Rolling bearing remaining life prediction method based on feature fusion and particle filtering

A particle filter and rolling bearing technology, which is applied in prediction, data processing applications, calculations, etc., can solve the problems of limiting the application of particle filter methods, poor application effects, and great changes in initial parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

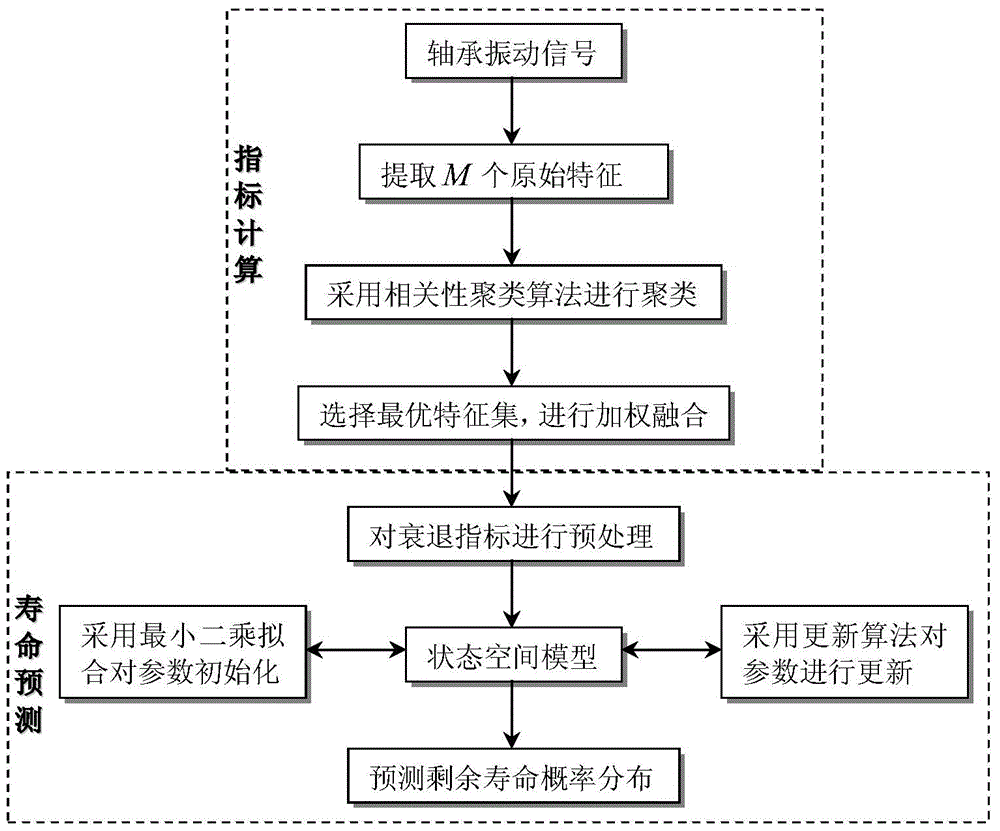

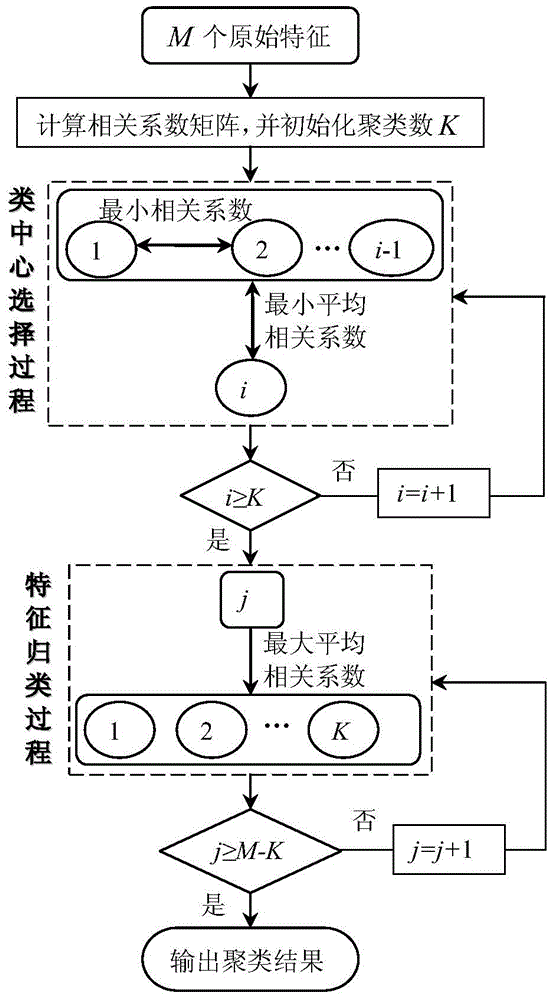

Method used

Image

Examples

Embodiment

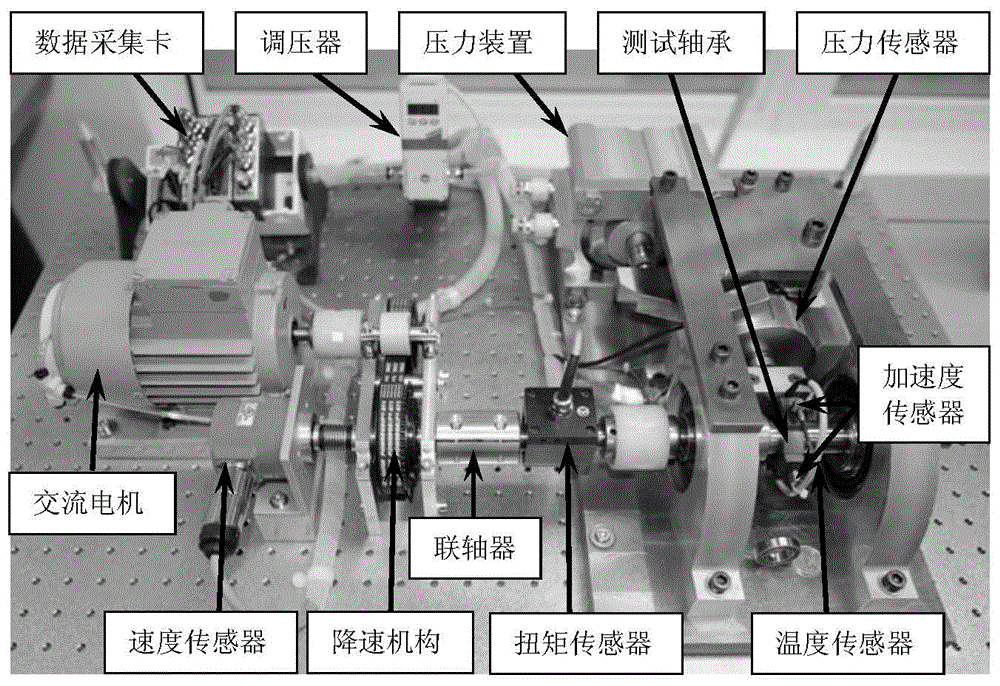

[0075] Embodiment: The correctness of the method of the present invention is verified by using the experimental data of accelerated life of rolling bearings collected on the PRONOSTIA test bench.

[0076] PRONOSTIA test bench such as image 3 As shown, the test bench is specially designed for the verification of rolling bearing fault diagnosis and trend prediction methods. The test bench consists of three parts: transmission mechanism, loading part and data acquisition system. The rotational speed of the experimental bearing is 1800rpm, and the load is 4000N. The sampling frequency is 25.6kHz, the data length is 2560, the duration of each sampling is 0.1s, and the sampling interval is 10s, and the acceleration sensors installed in the horizontal and vertical directions of the bearing seat are sampled simultaneously. Bearings start normally until they fail completely. The experimental data includes two sets of bearings, a training bearing and a test bearing, and the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com