Electronic component packaging structure and electronic device

An electronic component and packaging structure technology, applied in the field of electronic component packaging structure and electronic equipment, can solve problems such as poor high-frequency EMI shielding effect, and achieve the effect of improving EMI shielding effect and reducing radiated EMI.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

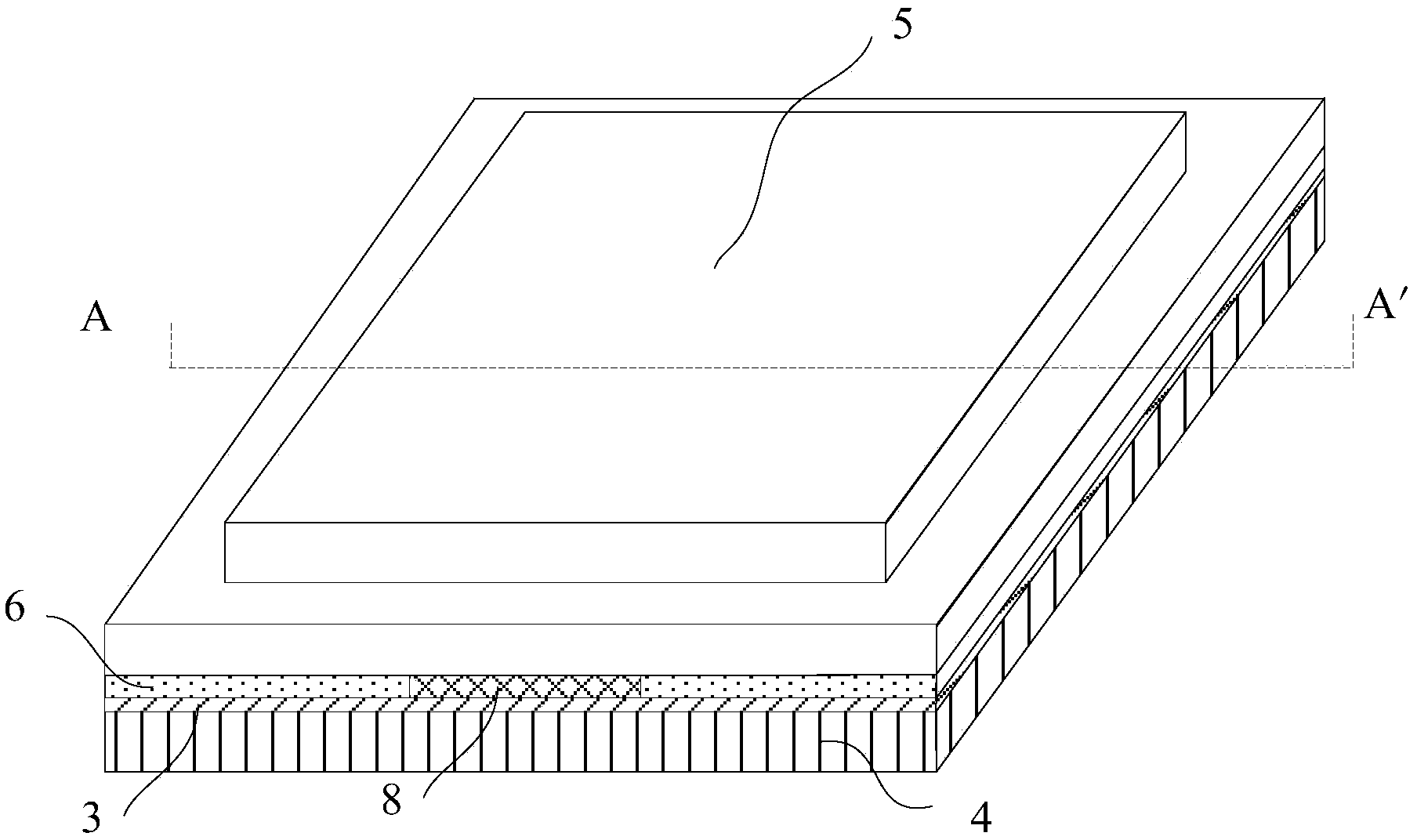

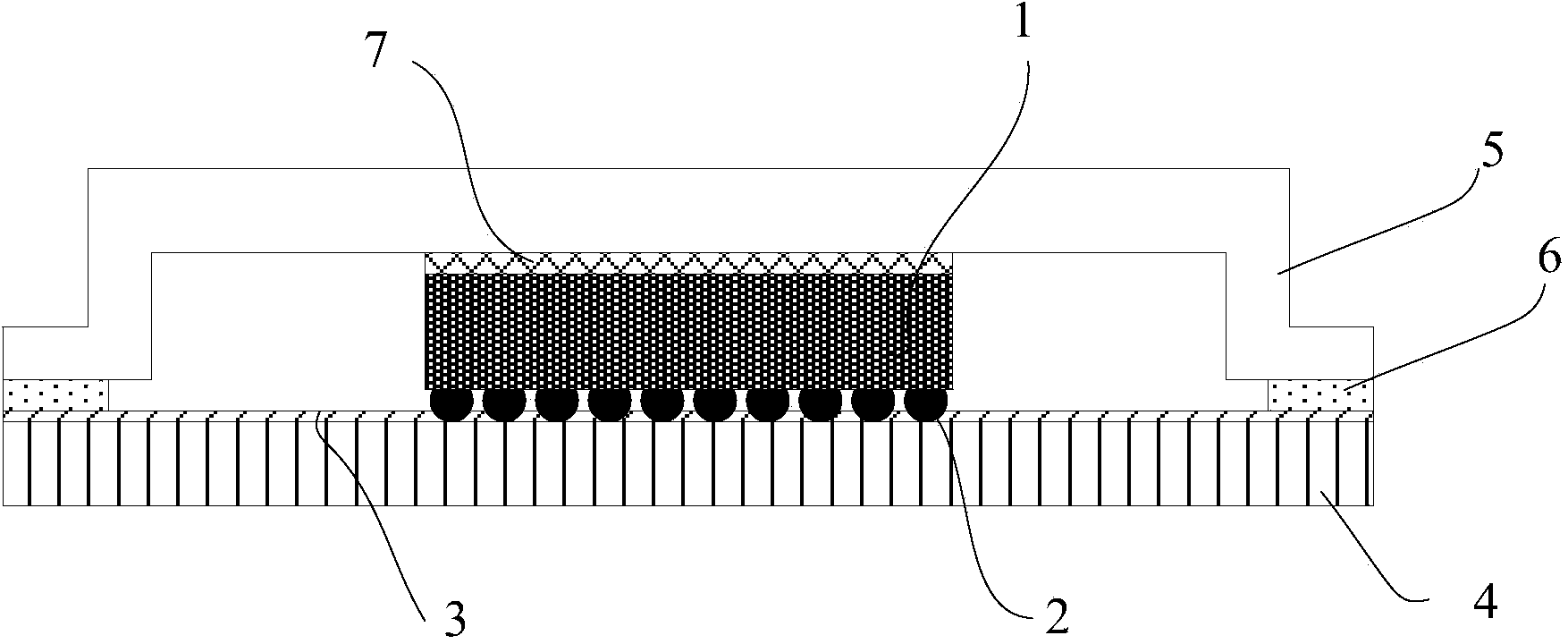

[0044] Figure 4 Shown is a top view of an electronic component packaging structure with EMI shielding effect provided by an embodiment of the present invention, Figure 5 Shown is provided by the embodiment of the present invention Figure 4 The schematic diagram of the cross-sectional structure of the packaging structure of the electronic component shown in the A-A' direction. combine Figure 4 with Figure 5 It can be seen that the electronic component packaging structure provided by the embodiment of the present invention includes an electronic component (chip or discrete component) 1, a circuit pin 2, a solder resist layer 3, a substrate 4, a conductive casing 5, and Between the non-conductive glue 6, and the thermally conductive glue 7, where:

[0045]The substrate 4 has a set attachment area S for attaching electronic components. The size and shape of the attachment area S can be set according to the size and shape of the electronic components actually packaged. 6 ...

Embodiment 2

[0061] In the embodiment of the present invention, chips can be attached in the attachment area set on the substrate 4 , and other discrete components, such as capacitors, resistors, transistors and other electronic components, can also be arranged.

[0062] The electronic component packaging structure provided in the embodiment of the present invention, the electronic component packaging structure when attaching chips, discrete components, and chips and discrete components to the attachment area set on the substrate 4 is basically the same as the above-mentioned embodiment, that is: non-conductive The adhesive has a high DK value. The coating area of the high DK non-conductive adhesive on the substrate should be as large as possible, and it should be coated on the entire area of the surface of the substrate facing the conductive shell except the attachment area. The thickness should be thin and the DK should be high. The removal of the solder mask layer at the non-conducti...

Embodiment 3

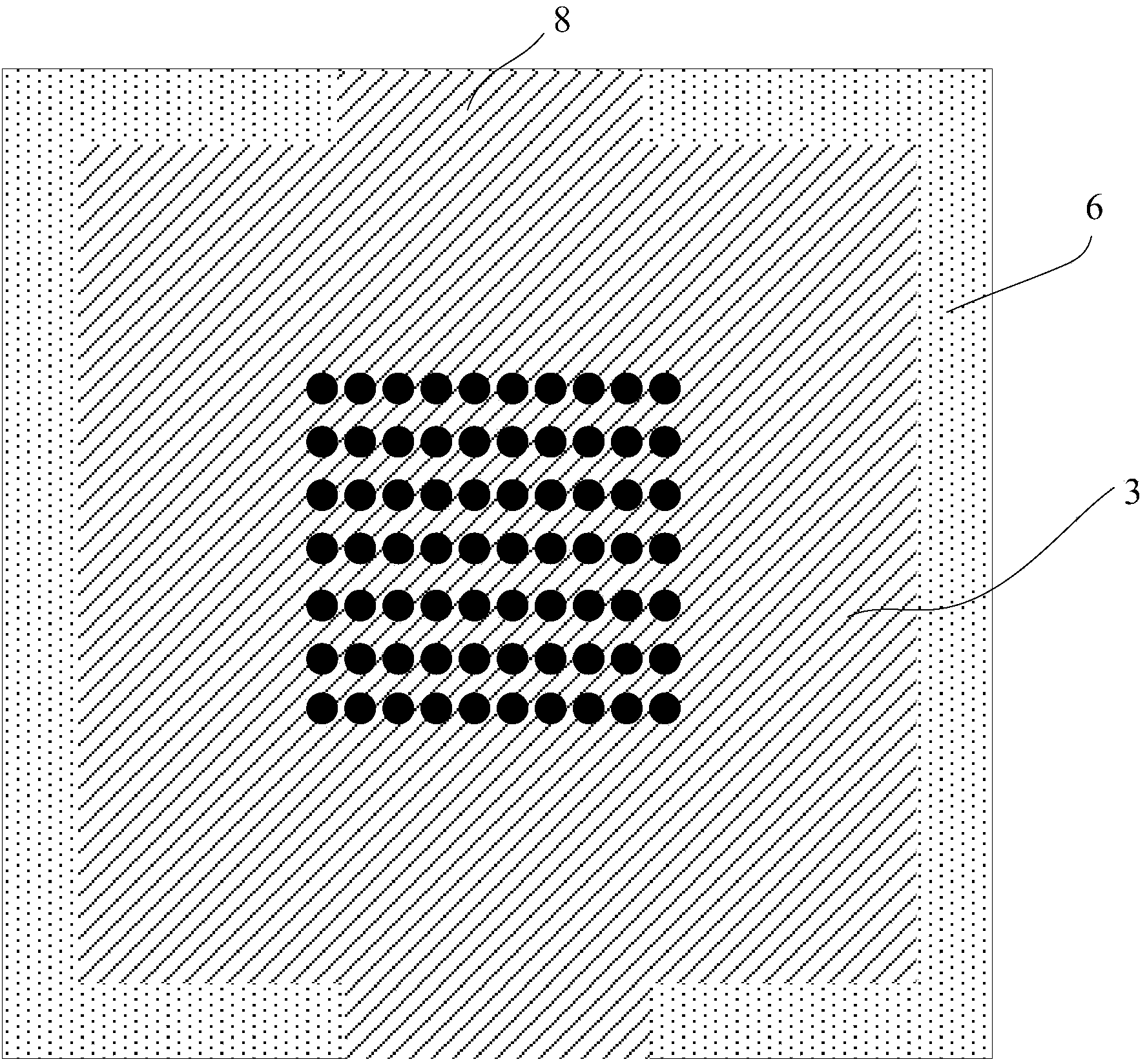

[0069] In the embodiment of the present invention, in order to ensure the reliability of the process, the vent hole 8 can be reserved on the high DK non-conductive adhesive, that is, the vent hole 8 is set on the high DK non-conductive adhesive, refer to Figure 10 with Figure 11 shown. Figure 10 Shown is a top view of the electronic component packaging structure in which the vent holes are arranged on the high DK non-conductive glue in the embodiment of the present invention, Figure 11 shown as Figure 10 The schematic diagram of the cross-sectional structure of the electronic component packaging structure shown in the A-A' direction.

[0070] Specifically, the difference between the electronic component packaging structure involved in the embodiment of the present invention and the above-mentioned embodiment lies in the setting position of the vent hole. The embodiment of the present invention will only describe the difference below, and the other same or similar points...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com