Fermentation tank capable of defoaming by using ultrasonic waves

A fermenter, ultrasonic technology, applied in specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, method of stress-stimulated microbial growth, etc. Fermentation foam and removal of air distributor dirt improvement and other issues to achieve the effect of reducing defoaming costs, reducing the chance of bacterial contamination, and eliminating foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

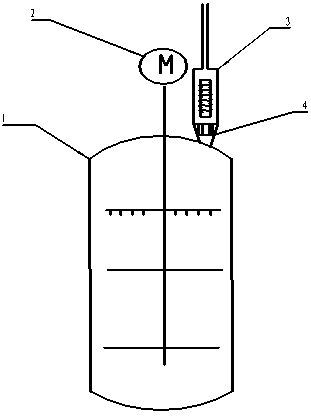

[0032] Example 2 A fermentation tank using ultrasonic defoaming, the structure can still refer to the attached figure 1 , But different from Example 1, the volume of the fermenter is 350m 3 , The volume of cyclone separator 3 is 30m 3 , The power of the stirring motor 2 is 420kW.

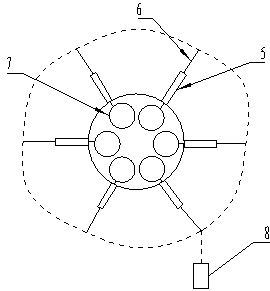

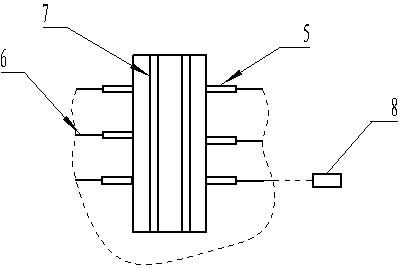

[0033] Three ultrasonic generators 4 are installed at the bottom of the fermenter cyclone 3. The defoaming reactor 7 and the transducer 5 are connected by a reducing rod and a flange. Five fixing nuts are arranged on the periphery of the flange. The connection method is screw connection. The transducer 5 is connected in series with a special high-frequency wire 6 and Connect to the controller 8 and the power supply.

[0034] Example 3 A fermentation tank using ultrasonic defoaming, the structure can still refer to the attached figure 1 , But different from Example 1, the volume of the fermentation tank is 500m 3 , The volume of cyclone separator 3 is 35m 3 , The power of the stirring motor 2 is 750kW. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com