0.5g, NaCl0.5g, K 2 HPO 4 1g, add water to make up to 1L, pH6.5, steam sterilization at 121℃ for 20min;

[0026] ③Proline mother liquor: Weigh 0.3g of proline, dilute to 100mL with ultrapure water, and pass through a 0.2μm sterile filter to obtain sterile proline mother liquor;

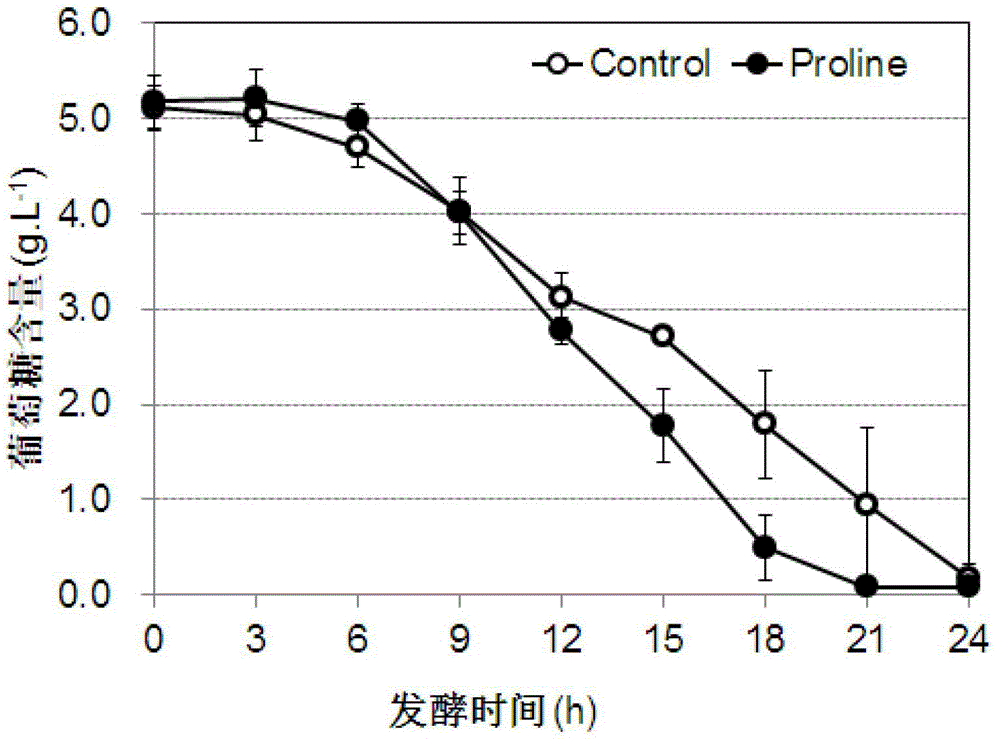

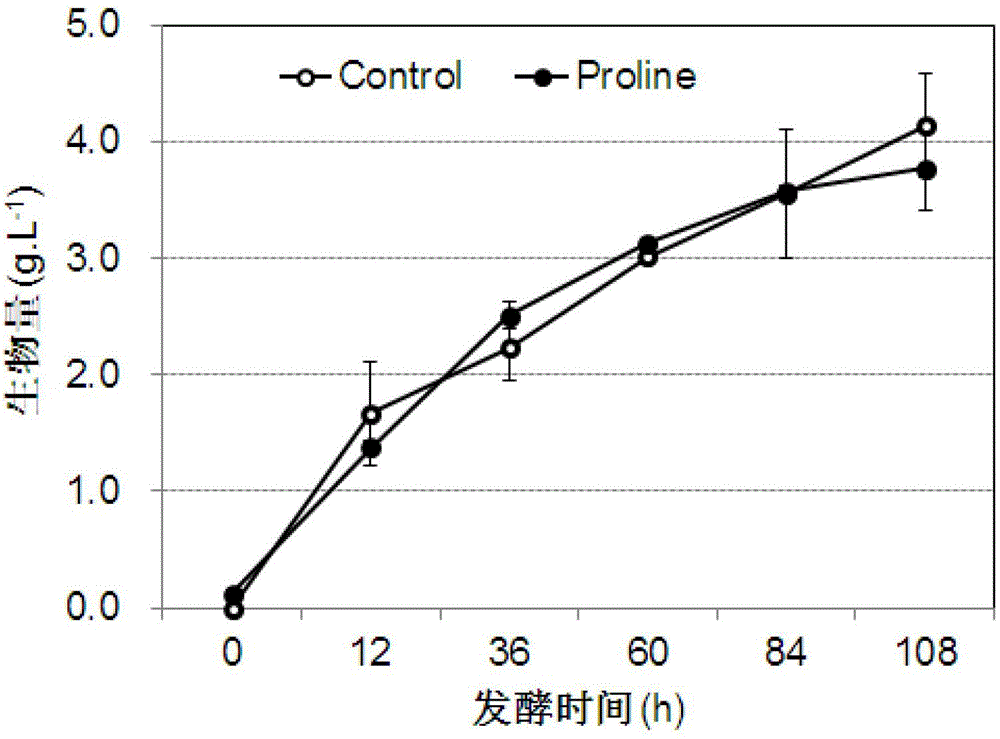

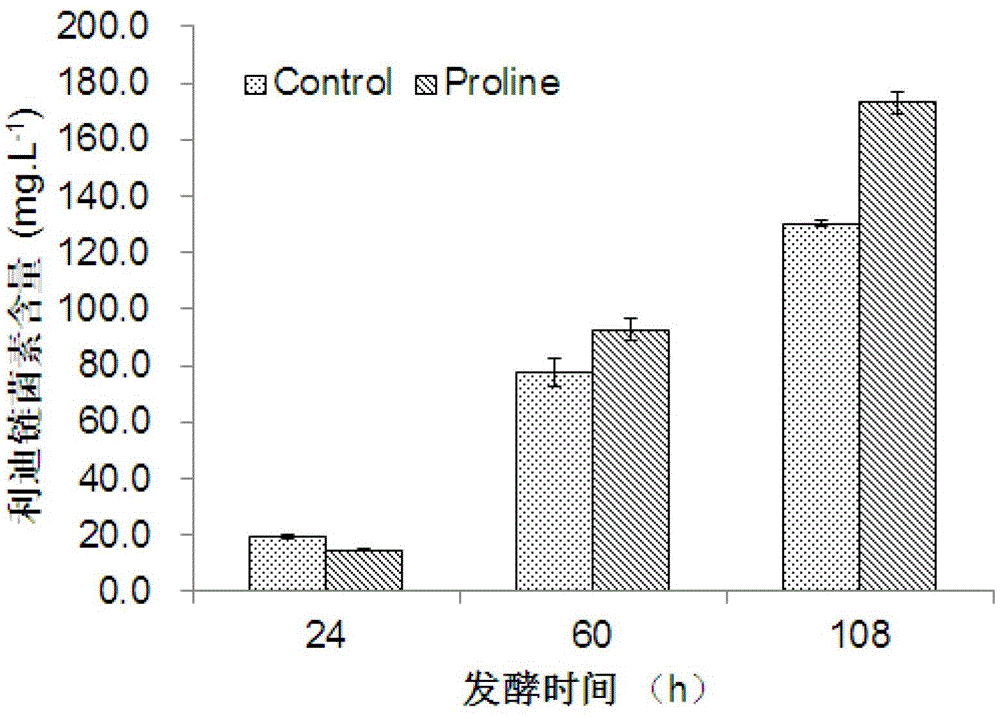

[0027] (2) Seed culture: Streptomyces lydicus (Streptomyces lydicus) E9CGMCC No.3075 slant was inoculated in a 250mL shaker flask containing 50mL seed medium, and cultured for 48h at a shaker speed of 200rpm and a temperature of 28°C to obtain First-class seeds: Inoculate the first-class seeds with a volume ratio of 10% in a 250-mL shaker flask contai...

Embodiment 2

[0036] (1) Preparation of culture medium and amino acid mother solution:

[0037] ①Seed medium: starch 10g, glucose 6g, yeast extract powder 5g, peptone 5g, MgSO 4 ·7H 2 O1g, NaCl1g, K 2 HPO 4 1g, add water to make up to 1L, steam sterilize at 121℃ for 20min;

[0038] ② Fermentation medium: starch 30g, glucose 8g, peptone 3g, MgSO 4 ·7H 2 O1g, NaCl1g, K 2 HPO 4 1g, add water to make up to 1L, steam sterilize at 121℃ for 20min;

[0039] ③Proline mother liquor: Weigh 1g of proline, dilute to 200mL with ultrapure water, and pass through a 0.3μm sterile filter to obtain sterile proline mother liquor;

[0040] (2) Seed cultivation: same as step (2) of Example 1;

[0041] (3) Fermentation by adding proline: Centrifuge 200ml of the secondary seeds at 4000rpm for 10min to obtain mycelium, resuspend the mycelium with 200ml of fermentation medium, and inoculate to the container at an inoculation density of 10% by volume. In a 5L fermenter with a fermentation medium, add 200mL ...

Embodiment 3

[0047] (1) Preparation of culture medium and amino acid mother solution:

[0048] ①Seed medium: 50g starch, 1g glucose, 1g yeast extract powder, 1g peptone, MgSO 4 ·7H 2 O0.1g, NaCl0.1g, K 2 HPO 4 0.1g, add water to make up to 1L, steam sterilize at 121℃ for 20min;

[0049] ② Fermentation medium: starch 10g, glucose 1g, peptone 1g, MgSO 4 ·7H 2 O0.1g, NaCl0.1g, K 2 HPO 4 0.1g, add water to make up to 1L, steam sterilize at 121℃ for 20min;

[0050] ③Proline mother liquor: Weigh 0.1g of proline, dilute to 50mL with ultrapure water, and pass through a 0.1μm sterile filter to obtain sterile proline mother liquor;

[0051] (2) Seed cultivation: same as step (2) of Example 1;

[0052] (3) Fermentation by adding proline: Centrifuge 100ml of the secondary seeds at 3000rpm for 20min to obtain mycelium, resuspend the mycelium with 100ml of fermentation medium, and inoculate to the container at an inoculation density of 5% by volume. In a 5L fermenter with a fermentation medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com