Method for controlling dynamic shearing of hot continuous rolling mill

A technology of hot continuous rolling mill and control method, which is applied in the direction of rolling mill control device, metal rolling, metal rolling, etc., and can solve problems such as affecting the yield of strip steel and difficult control of shearing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

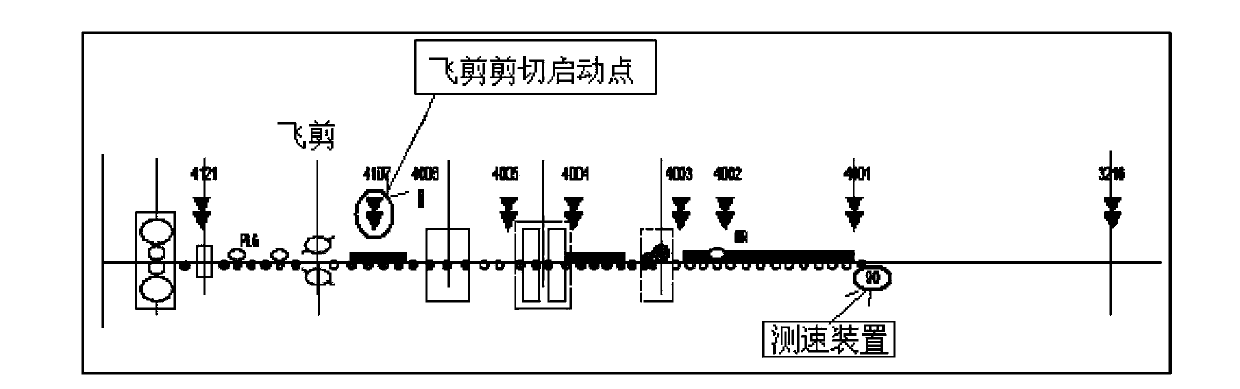

Image

Examples

Embodiment 1

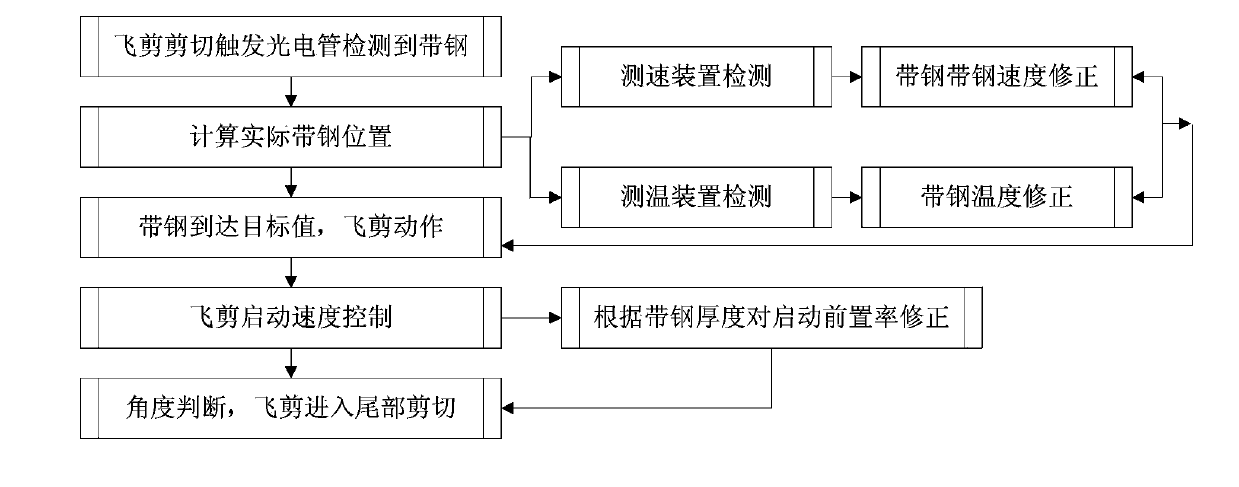

[0060] The flying shear triggers the photocell to detect the strip steel;

[0061] When the strip arrives at the flying shear, the photoelectric cell is started, and the program begins to track the head of the strip. Since the photoelectric cell starts to track the position of the strip head according to the temperature of the strip, the response of the photoelectric cell varies with the temperature of the strip. Therefore, the starting point of strip head tracking needs to be corrected for different temperatures.

[0062] Calculate the actual position of the strip head;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com