Device and method for measuring glass thickness by linear frequency modulation multi-beam laser heterodyne second harmonic method

A linear frequency modulation and laser heterodyne technology, which is applied in the field of optical measurement, can solve the problems of large error and single measurement result, and achieve the effect of satisfying measurement accuracy, improving operation speed and realizing large-scale thickness detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

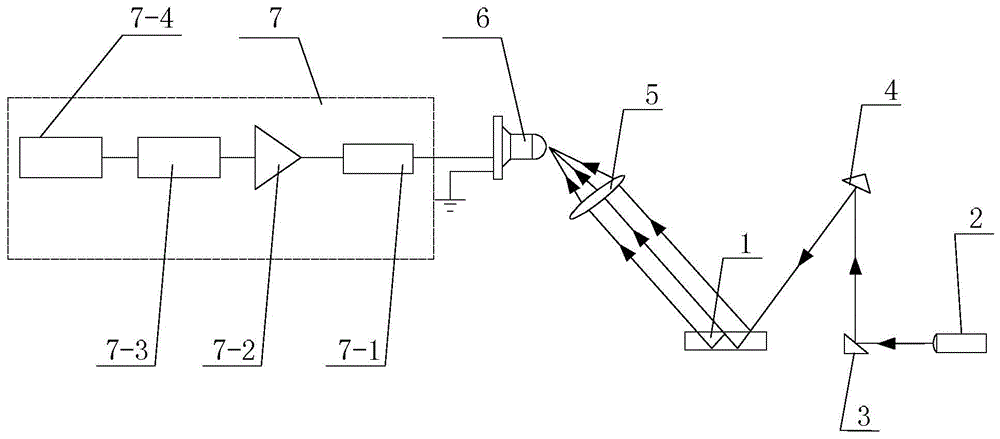

[0043] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the device for measuring glass thickness by chirp multi-beam laser heterodyne second harmonic method described in this embodiment, it includes the plate glass 1 to be tested, is characterized in that, it also includes chirp laser 2, the first Plane mirror 3, second plane mirror 4, converging lens 5, photodetector 6 and signal processing system 7,

[0044] After the linearly polarized light emitted by the chirp laser 2 is reflected by the first plane mirror 3 and the second plane mirror 4, it is obliquely incident on the front surface of the flat glass 1 to be tested, and the light beam transmitted through the front surface of the flat glass 1 to be tested is After being reflected by the rear surface of the flat glass 1 to be tested, the light beam reflected by the front surface of the flat glass 1 to be tested is converged by the converging lens 5 onto the photosensitive surfa...

specific Embodiment approach 2

[0045] Specific implementation mode two: the following combination figure 1 Describe this embodiment, this embodiment will further illustrate embodiment one, the signal processing system 7 described in this embodiment consists of a filter 7-1, a preamplifier 7-2, an analog-to-digital converter 7-3 and a digital signal processor DSP7-4 composition,

[0046] The photoelectric detector 6 outputs an electrical signal to the filter 7-1 of the signal processing system 7, and after being filtered by the filter 7-1, it is sent to the preamplifier 7-2, and the preamplifier 7-2 amplifies the received signal and outputs an analog signal The signal is sent to the analog-to-digital converter 7-3, and the analog-to-digital converter 7-3 converts the analog signal into a digital signal and sends it to the digital signal processor DSP7-4, and the digital signal processor DSP7-4 processes the received digital signal , to obtain the thickness d of the flat glass 1 to be measured.

[0047] In ...

specific Embodiment approach 3

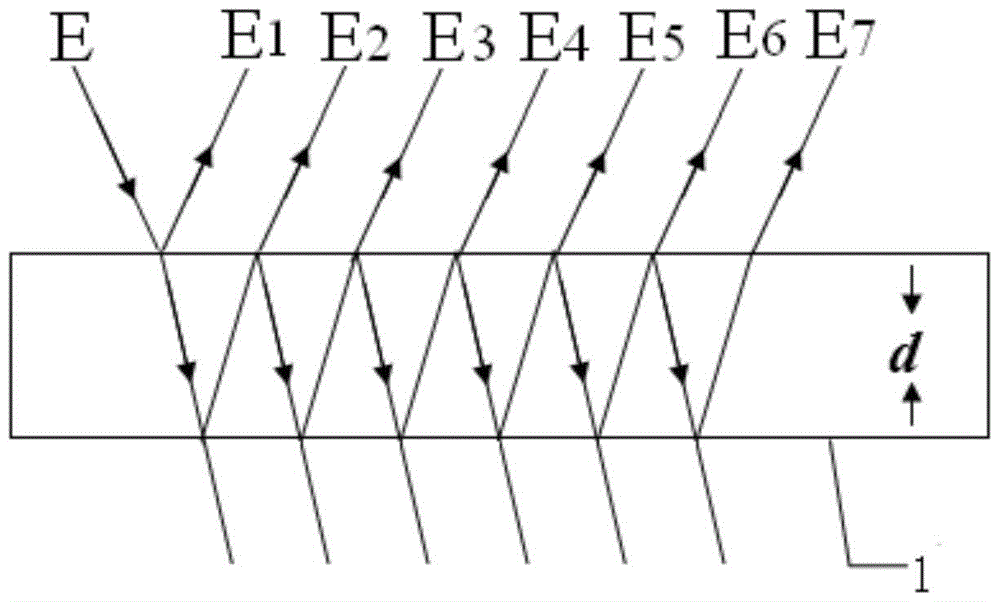

[0048] Specific implementation mode three: the following combination figure 1 and figure 2Describe this embodiment, this embodiment is to adopt the above-mentioned device for measuring glass thickness by the chirp multi-beam laser heterodyne second harmonic method to realize the method for measuring glass thickness by the chirp multi-beam laser heterodyne second harmonic method, the method The process is:

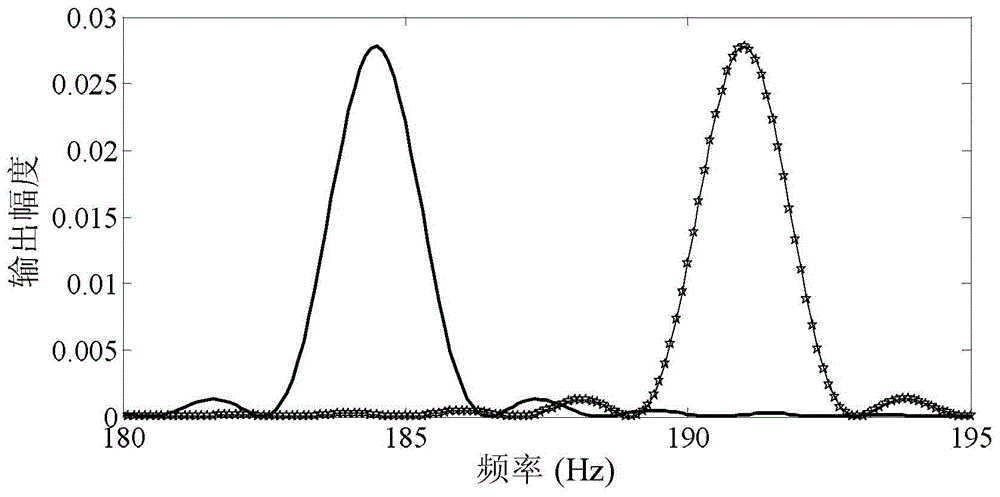

[0049] First, turn on the chirp laser 2 to make it emit linearly polarized light, and make the photodetector 6 start to receive the beam signal, and the digital signal processor DSP7-4 continuously collects the electrical signal output by the photodetector 6, and analyzes the collected difference Frequency signal processing, according to the relationship between frequency and thickness:

[0050] f=Kd,

[0051] Obtain the thickness d of the flat glass 1 to be tested:

[0052] d=f / K,

[0053] In the formula, f is the frequency of the heterodyne signal, and K is the prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com