Laser cutting machine

A laser cutting machine and frame technology, applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of thermal damage to parts, low work efficiency, and difficult removal of debris, so as to prevent position changes, The effect of fast feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

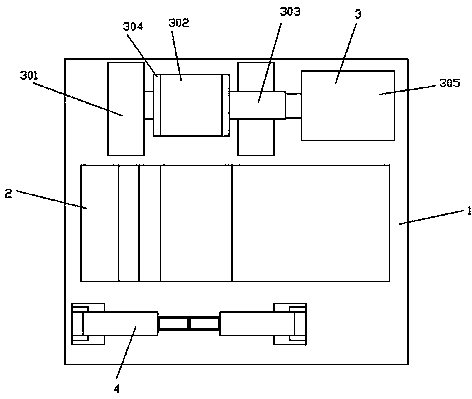

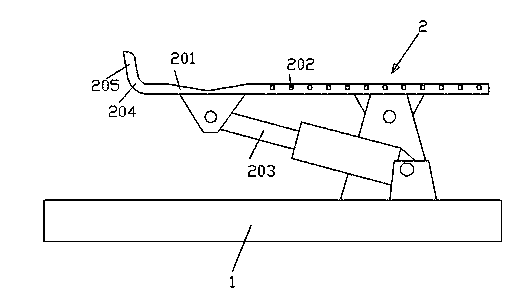

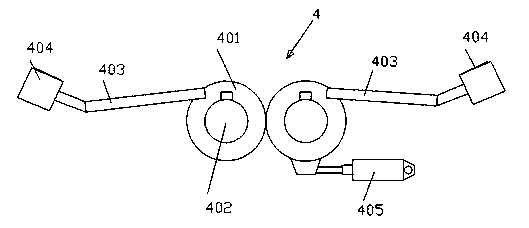

[0025] example, see attached figure 1 , 2 , 3; a laser cutting machine, including a frame, the frame is provided with a pipe feeding device, a workpiece conveying device for conveying the pipe conveyed by the pipe feeding device, and a pipe conveying device conveyed by the workpiece conveying device. Rotary clamping device for clamping, laser head device for cutting the pipe clamped by the rotary clamping device, and unloading device, the pipe feeding device includes a raceway or conveyor chain on which the pipe is placed It is conveyed into the laser cutting machine, and then the workpiece conveying device conveys the pipe in the laser cutting machine, and aligns the pipe while conveying, so that the center line of the pipe is consistent with the conveying direction, and then the pipe is rotated by the clamping device. Clamp, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com