Grouting and chemical electro osmosis combined discrete material pile model testing device and testing method

A model test device and a technology of bulk material piles, applied in the field of model tests, can solve the problems of limited wide application, high cost, and inaccurate measurement results, and achieve the effects of avoiding irrationality, saving resources, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

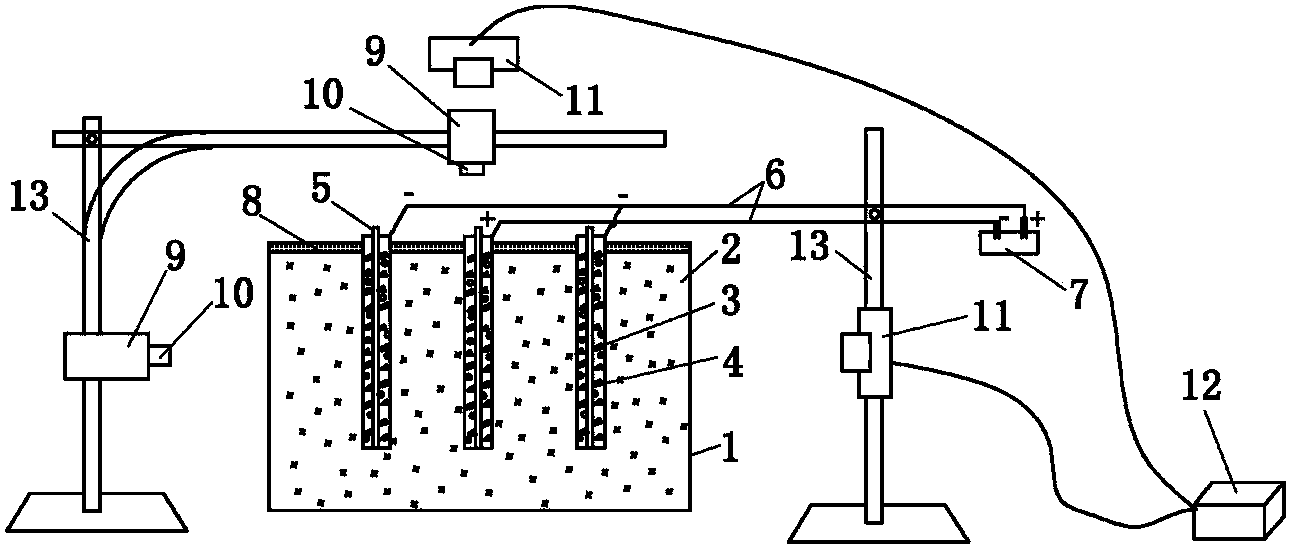

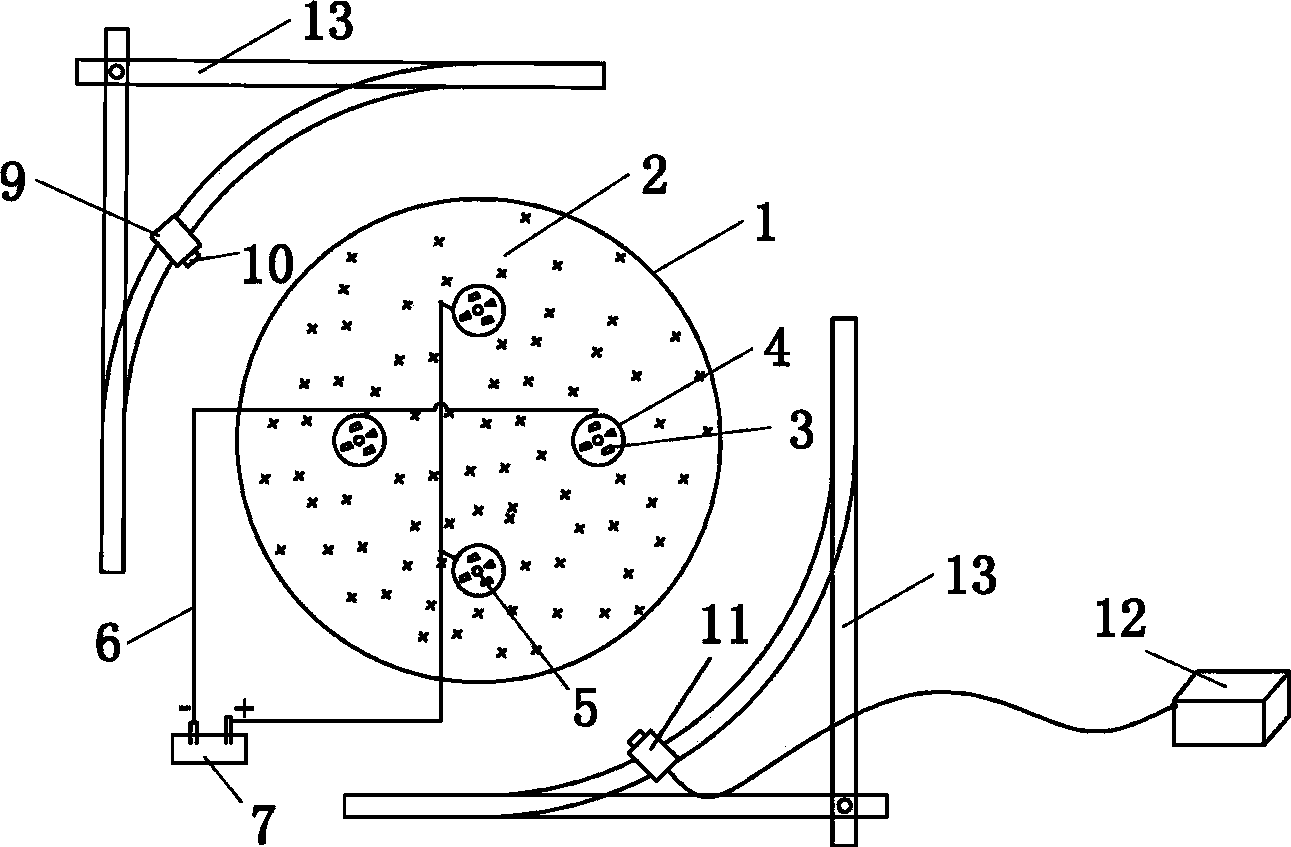

[0050] Depend on figure 1 , figure 2 It can be seen that a grouting joint chemical electroosmotic dispersion material pile model test device includes a transparent model tank 1, a transparent pressure plate 8 is provided on the top of the transparent model tank 1, a bulk material pile 3 is arranged in the tank, and a bulk material pile 3 is arranged in the tank. The electric geogrid 4 is pre-embedded on the outside of the pile 3, and the top of the electric geogrid 4 is respectively connected to the positive and negative poles of the DC power supply 7 through the wire 6, and the grouting pipe 5 is pre-embedded in the center of the pile body; the bulk material pile 3 is simulated by water-soluble transparent soil, and soil 2 around the pile is simulated by oil-soluble transparent soil; the outer side and upper part of the transparent model tank 1 are provided with a laser source installed on the moving mechanism 13, and the front surface outside the transparent model tank 1, ...

Embodiment 2

[0079] When it is necessary to prepare transparent soil simulating saturated clay, when preparing materials, choose baked quartz sand particles with a particle size of ≤0.074mm;

[0080] When mixing, first put the prepared pore liquid in the transparent model tank 1, and pour the baked quartz sand particles into the transparent model tank 1 slowly, uniformly and dispersedly, continuously stir to discharge the air bubbles during the pouring process, and keep Baked quartz sand particles are always below the surface of the pore liquid;

[0081] When the baked quartz sand particles with a particle size of ≤0.074mm are selected in the preparation, they are consolidated in a consolidation instrument after vacuuming, and the OCR value of the consolidation degree is 0.8-3.

[0082] The OCR value of the degree of consolidation in this embodiment is 0.8;

[0083] The rest are the same as embodiment 1.

Embodiment 3

[0085] When preparing materials, choose baked quartz sand particles 0.25㎜≤particle size<0.5㎜ as 10%, 0.5㎜≤particle size<1.0㎜ as 40%, 1.0㎜≤particle size<1.5㎜ as 35%, 1.5㎜ ≤Particle size≤2.0㎜ is 15%, by weight, the total is 100%, mix them evenly;

[0086] When mixing, the density of the control sample is 40%.

[0087] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com