Pile foundation construction mud treatment system and mud treatment process

A construction mud and treatment system technology, applied in the direction of water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problem of increased mud disposal costs, on-site mud and water overflow, and mud is difficult to discharge and other problems, to achieve the effect of accelerating precipitation, reducing the dosage, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

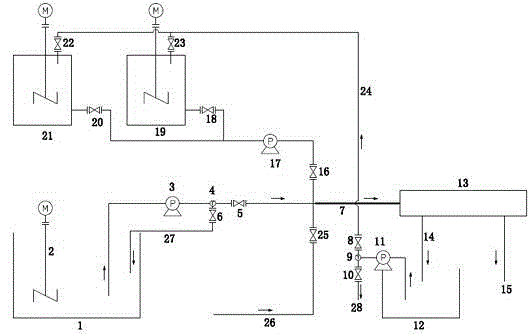

[0031] like figure 1 As shown, a pile foundation construction mud treatment system of the present invention includes a mud feeding system, a flocculant mixing system, a cleaning system, a mud-water separation system and a water recovery system;

[0032] The mud feeding system includes a mud pool 1, a stirring device 2 is arranged in the mud pool 1, and the stirring device 2 includes a mixer and an agitator, and the mud pool 1 is sequentially connected with the slurry pump 3 and the first three-way pipe 4 through the pipeline connection, a slurry return pipe 27 is set between the first three-way pipe 4 and the mud pool 1, and part of the mud forms a circulation between the mud pool 1, the slurry pump 3, the first three-way pipe 4 and the slurry return pipe 27; The first valve 5 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com