Foamed ceramic wall insulation material and preparation method thereof

A technology of thermal insulation materials and foam ceramics, applied in the field of thermal insulation materials, can solve the problems of low reprocessing utilization rate, poor thermal insulation and energy saving effect, serious environmental pollution, etc., and achieve excellent thermal shock resistance, cost reduction, and low heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

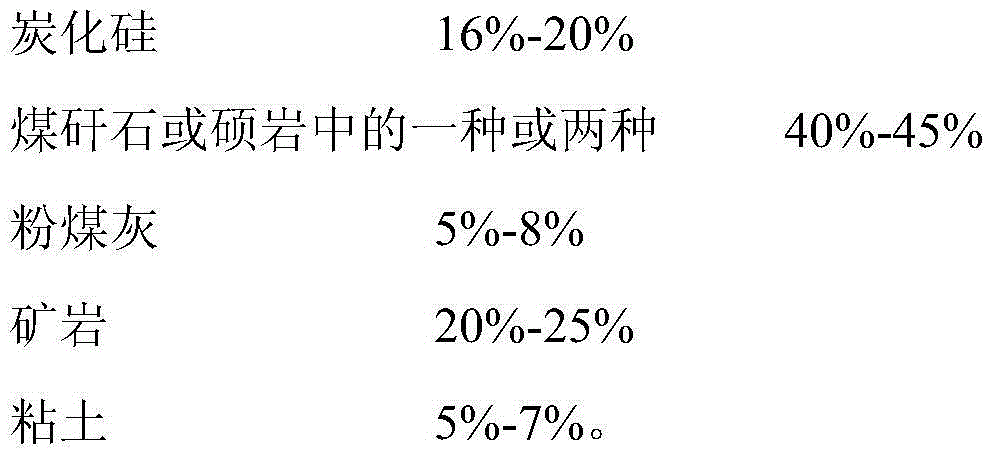

[0020] A foam ceramic wall insulation material is made of the following raw materials in weight fraction:

[0021]

[0022] Among them: the particle size of coal gangue and Shuoyan is 80 mesh, the particle size of fly ash is 120 mesh, the particle size of ore rock is 80 mesh, and the particle size of clay is 120 mesh.

[0023] The preparation method comprises the following steps:

[0024] All raw materials are pulverized separately, mixed in proportion, stirred by a mixer, fed and fired, the firing temperature is 1150°C, and the firing time is 48 hours.

[0025] The product performance test result that embodiment 1 prepares is as follows: Bulk density is 270kg / m 3 , thermal conductivity 0.095W / (M·K), tensile strength 0.35MPa, water absorption 7%.

Embodiment 2

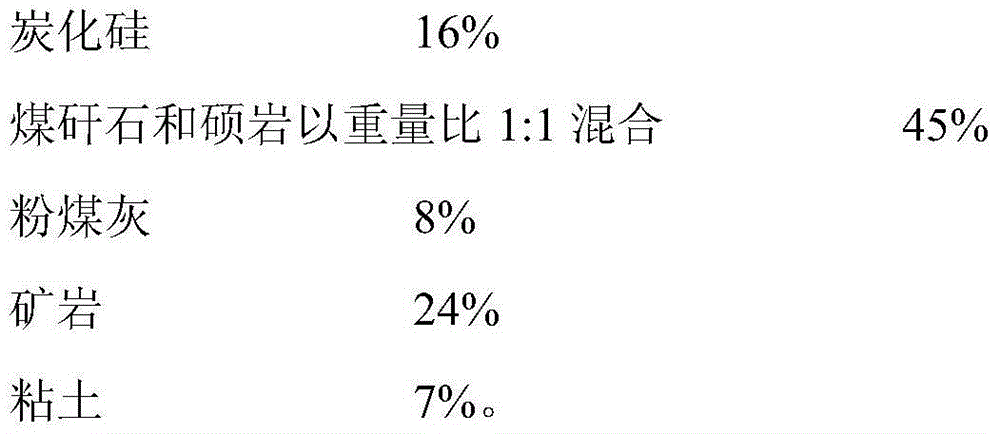

[0027] A foam ceramic wall insulation material is made of the following raw materials in weight fraction:

[0028]

[0029] Among them: the particle size of coal gangue is 120 mesh, the particle size of fly ash is 100 mesh, the particle size of ore rock is 100 mesh, and the particle size of clay is 80 mesh.

[0030] The preparation method comprises the following steps:

[0031] All raw materials are pulverized separately, mixed in proportion, stirred by a mixer, fed and fired, the firing temperature is 1120°C, and the firing time is 52 hours.

[0032] The product performance test result that embodiment 2 prepares is as follows: Bulk density is 250kg / m 3 , thermal conductivity 0.092W / (M·K), tensile strength 0.29MPa, water absorption 6%.

Embodiment 3

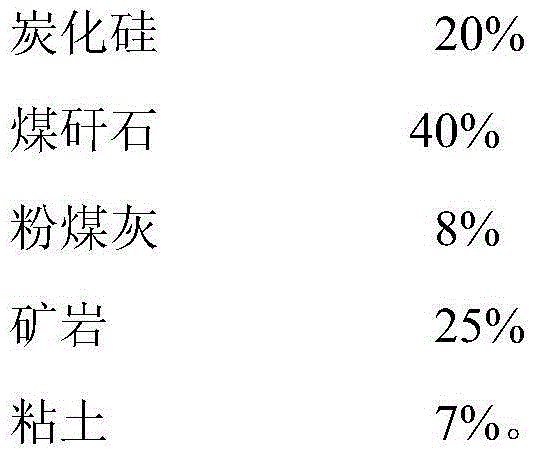

[0034] A foam ceramic wall insulation material is made of the following raw materials in weight fraction:

[0035]

[0036] Among them: the particle size of Shuoyan is 100 mesh, the particle size of fly ash is 80 mesh, the particle size of ore rock is 120 mesh, and the particle size of clay is 100 mesh.

[0037] The preparation method comprises the following steps:

[0038] All the raw materials are pulverized separately, mixed in proportion, stirred by a mixer, fed and fired, the firing temperature is 1140°C, and the firing time is 50 hours.

[0039] The product performance test result that embodiment 3 prepares is as follows: Bulk density is 280kg / m 3 , thermal conductivity 0.090W / (M·K), tensile strength 0.32MPa, water absorption 6.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com