Generation Method of Spliced Planar Spiral Inductor

A planar spiral and splicing technology, applied in the direction of inductors, circuits, electrical components, etc., can solve the problems that cannot fully meet the design needs, have no inductance model, single variety, etc., and achieve fast and effective generation methods, clear structures, and parameter settings. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

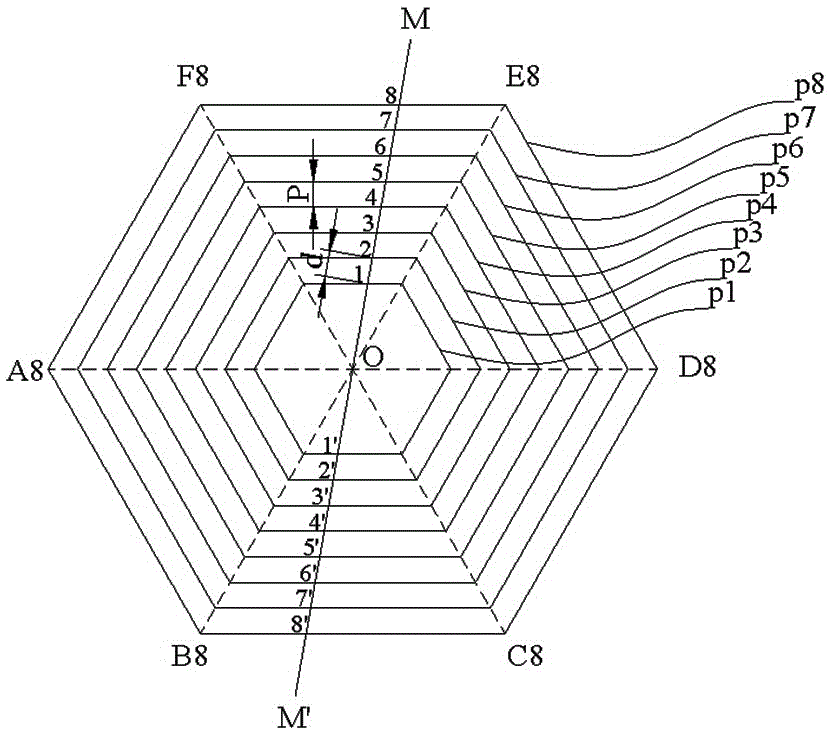

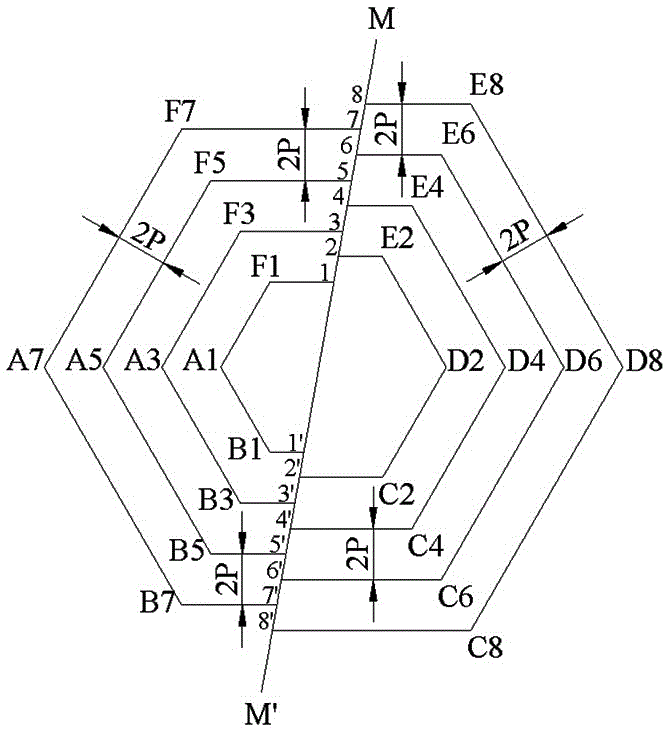

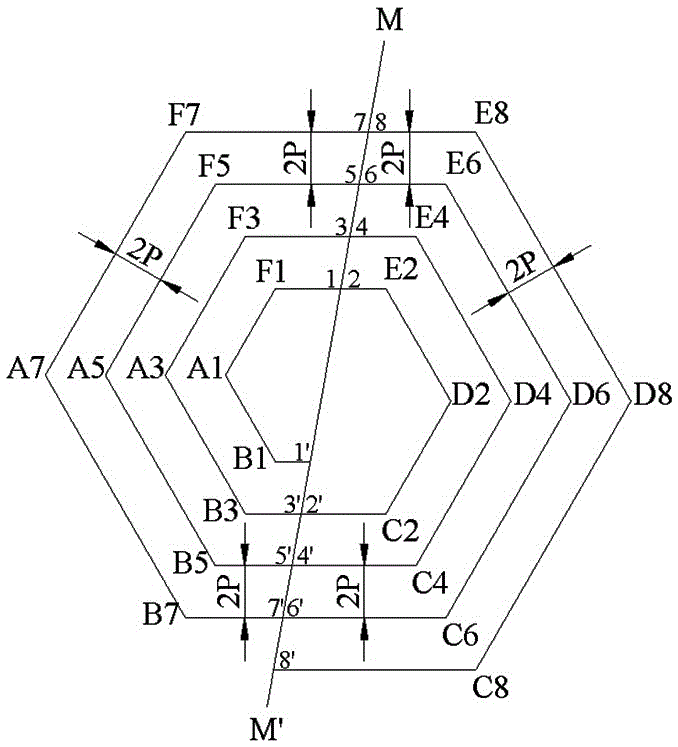

[0027] Such as figure 1 As shown, a group of concentric regular hexagons is generated, the center point is O, the sides of the regular hexagons are correspondingly parallel, and the distance between the corresponding sides of adjacent regular hexagons is a fixed value P. The regular hexagons are numbered as p1, p2, ... p8 from inside to outside. The vertices of p1 are A1, B1, C1, D1, E1, F1; the vertices of p2 are A2, B2, C2, D2, E2, F2; and so on, the vertices of p8 are A8, B8, C8, D8 , E8, F8.

[0028] The straight line MM' intersects [E1, F1] at point 1, [E1, F1] refers to the line segment whose two end points are E1, F1, and so on, intersects [E2, F2] at point 2, ..., intersects [E8, F8] at point 8; straight line MM' intersects [B1, C1] at point 1', intersects [B2, C2] at point 2', ..., intersects [B8, C8] at point 8'. Due to the structural characteristics of regular hexagons, side [E1, F1] is parallel to side [B1, C1], side [E2, F2] is parallel to side [B2, C2], and so...

Embodiment 2

[0034] Such as Figure 5 As shown, a group of concentric regular pentagons is generated, the center point is O, the sides of the regular pentagons are correspondingly parallel, and the distance between the corresponding sides of adjacent regular pentagons is a fixed value P. The regular pentagons are numbered p1, p2, ... p8 from the inside to the outside. The vertices of p1 are A1, B1, C1, D1, E1; the vertices of p2 are A2, B2, C2, D2, E2; and so on, the vertices of p8 are A8, B8, C8, D8, E8.

[0035]Said set of concentric regular pentagons is symmetrical about the axis of symmetry NN'. Due to the regular pentagon structure, any two sides are not parallel to each other, so it is impossible to make a straight line intersect two sets of parallel sides as in the first embodiment. In this embodiment, the straight line MM' can be made perpendicular to the axis of symmetry NN'.

[0036] Line MM' intersects [D1, E1] at point 1, intersects [D2, E2] at point 2, ..., intersects [D8, ...

Embodiment 3

[0041] Such as Figure 8 As shown, the octagon p1 is first generated, and the vertices are A1, B1, C1, D1, E1, F1, G1, and H1 respectively. The interior angles of the octagon p1 are all 135°, and the octagon p1 is symmetrical about the straight line NN' and symmetrical about the straight line MM'. For other sizes see Figure 8 , the unit is μm.

[0042] Such as Figure 9 As shown, each side of p1 is equally spaced and extended to meet each other to form a group of similar polygons, and the equal space value is P=3μm. Line MM' vertically intersects [G1, F1] at point 1, perpendicularly intersects [G2, F2] at point 2, ..., perpendicularly intersects [G7, E7] at point 7; straight line MM' perpendicularly intersects [B1, C1] at point 1', perpendicular to [B2, C2] at point 2', ..., perpendicular to [B7, C7] at point 7'. It is easy to obtain that the line segment length d=P=3μm obtained by cutting the straight line M M' on the polygon group.

[0043] With reference to Example 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com