An automated process safety monitoring system based on modbus protocol

A process safety and monitoring system technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems that the Modbus protocol cannot communicate with each other, and cannot realize direct linkage control of slave machines, so as to improve safety redundancy , simple structure, and the effect of improving timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

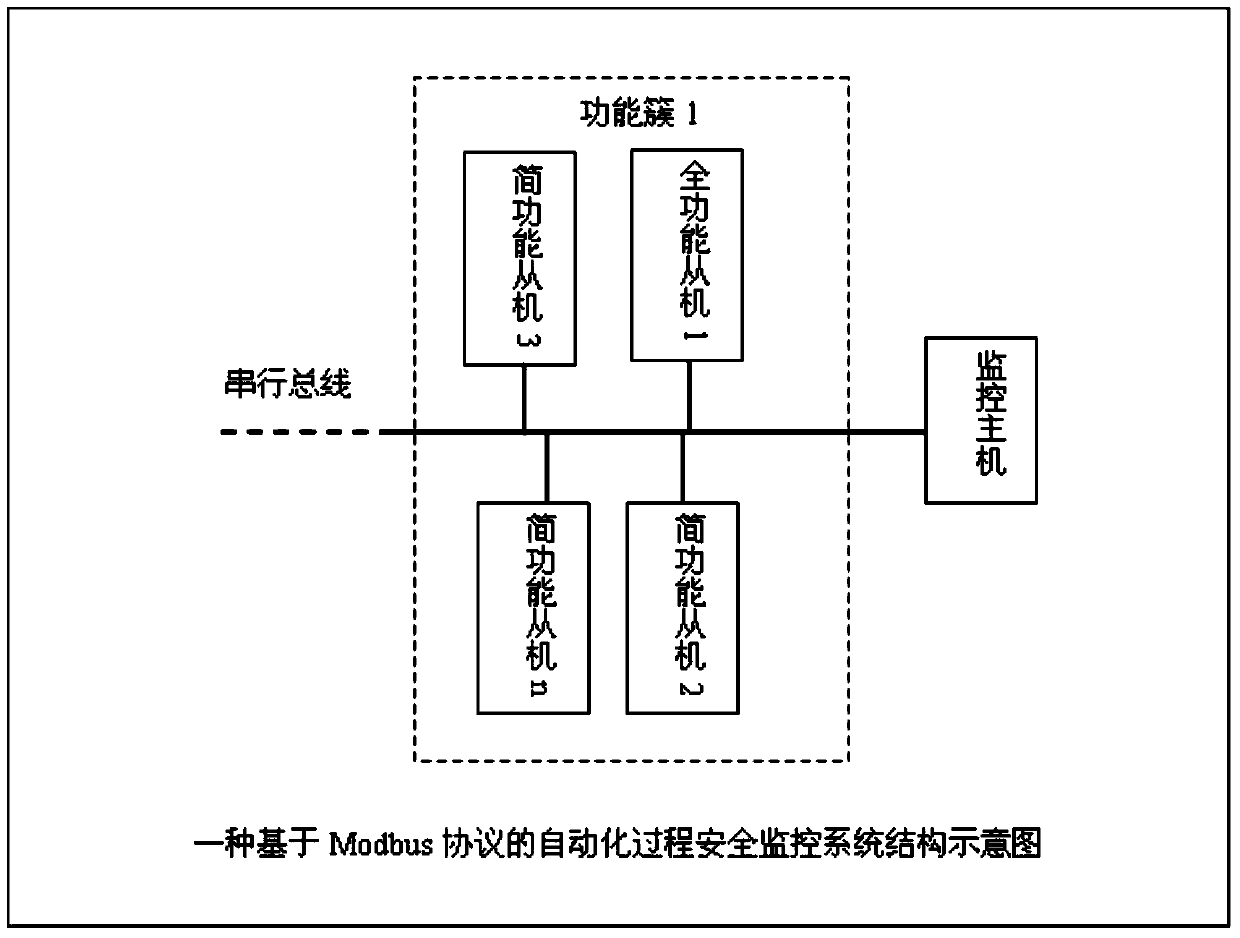

[0026] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings. Such as figure 1 As shown, an automated process safety monitoring system based on the Modbus protocol, as a safety protection system in the automated production control process, is independent of the automated production process control, and monitors the safety of the production device online in real time. In some cases, it does not need to go through the production automation control system, and the process safety monitoring system directly sends an interlock signal to protect the on-site equipment.

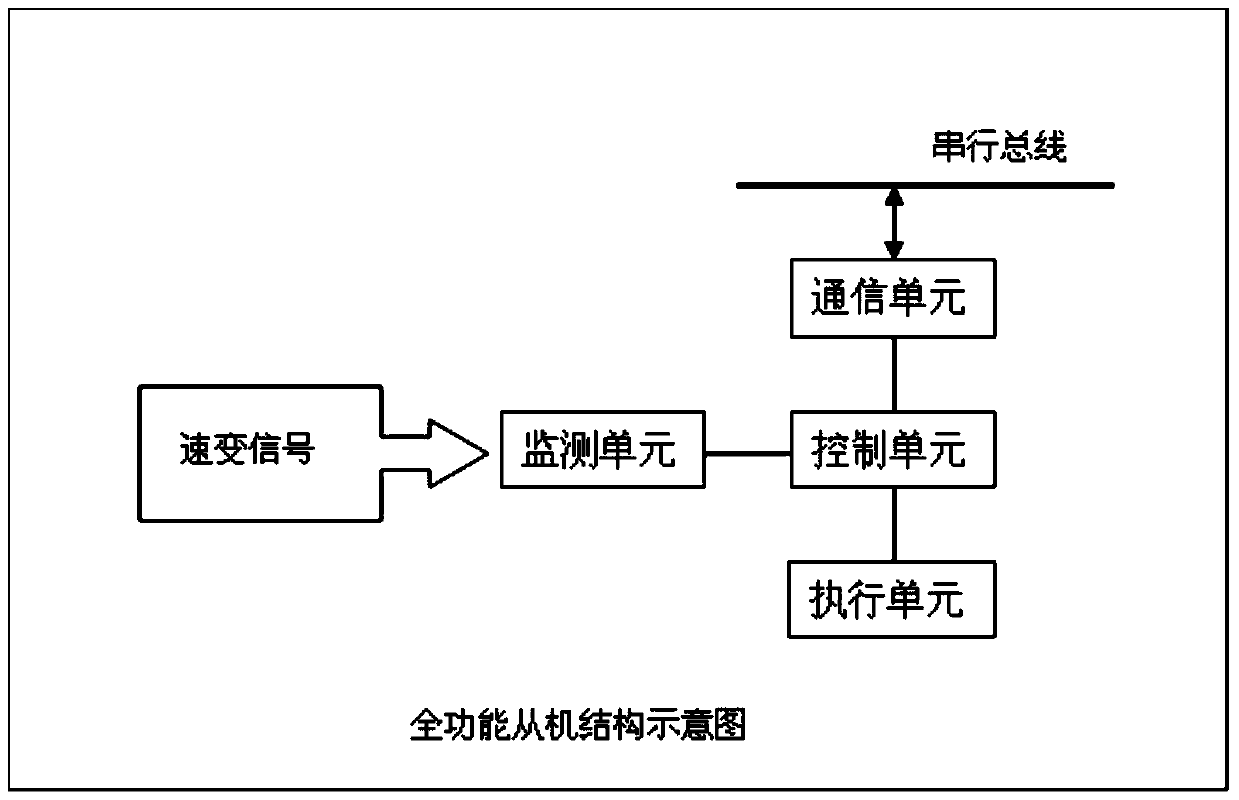

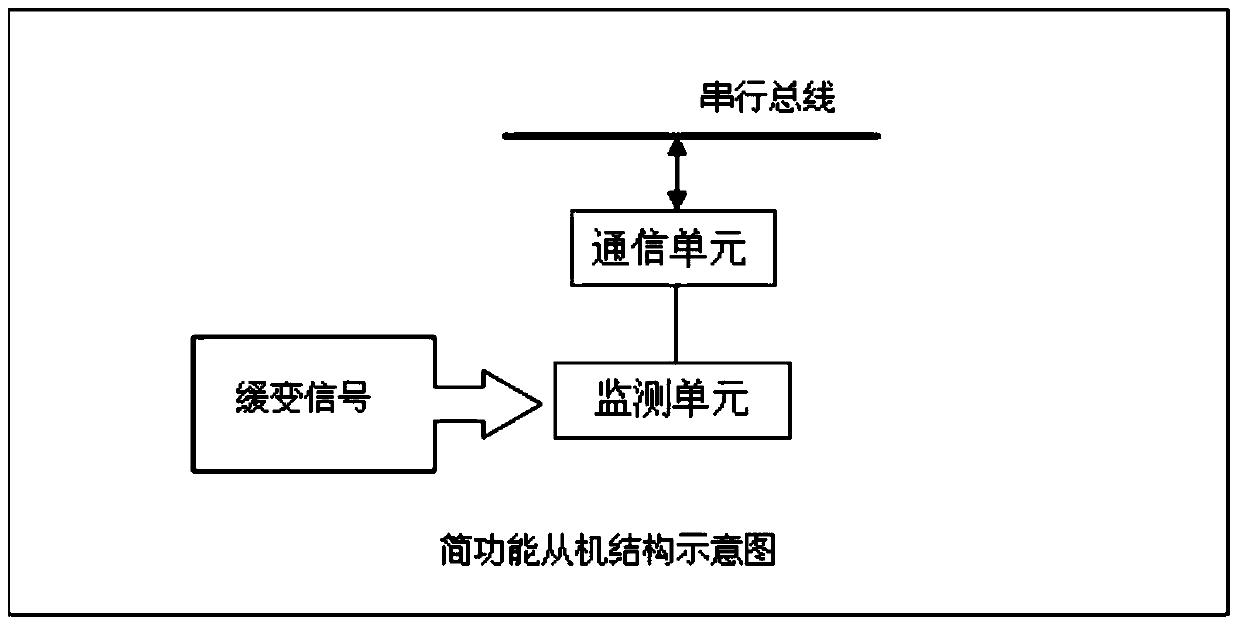

[0027] The system consists of a monitoring host, a full-featured slave and a number of simple-function slaves. The full-function slave has monitoring and interlock control functions, and the simple-function slave only has the monitoring function. The slaves are bound and set to form a functional cluster. The monitoring host is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com