Reinforced concrete structure hollow thin wall pier type steel frame column and construction method thereof

A hollow thin-walled, steel-concrete structure technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of high input cost, high labor cost, affecting construction period, etc., and achieve low construction cost, short construction period, and improved The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

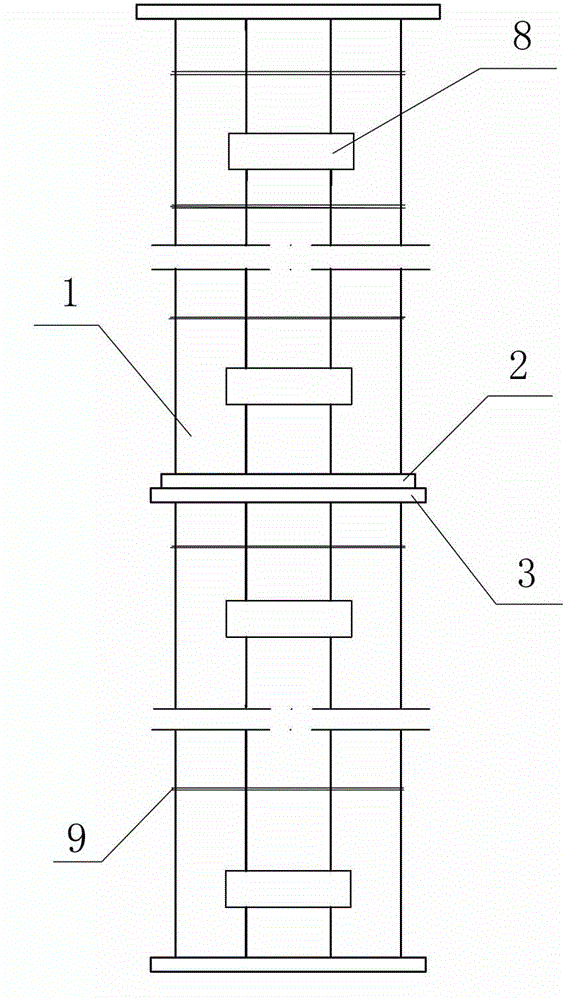

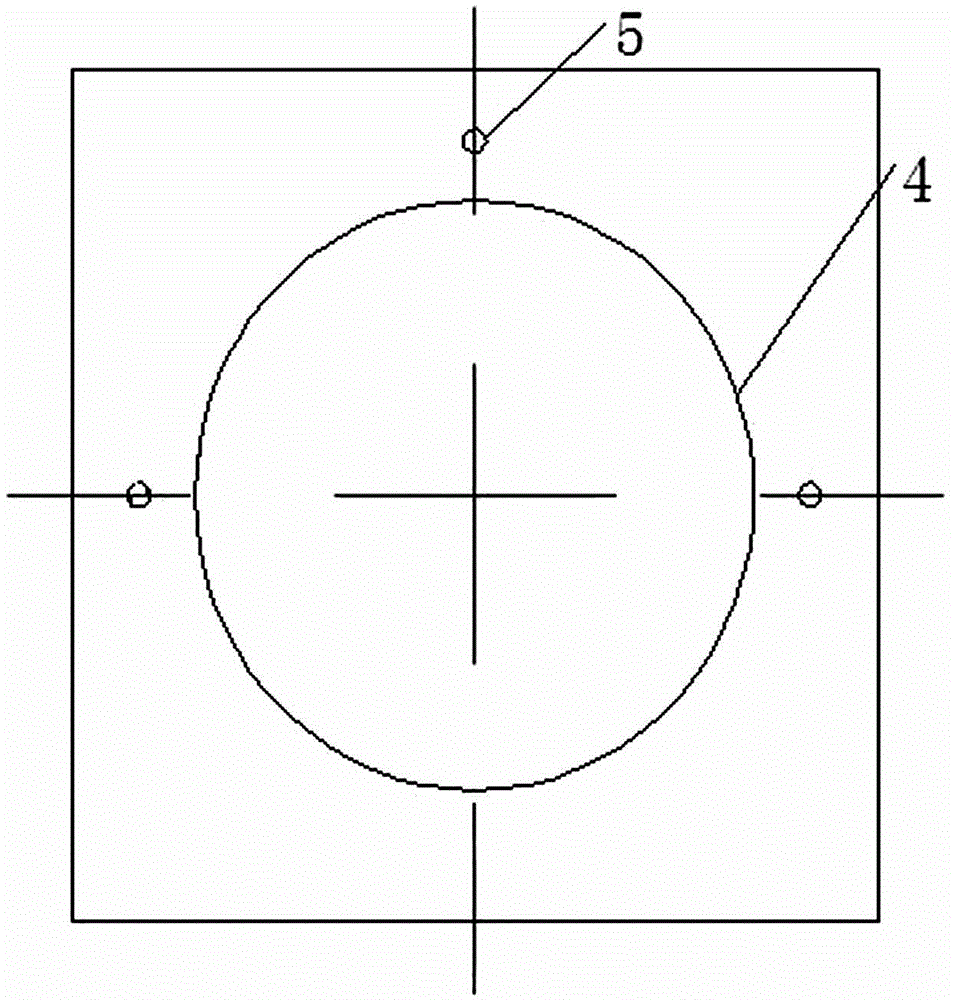

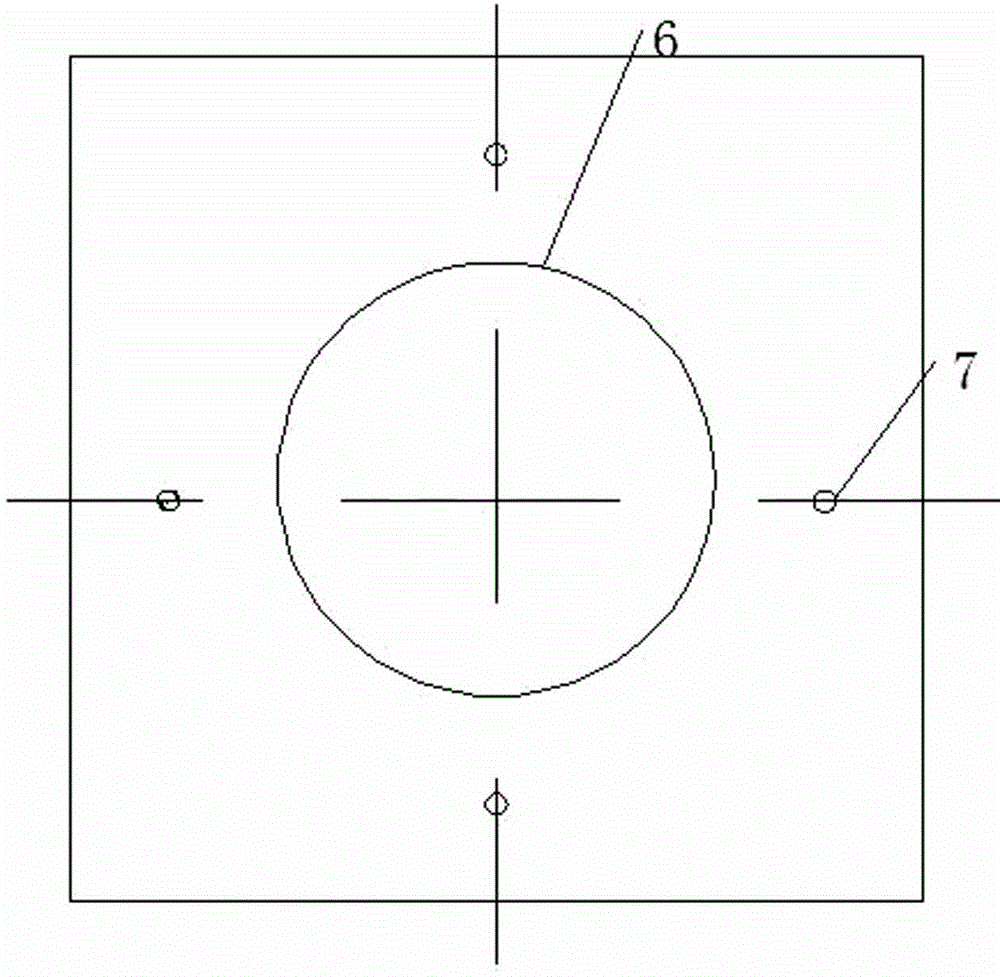

[0037] Such as figure 1 As shown, a steel-concrete structure hollow thin-walled pier-shaped steel skeleton column, its main body has four angle steels 1 arranged at the four corners of the column and patch plates 8 welded between two adjacent angle steels at intervals, the upper ends of the four angle steels are connected with The upper positioning steel plate 3 is welded, and the lower end is welded with the lower positioning steel plate 2. It is characterized in that the lower positioning steel plate 2 and the upper positioning steel plate 3 are rectangular, and a central hole is opened at the geometric center of the positioning steel plate. Four symmetrical positioning holes are arranged on the top, and the supporting positioning holes also include reinforcing bar positioning pins that can be inserted in the positioning holes, and stirrups 9 are also welded at intervals around the four angle steels 1 . The upper positioning steel plate 3 and the lower positioning steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com