PVC expanded plastic composite board and production method and application thereof

A technology of foamed plastics and PVC materials, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as poor adhesion of composite boards, bubble burst compression, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] step 1

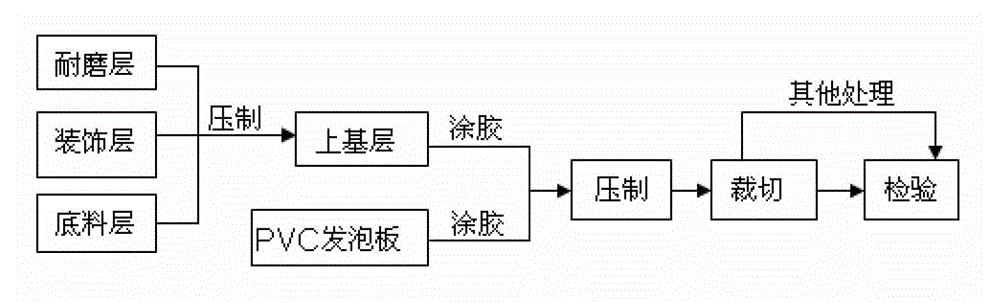

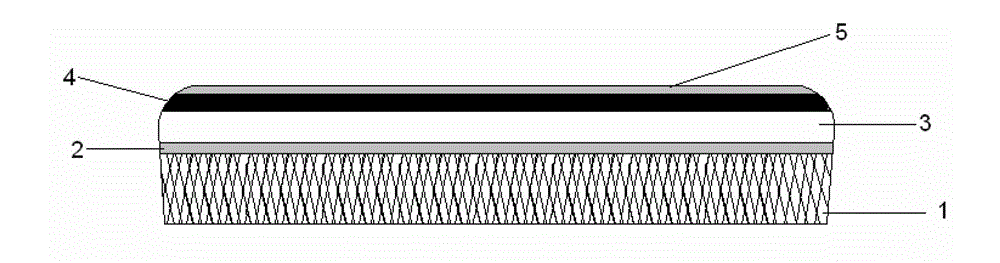

[0077] refer to figure 1 and figure 2 .

[0078] A primer layer 3, a decorative layer 4 and a wear-resistant layer 5 are provided, and the primer layer 3, the decorative layer 4 and the wear-resistant layer 5 are stacked from bottom to top, and then press-molded to obtain an upper base layer. Compression can be performed using methods known in the field of materials engineering. Among them, the bottom material layer is PVC board with a thickness of 1mm; the thickness of the decorative layer is 0.3mm, the thickness of the wear-resistant layer is 0.2mm, and the total thickness of the upper base layer is 1.5mm.

[0079] Provide PVC foam board as foam layer 1, thickness is 4mm, the production method of PVC foam board has been described in detail in the prior art, those skilled in the art can prepare according to the record of prior art, according to weight percentage , the preparation of the present embodiment PVC foam board component is:

[0080] PVC 70%; ...

Embodiment 2

[0101] step 1

[0102] A primer layer 3, a decorative layer 4 and a wear-resistant layer 5 are provided, and the primer layer 3, the decorative layer 4 and the wear-resistant layer 5 are stacked from bottom to top, and then press-molded to obtain an upper base layer. Among them, the bottom material layer is PE board with a thickness of 1mm, and the total thickness of the upper base layer is 1.5mm.

[0103] A PVC foam board is provided as the foam layer 1 with a thickness of 4 mm. According to the percentage by weight, the PVC foam board components of this embodiment are prepared as follows:

[0104] PVC 50%;

[0105] Foaming agent 2%;

[0106] Foam regulator 6%;

[0107] Stabilizer 3%;

[0108] Plasticizer 8%;

[0109] Lubricant 1%;

[0110] Heavy calcium 10%;

[0111] Toughener 6%;

[0112] Flame retardant 8%;

[0113] Antibacterial and antifungal agent 3%;

[0114] Other available additives in this field 3%.

[0115] step 2

[0116] Glue is applied to the upp...

Embodiment 3

[0124] step 1

[0125] A primer layer 3, a decorative layer 4 and a wear-resistant layer 5 are provided, and the primer layer 3, the decorative layer 4 and the wear-resistant layer 5 are stacked from bottom to top, and then press-molded to obtain an upper base layer.

[0126] Among them, the bottom material layer is PE board, and the total thickness of the upper base layer is 0.7mm.

[0127] A PVC foam board is provided as the foam layer 1 with a thickness of 4 mm. According to the percentage by weight, the PVC foam board components of this embodiment are prepared as follows:

[0128] PVC 80%;

[0129] Foaming agent 3%;

[0130] Foam regulator 5%;

[0131] Stabilizer 2%;

[0132] Lubricant 1%;

[0133] Toughener 5%;

[0134] Flame retardant 3%;

[0135] Antimicrobial Antifungal Agent 1%.

[0136] step 2

[0137] Glue is applied to the upper surface of the PVC foam layer 1, and glue is applied to the lower surface of the primer layer 3. The PVC foam layer 1 is atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com