Inert alloy anode for electrolytic aluminum and preparation method thereof

An inert alloy and electrolytic aluminum technology, applied in the field of electrolytic aluminum industry, can solve the problems of alloy anode consumption, poor corrosion resistance, and low oxidation resistance, and achieve the effects of low power consumption, not easy to fall off, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

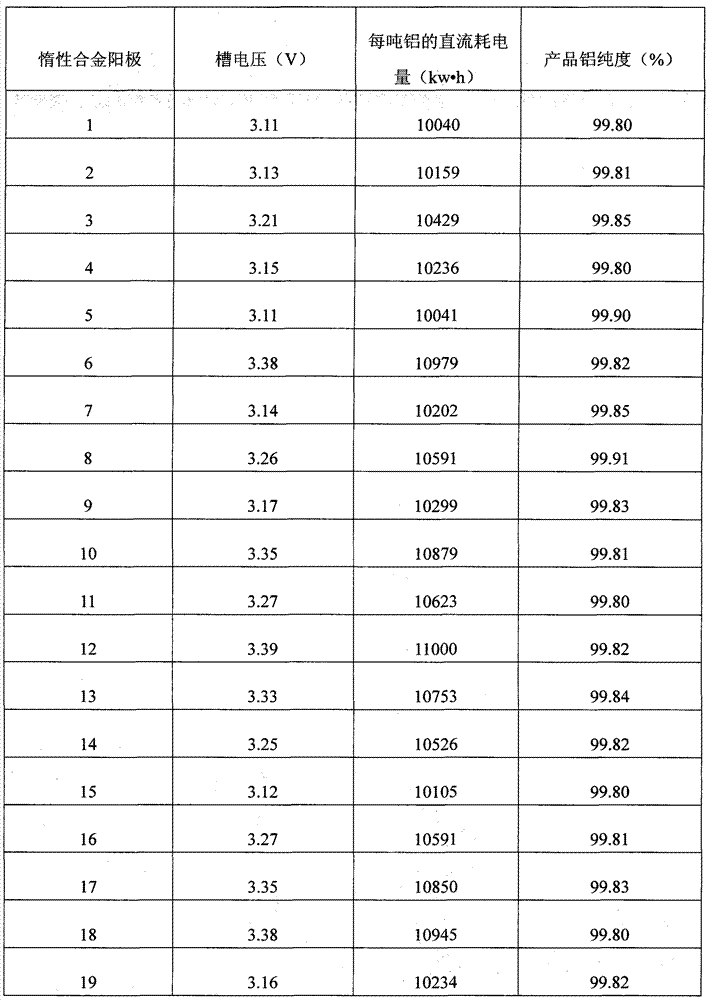

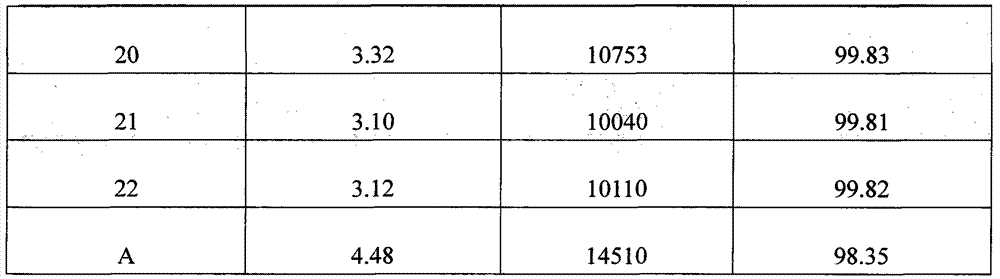

Examples

Embodiment 1

[0032] 40.01 parts by weight of Fe metal blocks, 35.9 parts by weight of Cu metal blocks and 0.19 parts by weight of Sn metal blocks are melted and mixed uniformly under high-speed electromagnetic stirring, quickly cast, and rapidly cooled at a speed of 20-100°C / s to obtain a texture Uniform inert alloy anode1. The density of the inert alloy anode is 8.2g / cm 3 , the specific resistance is 61μΩ·cm, and the melting point is 1400°C.

Embodiment 2

[0034] Melt 80 parts by weight of Fe metal blocks, 0.01 parts by weight of Cu metal blocks and 0.01 parts by weight of Sn metal blocks, mix them uniformly under high-speed electromagnetic stirring, quickly cast, and rapidly cool at a speed of 20-100°C / s to obtain the texture Uniform inert alloy anode2. The density of the inert alloy anode is 7.5g / cm 3 , the specific resistance is 82μΩ·cm, and the melting point is 1369°C.

Embodiment 3

[0036] Melt 60 parts by weight of Fe metal block, 25 parts by weight of Cu metal block and 0.1 part by weight of Sn metal block, mix them uniformly under high-speed electromagnetic stirring, cast quickly, and cool quickly at a speed of 20-100°C / s to obtain the texture Uniform inert alloy anode3. The density of the inert alloy anode is 7.9g / cm 3 , the specific resistance is 84μΩ·cm, and the melting point is 1390°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com