Artificial microscopic simulation physical model and manufacturing method thereof

A technology of microscopic simulation and physical model, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of large volume, opaque matrix, difficult cutting, etc., and achieve high clarity and light transmission Good, good core repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

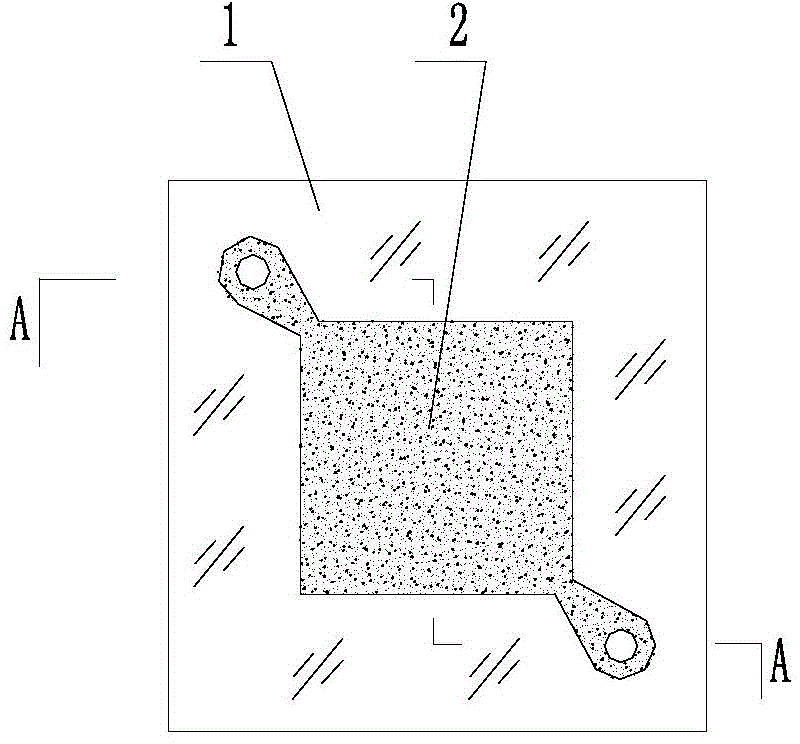

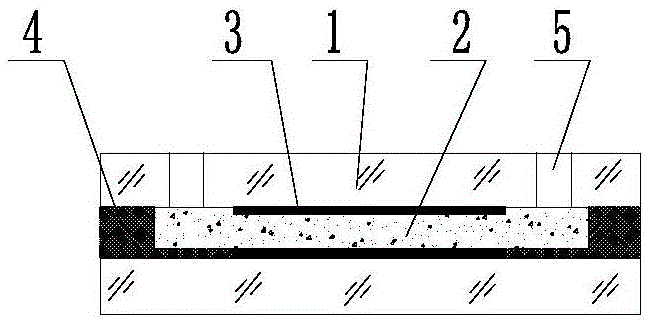

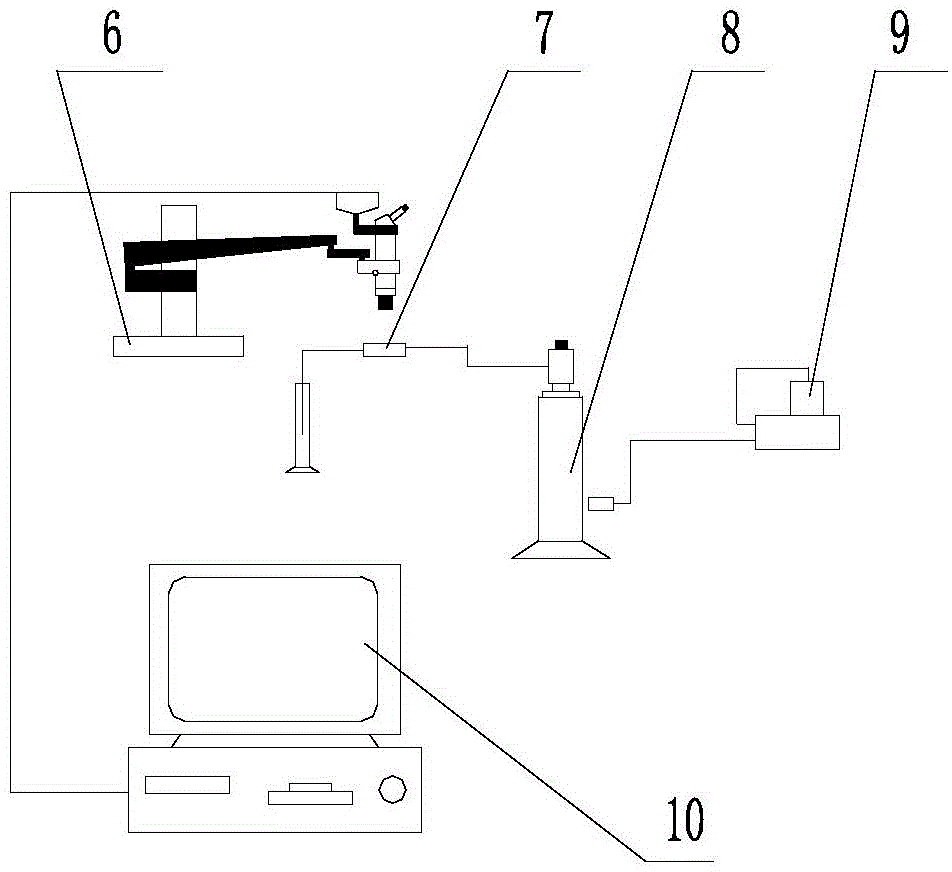

[0029] figure 1 Shown is an artificial microscopic simulation physical model, including two transparent plexiglass plates 1, the relative inner middle areas of the above two transparent plexiglass plates 1 are coated with ultraviolet light curing adhesive 3, and quartz sand is sandwiched between the two ultraviolet light curing adhesive layers Layer 2, the quartz sand layer 2 is surrounded by a sealant 4, which is sealed with two transparent organic glass plates. The above-mentioned quartz sand layer 2 is composed of a large particle size quartz sand layer and a small particle size quartz sand layer, and corresponds to the obliquely diagonally drilled holes 5 on the transparent organic glass plate on the small particle size quartz sand side. The specific structure is as follows: figure 1 and figure 2 shown.

[0030] The specific manufacturing method of the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap