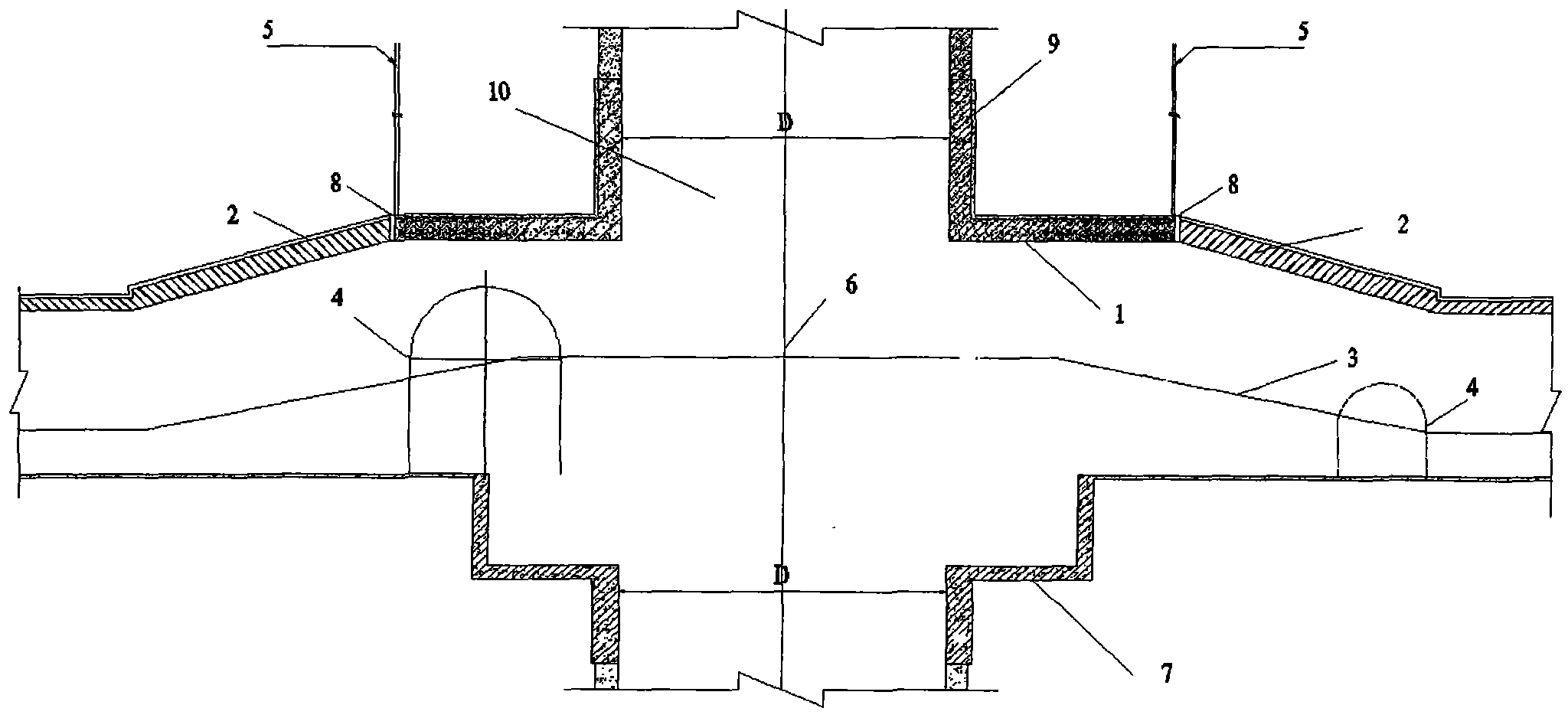

Coal mine deep vertical shaft disturbance-resisting ingate structure

A kind of horse head gate, anti-disturbance technology, applied in shaft lining, mining equipment, shaft equipment, etc., can solve problems such as affecting the safe use of shaft, wall damage, concrete spalling, etc., to achieve wide practicability and ease of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

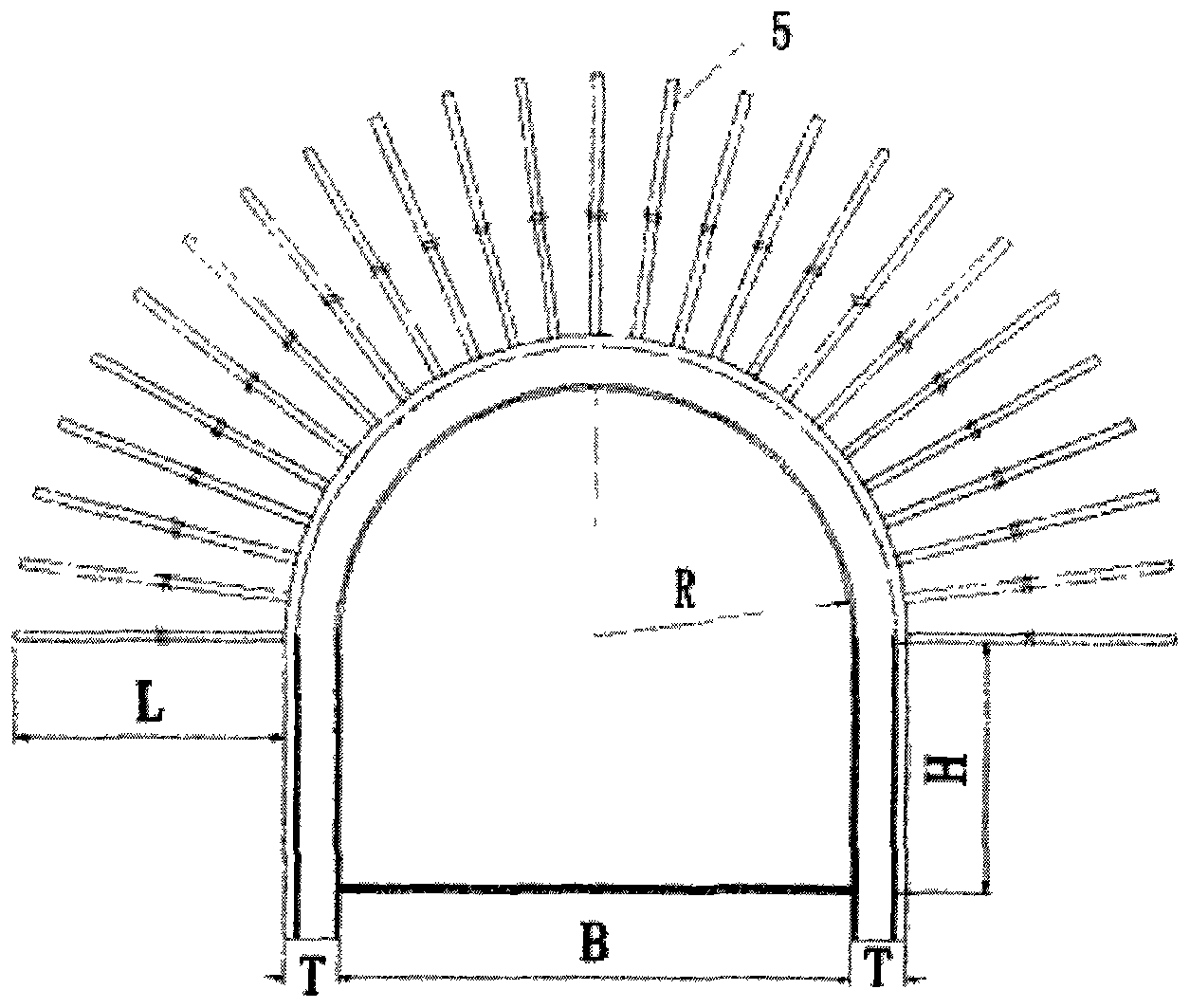

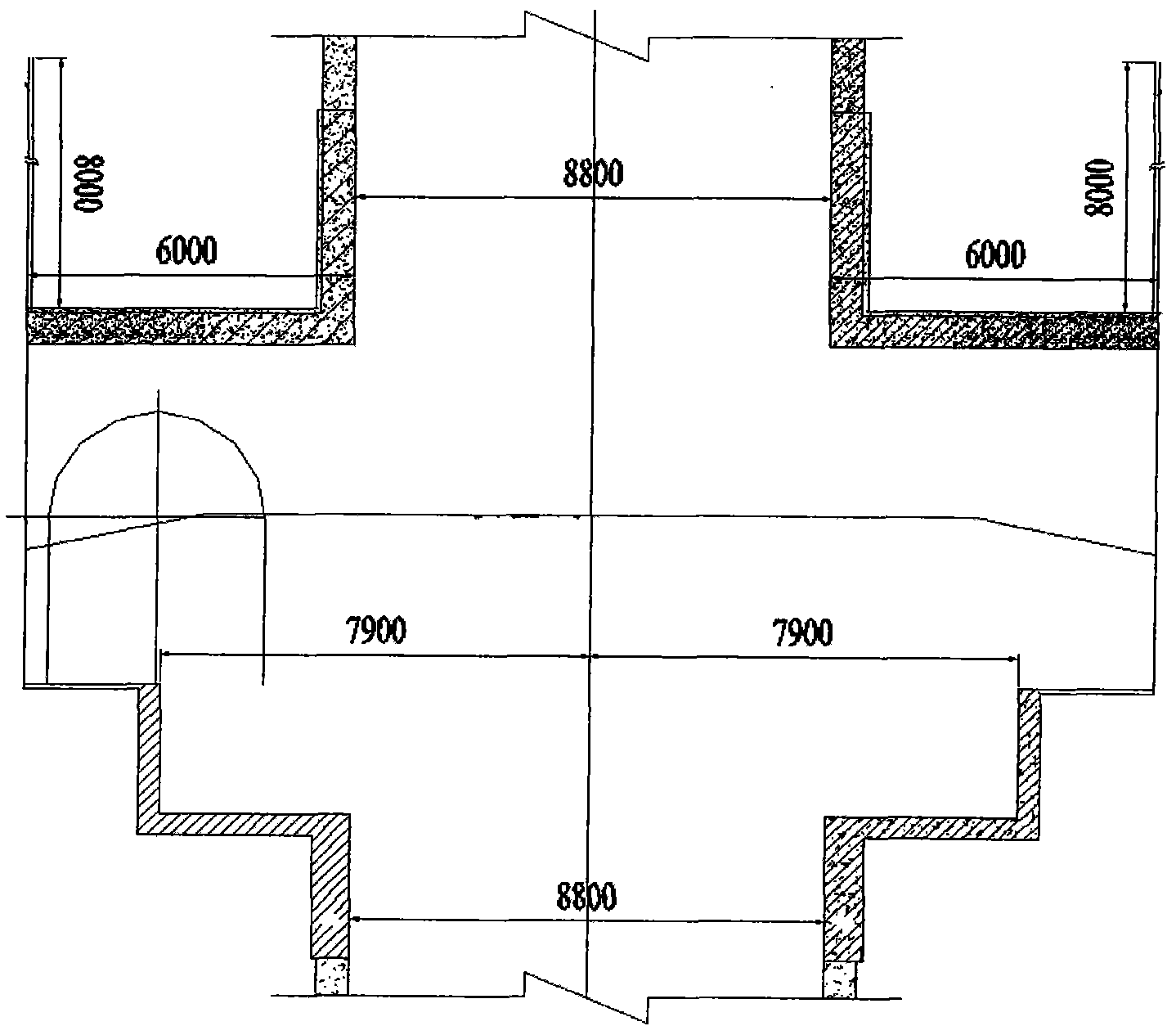

[0019] The horse head gate of a mine is buried 800 meters deep, and it belongs to the horse head gate of the deep shaft. The first pouring section extends to 6m, such as image 3 As shown in the figure, the inner signal chamber was constructed simultaneously with the first pouring section. And set the disturbance-influence isolation hole above the horse head gate. The drill hole diameter is designed to be 75mm, the spacing is 500mm, and the hole depth is 8m, forming an effective disturbance-influence isolation hole. When pouring the second pouring section, a 5mm partition area is reserved and placed 5mm thick foam plastic board to form isolation joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com