A New High Efficiency Smokeless Backburning Boiler

A high-efficiency and new technology, applied in the field of hot water boilers, can solve the problems of poor anti-burning effect, unreasonable setting of inclination angle and size of coal leakage gap, unreasonable setting of high and low positions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

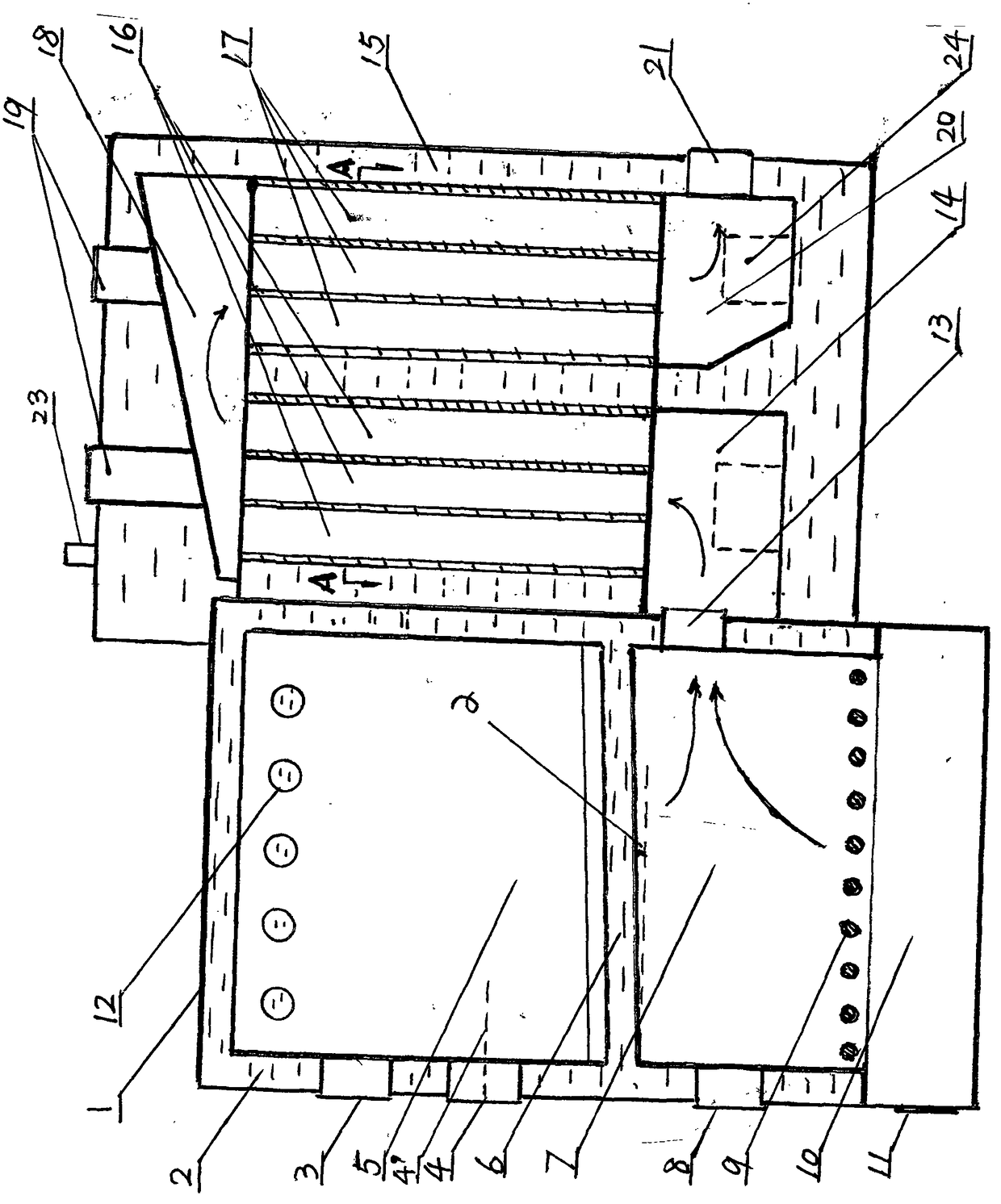

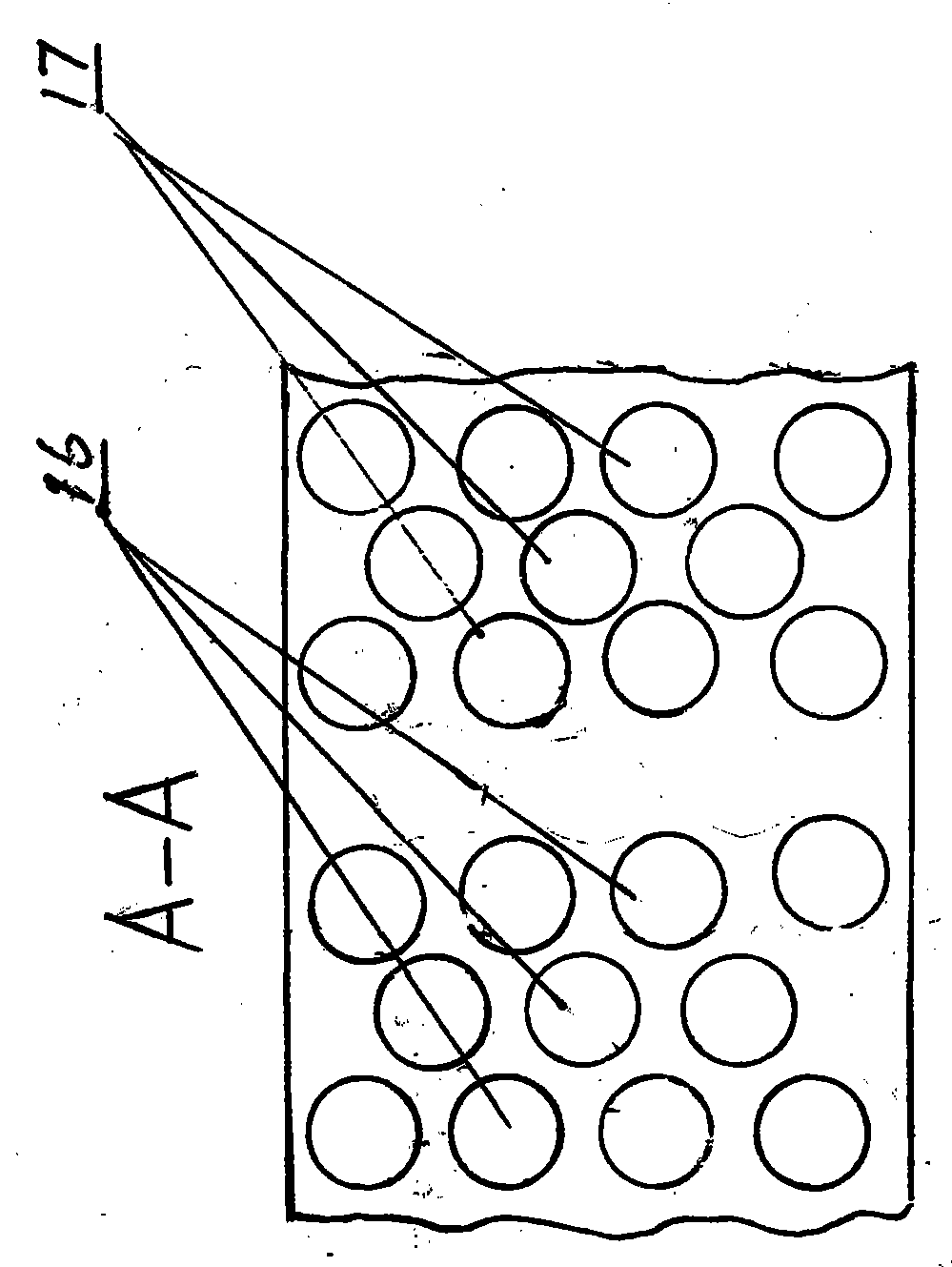

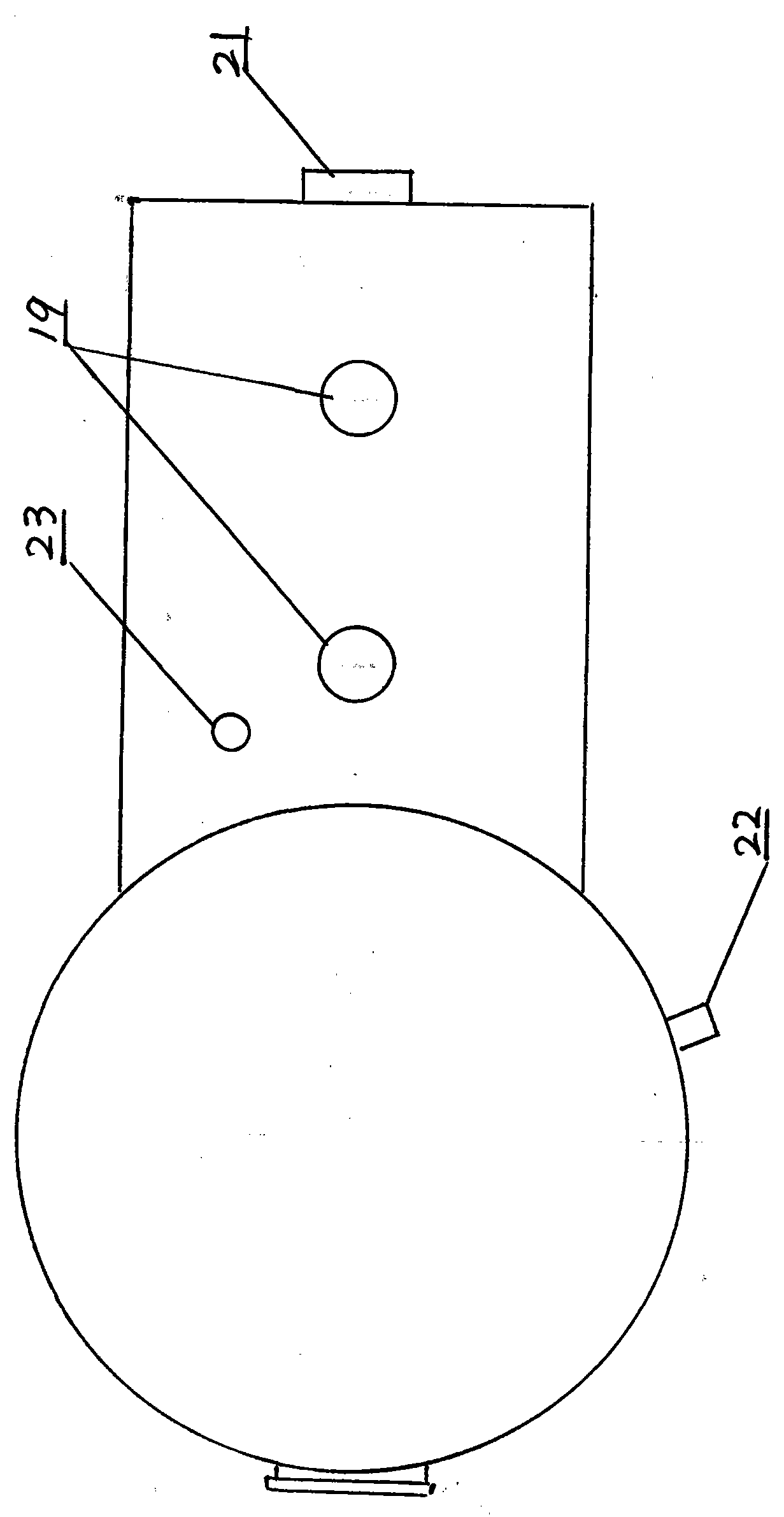

[0017] The accompanying drawings of the description show an embodiment of the present invention. The reverse combustion boiler includes a cylindrical furnace body, a water bag interlayer of the furnace body, a coal feeding furnace door, a water pipe reverse combustion furnace grate, a combustion chamber, an ash chamber, a fire passage, a flue gas residual hot water bag and a smoke exhaust port. The water pipe anti-burning furnace grate 6 is located in the middle part of the furnace body. The combustion chamber includes a dry distillation combustion chamber 5 above the water pipe reverse combustion furnace grate and a reverse combustion combustion chamber 7 under the water pipe reverse combustion furnace grate. The chamber 7 is provided with an operating furnace door 8 on the front side of the furnace body. The rear side of the combustion chamber is provided with a burner port 13 connected to the exhaust pipe of the residual hot water bag of the flue gas, and the exhaust pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com