A solution spray type frost-free air source heat pump device

An air-source heat pump and spray technology, which is applied in the field of refrigeration technology and air-source heat pump, can solve problems such as the inability to avoid frost for a long time, the deterioration of the heat transfer performance of the heat exchanger, and the shortening of the frost-free running time. The effect of controllable and adjustable volume, reducing condensation temperature, improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0039] The solution spray type frost-free air source heat pump of the present invention has a heating mode, a regeneration mode and a cooling mode.

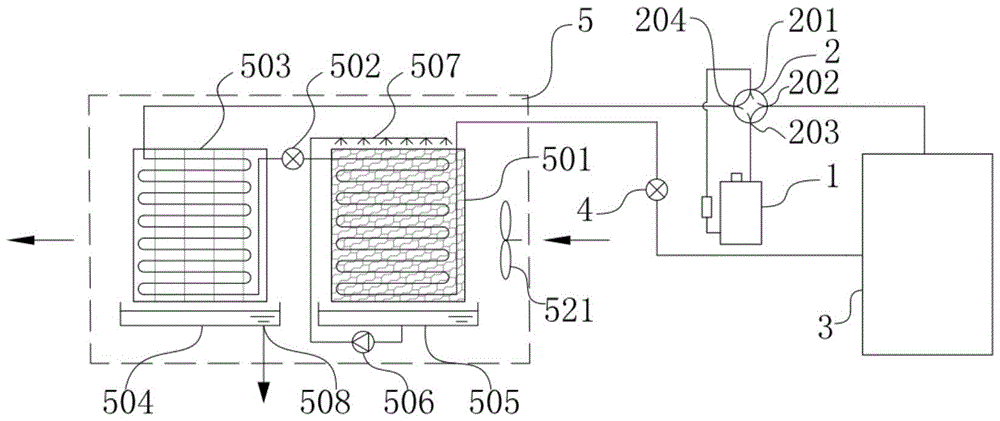

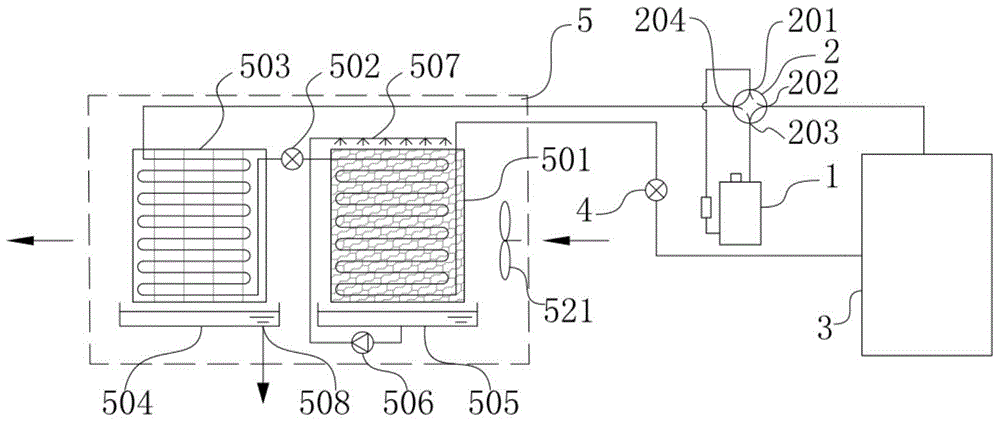

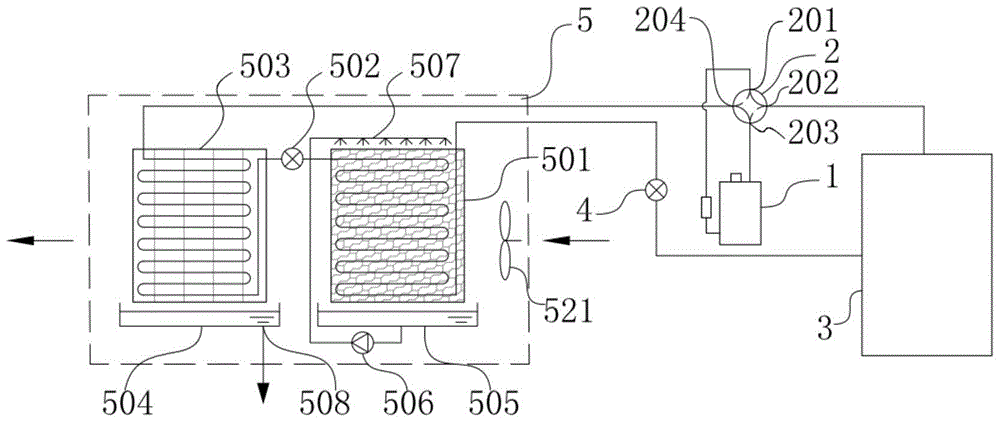

[0040] see figure 1 , in heating mode: No. 1 port 201 of the four-way valve is connected to No. 4 port 204, No. 2 port 202 is connected to No. 3 port 203, the first expansion valve 4 and the second expansion valve 502 normally throttle, the system Enter heating mode. The refrigerant is compressed into a high-temperature and high-pressure gas by the compressor 1, and enters the indoor heat exchanger 3 through the four-way valve 2 to condense into a high-pressure saturated liquid. The heat is evaporated and absorbed in the heater 501 , and after the secondary throttling by the second expansion valve 502 , it is completely evaporated and absorbed in the finned evaporator 503 to become superheated gas. Finally, the refrigerant returns to the compressor 1 through the four-way valve 2 to complete a heating cycle. The air first passe...

specific Embodiment 2

[0044] The following describes the specific flow and working principle of the present invention in the heating mode, regeneration mode and refrigeration mode when the technical solution of the air circulation system is adopted.

[0045] see Figure 4 , in heating mode: No. 1 port 201 of the four-way valve is connected to No. 4 port 204, No. 2 port 202 is connected to No. 3 port 203, the first expansion valve 4 and the second expansion valve 502 normally throttle, and the second expansion valve 4 The first air valve 509 and the second air valve 510 are opened, the circulation air valve 511 is closed, and the system enters the heating mode. The refrigerant is compressed into a high-temperature and high-pressure gas by the compressor 1, and enters the indoor heat exchanger 3 through the four-way valve 2 to condense into a high-pressure saturated liquid. The heat is evaporated and absorbed in the heater 501 , and after the secondary throttling by the second expansion valve 502 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com