Semiconductor package and method for manufacturing same

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor device, semiconductor/solid-state device components, etc., can solve the problem of high wettability, reduced wiring density, and cannot fully meet the requirements of thinning And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

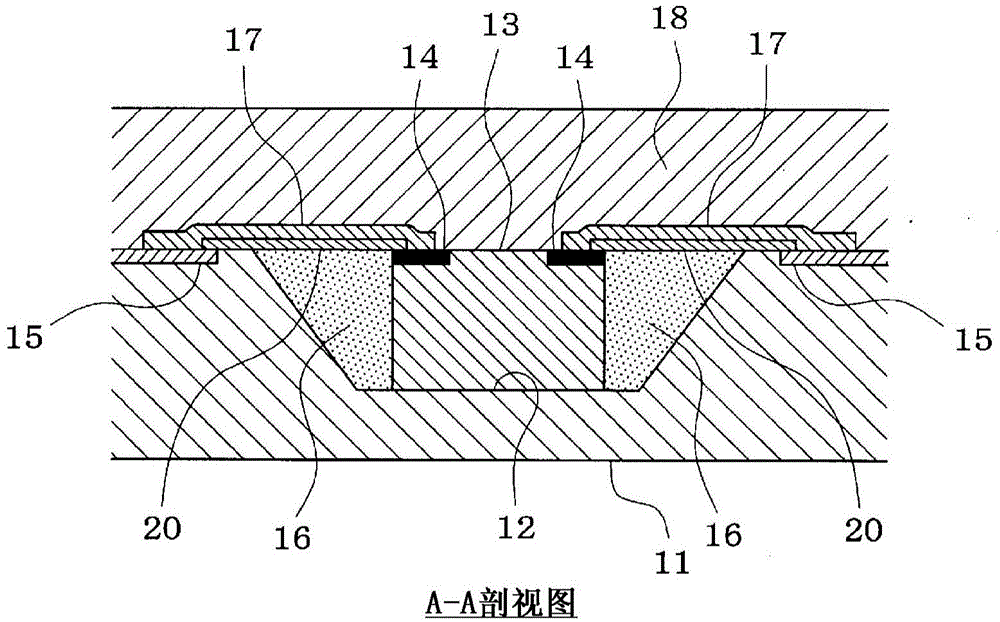

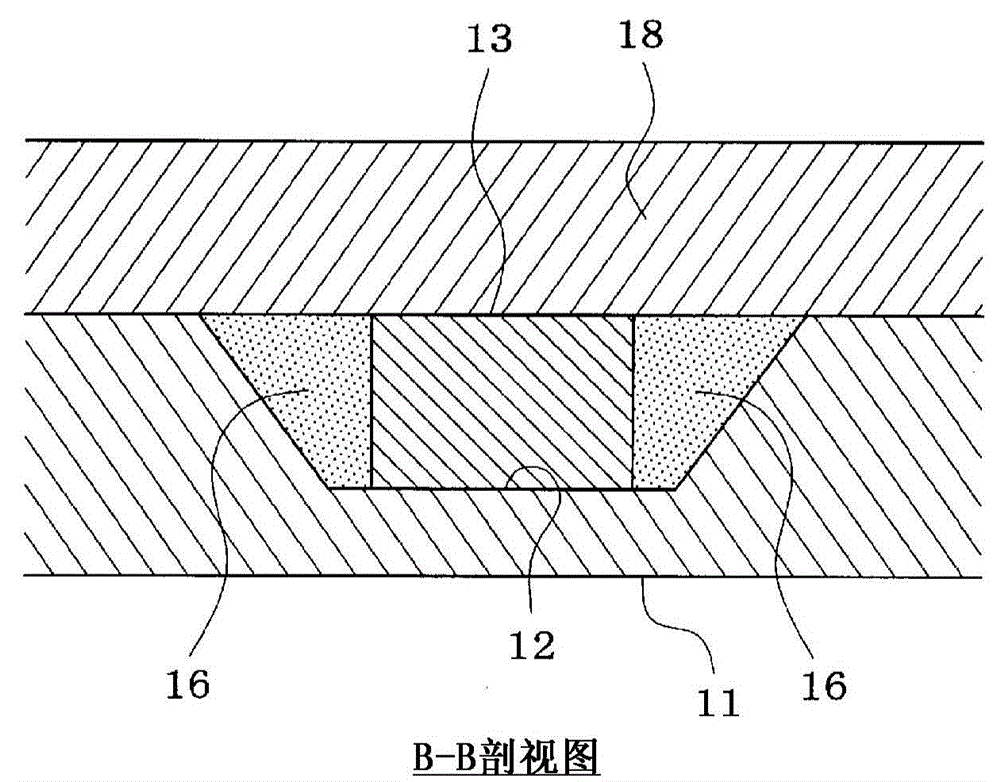

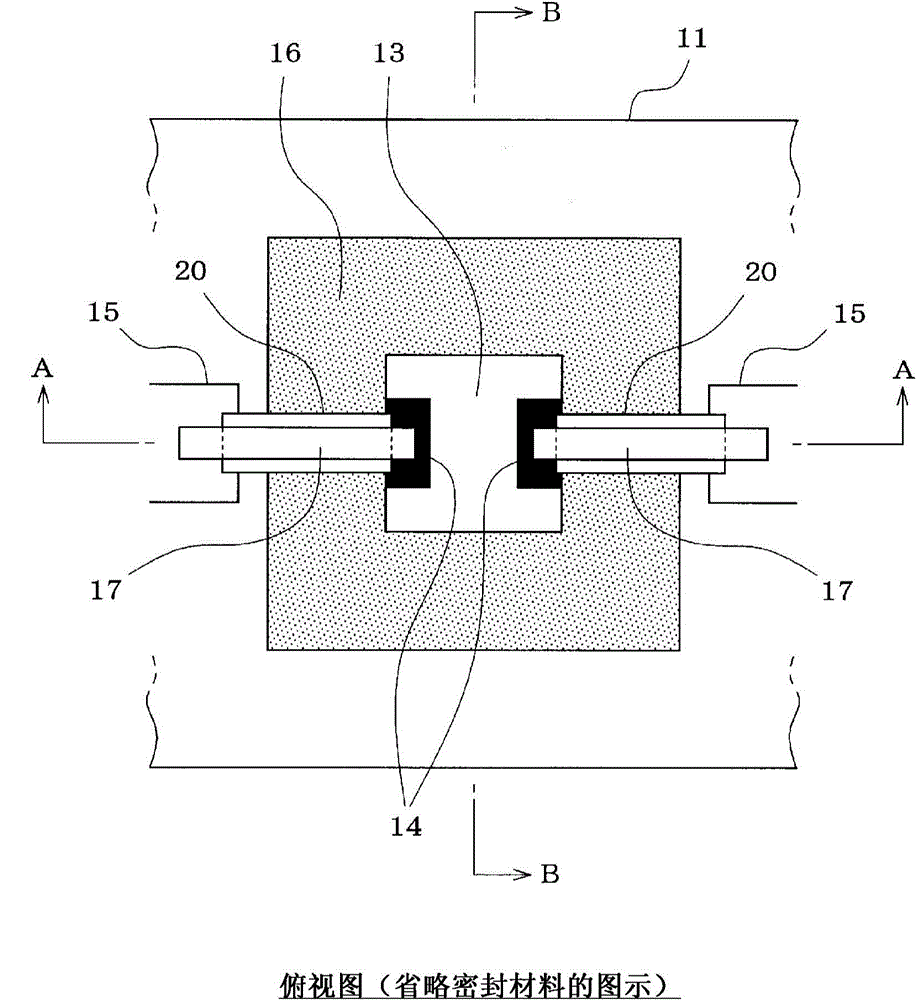

[0060] based on Figure 1 to Figure 3 Embodiment 1 of the present invention will be described.

[0061] The mounting member 11 is formed of a lead frame, a circuit board, or the like, and an element mounting recess 12 is formed at a predetermined position thereof. An LED element 13 (light emitting element) which is a semiconductor element is die-bonded (bonded) to the central portion of the bottom surface of the element mounting recess 12 of the mounting member 11 . The depth dimension (height dimension) of the element mounting recess 12 is set to be approximately the same as the height dimension of the LED element 13, and the electrode portion 14 mounted on the upper surface of the LED element 13 in the element mounting recess 12 is formed so as to be on the upper surface of the mounting member 11. The electrode parts 15 are approximately the same height.

[0062] The periphery of the LED element 13 in the element mounting recess 12 of the mounting member 11 is filled with ...

Embodiment 2

[0071] based on Figure 4 to Figure 6 Embodiment 2 of the present invention will be described.

[0072] The mounting member 30 is configured by molding a package main body 33 having an element mounting recess 32 on a lead frame 31 from resin. An LED element 34 (light emitting element) which is a semiconductor element is die-bonded (bonded) to the central portion of the bottom surface of the element mounting recess 32 of the mounting member 30 . The depth dimension (height dimension) of the element mounting recess 32 is set to be approximately the same as the height dimension of the LED element 34, and the electrode portion 35 on the upper surface of the LED element 34 mounted in the element mounting recess 32 is formed on the upper surface of the mounting member 30. The electrode portions 31 a of the lead frame 31 have substantially the same height.

[0073] A transparent base resin layer 36 is formed by filling a transparent insulating resin around the LED element 34 in the...

Embodiment 3

[0081] Next, based on Figure 7 Embodiment 3 of the present invention will be described.

[0082] The mounting member 41 is configured by molding a package main body 44 having an element mounting recess 43 formed of a sloped side surface on the lead frame 42 from resin. An element mounting portion 42 a (die pad) of the lead frame 42 is exposed on the bottom surface of the element mounting recess 43 , and an LED element 45 (light emitting element) as a semiconductor element is die-bonded (bonded) to the element mounting portion 42 a.

[0083] Two electrode portions 47 connected to the two electrode portions 46 on the upper surface of the LED element 45 are formed on an inclined side surface of the element mounting recess 43 . Each electrode portion 47 is integrally formed with the lead frame 42 . In this case, considering that the wider the width in the height direction of the electrode portion 46 formed on the side surface of the element mounting recess 43 is, the wider the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com