High-precision three-dimensional shape measurement method for jump object

A three-dimensional surface, high-precision technology, used in measuring devices, optical devices, instruments, etc., can solve problems such as resolution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for high-precision three-dimensional surface shape measurement of a jumping object is characterized in that it includes the following steps:

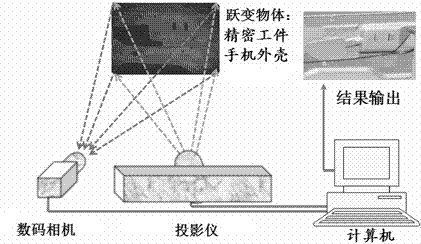

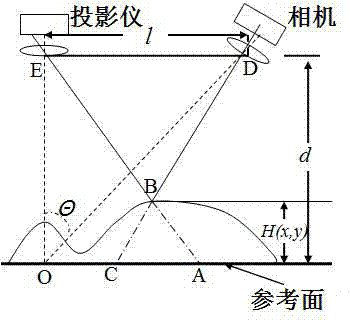

[0058] A. Set up the experimental measurement system: the system mainly includes a digital camera, projector, object to be measured, computer and bracket. Adjust the system so that the digital camera can capture the fringe pattern on the surface of the jumping object to be measured, and at the same time ensure that the line connecting the optical center of the projector and the optical center of the camera is perpendicular to the projection optical axis.

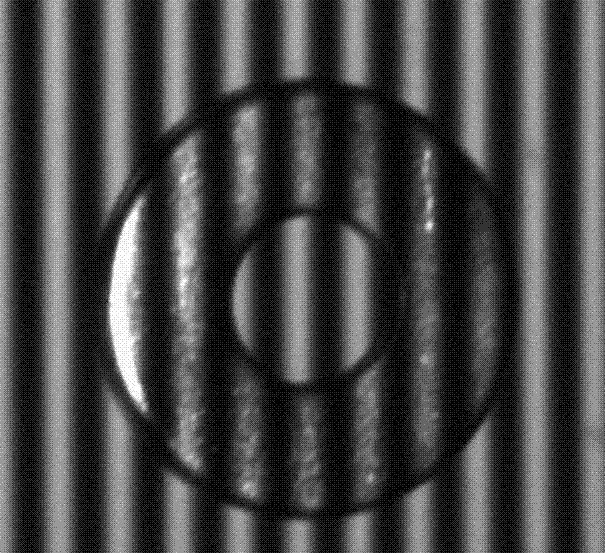

[0059] B. The computer controls the projector to generate and project a standard sinusoidal fringe pattern, and the digital camera shoots the deformed fringes reflected by the surface of the transition object. The light intensity of the deformed fringes can be expressed as:

[0060] I(x,y)=A(x,y)+B(x,y)cos[2πf 0 (x,y)x+φ(x,y)] where I(x,y) represents the light intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com