Device and method for identifying laser damages to optical film

A technology of optical thin films and identification devices, which is applied in measuring devices, scientific instruments, and material analysis through electromagnetic means, etc., can solve problems such as plasma flash and atmospheric breakdown, and achieve high discrimination accuracy, fast discrimination speed, and small interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

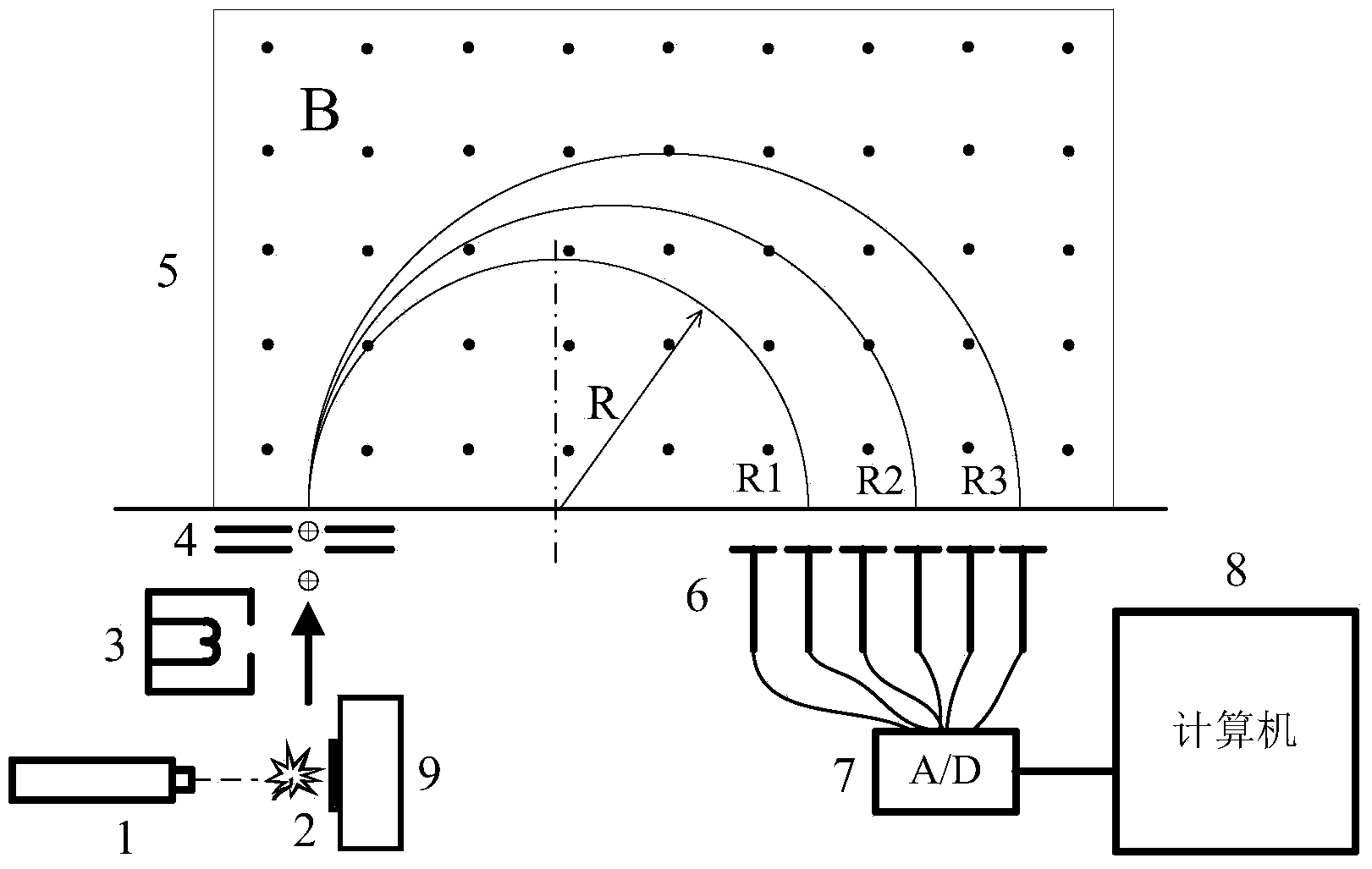

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0027] see figure 1 The identification device for laser damage to optical thin films of the present invention includes a laser 1 and a test sample 2. The laser 1 is a high-energy laser that can damage the film on the surface of the test sample 2, and the wavelength of the laser is 1064nm, the pulse width is 10ns, and the maximum single pulse The energy is 400mJ; the test sample 2 is installed on the test sample table 9, which is a two-dimensional mobile platform controlled by a stepping motor; the laser 1 is facing the surface to be tested of the test sample 2, and one side of the test sample table 9 An accelerating electrode 4 for accelerating the particles sputtered out of the sample by laser irradiation and forming a collimated particle beam is provided, and an electron source 3 for increasing the ion content is also provided between the test sample stage 9 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com