Selective laser melting (SLM) vacuum protection device

A technology of laser melting and vacuum protection, which is applied in the direction of coating, metal material coating process, energy efficiency improvement, etc., can solve the problems of increasing the oxygen content of metal parts, reducing the mechanical properties of metal parts, and affecting the performance of parts, etc., to achieve The effect of convenient operation, high degree of automation and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

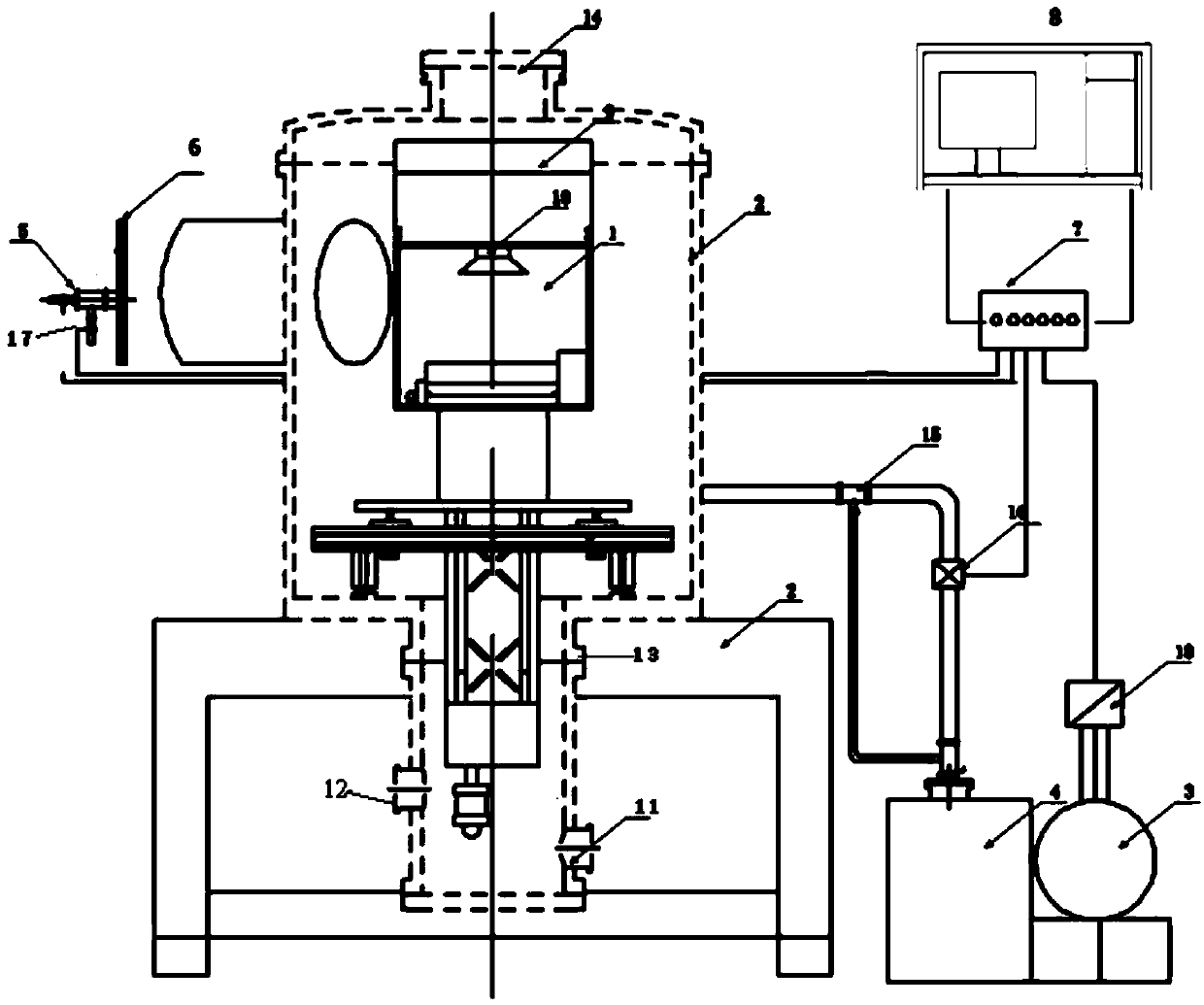

[0009] The main structure of this embodiment includes SLM forming working mechanism 1, sealed cabin 2, mechanical pump 3, Roots pump 4, inert gas valve 5, integrated flange 6, central control system 7, upper computer 8, scanning array mirror system 9. Laser lens 10, oxygen sensor 11, pressure sensor 12, temperature sensor 13, alarm indicator light 14, self-adaptive pipeline 15, pipeline valve 16, intake solenoid valve 17 and vacuum solenoid valve 18; stainless steel vacuum structure seal There is an SLM forming working mechanism 1 inside the cabin 2, and the sealed cabin 2 communicates with the vacuum pump group composed of the Roots pump 4 and the mechanical pump 3 through the adaptive pipeline 15. The adaptive pipeline 15 is provided with a pipeline valve 16, and the mechanical pump 3 The upper end is provided with a vacuum electromagnetic valve 18; the inert gas valve 5 is connected with the central control system 7; one side of the inert gas valve 5 is connected with an int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com