Electric control split unit pump

A single-body pump and split-body technology, which is applied to fuel injection pumps, liquid fuel feeders, engine components, etc., can solve the problems of inconvenient processing, large space occupation, and difficulty in guaranteeing, and achieve reduced lateral width, horizontal Effect of reduced width, reducing required precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and examples.

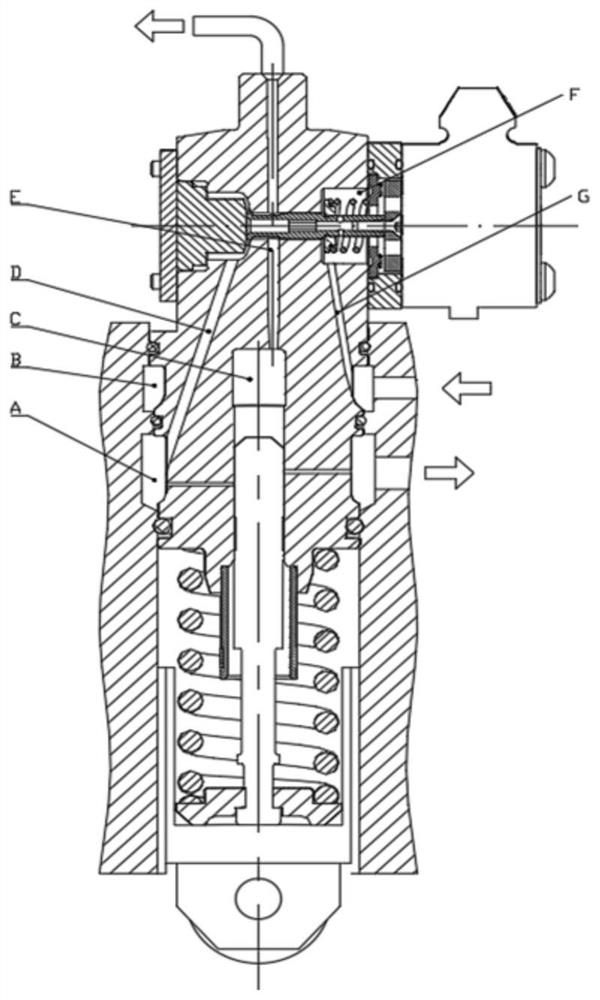

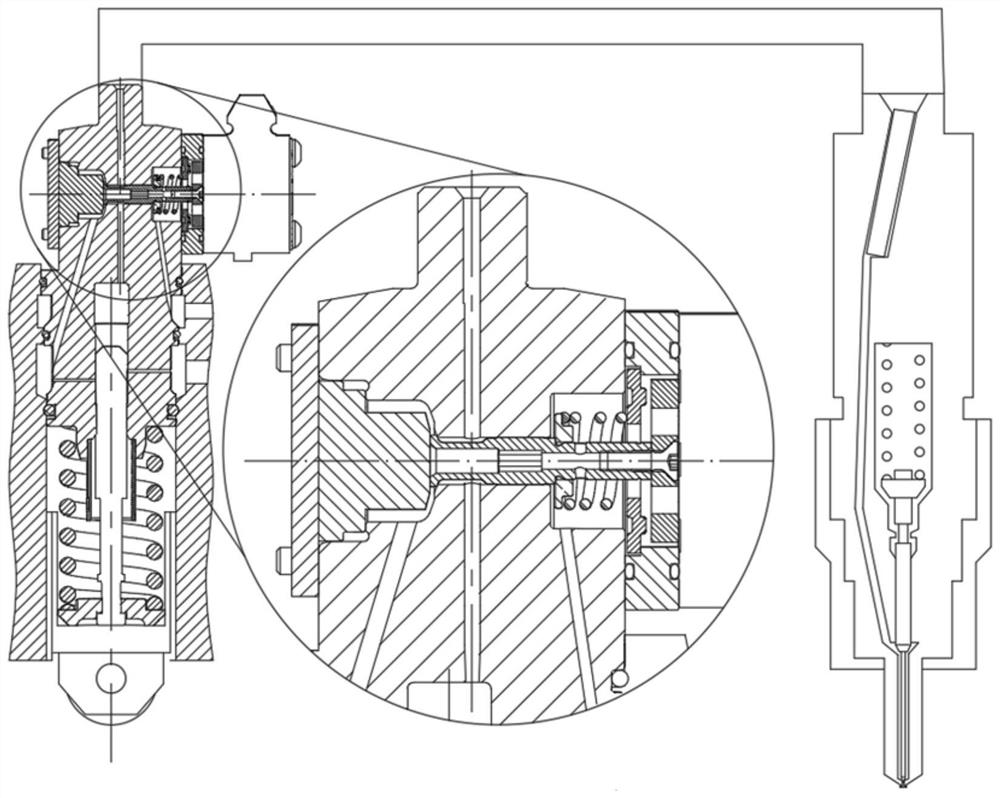

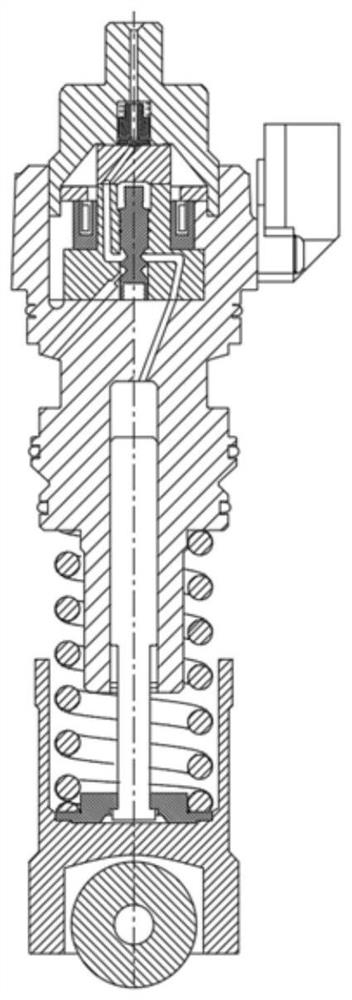

[0047] The present invention provides an electronically controlled split unit pump, which includes a pump body 8 and a valve body 23. The valve body 23 is fixed on the side of the pump body 8 by bolts. The outlet of the oil passage communicates with the pump nozzle oil passage 29, the plunger chamber, and the high-pressure oil passage D in the valve body 23; the low-pressure oil passage in the pump body 8 communicates with the low-pressure oil passage in the valve body 23.

[0048] Such as Figure 13As shown, the high-pressure oil passage in the pump body 8 is divided into oil passage I30, oil passage II31 and oil passage III32; Road III32 is arranged obliquely, one end communicates with high-pressure oil passage D in valve body 23, and there is a bend II34 between the two, and the other end communicates with oil passage II31; oil passage II31 is vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com