An Internal Gear Pump with Radial Compensation

A technology of internal gear pumps and external gears, which is applied to rotary piston type/oscillating piston type pump components, pumps, pump components, etc., and can solve problems such as increased pump leakage, uneven oil pressure, and short service life , to achieve the effects of reduced flow and pressure pulsation, small flow and pressure pulsation, and strong working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

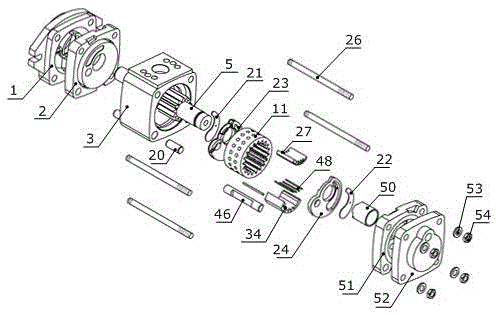

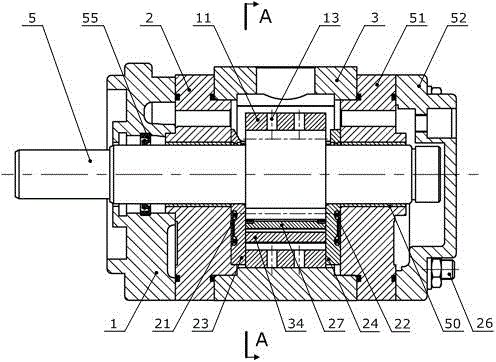

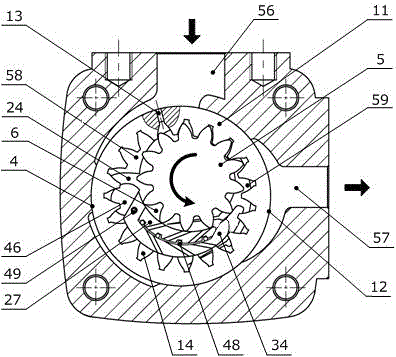

[0032] The specific implementation of the present invention will be described below in conjunction with the drawings and examples.

[0033] Figure 1~5 A schematic diagram of the structure of the present invention is shown. An internal gear pump with radial compensation, comprising an internal ring gear 11 and an external gear 5 meshing with the tooth top 19 of the internal ring gear, the external gear 5 is supported in the pump casing around a parallel axis, so The teeth of the two gears surround a crescent-shaped space that gradually narrows on both sides and is symmetrical. On one side of the space, a large crescent block 34 and a small crescent block 27 are arranged. The large crescent block 34 and the small crescent block 27 make the pump The interior is divided into a high pressure zone 59 and a low pressure zone 58 .

[0034] figure 1Among them, the pump housing of the internal meshing gear pump is composed of a pump body 3, a left connecting cover 2, a right connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com