Coating technological method and coating system of motorboat

A coating process and motorboat technology, applied in the direction of the surface coating liquid device, coating, spraying device, etc., to achieve the effect of smooth and smooth paint layer, full paint layer and clear color separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

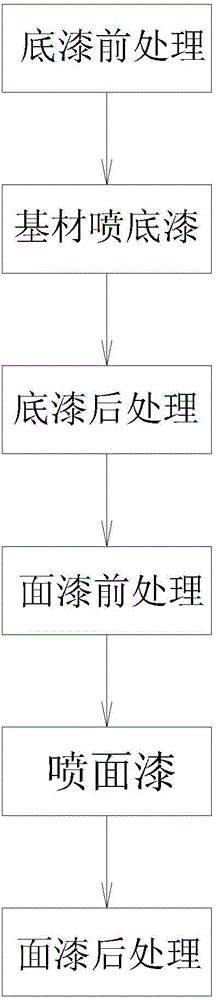

[0061] See attached figure 1 with 2 , a kind of coating process method of motor boat provided by the present invention comprises:

[0062] Step 1: Carry out primer pretreatment to the SMC substrate; the primer pretreatment includes the following processes: SMC substrate grinding, cleaning, drying, pasting covering materials, drying, cooling, static removal, and dust removal; SMC substrate The grinding process is carried out in a dust-free grinding room. First, use a 60#~100# pneumatic grinder to grind, and then use a 360#~400# water grinder; the cleaning process is tap water; the drying process uses compressed air to dry; the covering material process is pasted Use masking paper and masking paper to cover the parts not to be sprayed; the temperature in the drying process is controlled at 80°C to 100°C, and the holding time is 10 minutes; the cooling process uses compressed air to cool down; the electrostatic gun is used to remove static electricity; the dust removal process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com