wind turbine nacelle

A technology for wind turbines and nacelles, which is applied in wind turbines, wind power generation, engines, etc., can solve problems such as economic losses, difficulty in maintaining and replacing large parts and components, and dangers, so as to prevent rain leakage and be convenient, economical and practical. , to avoid the effect of unsafe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

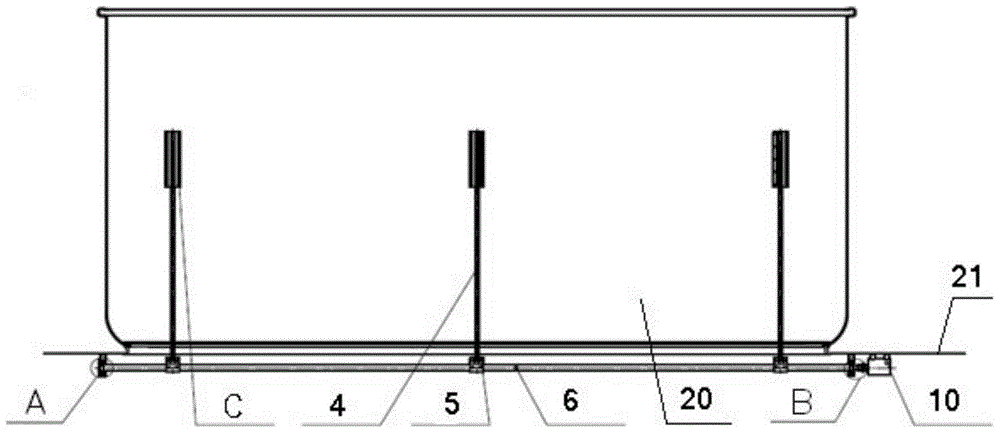

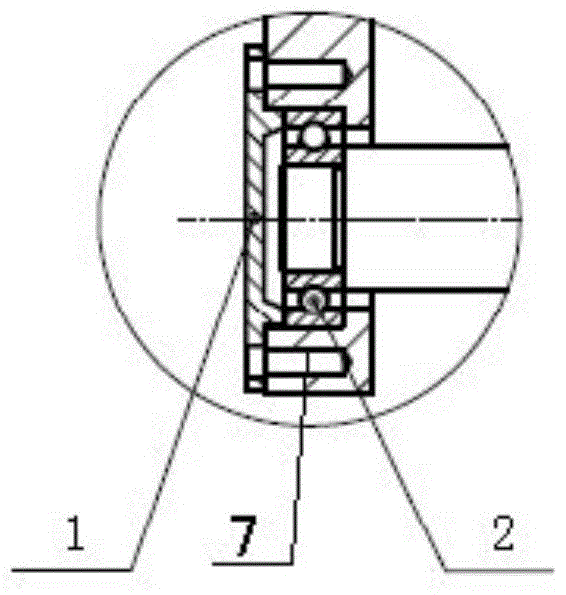

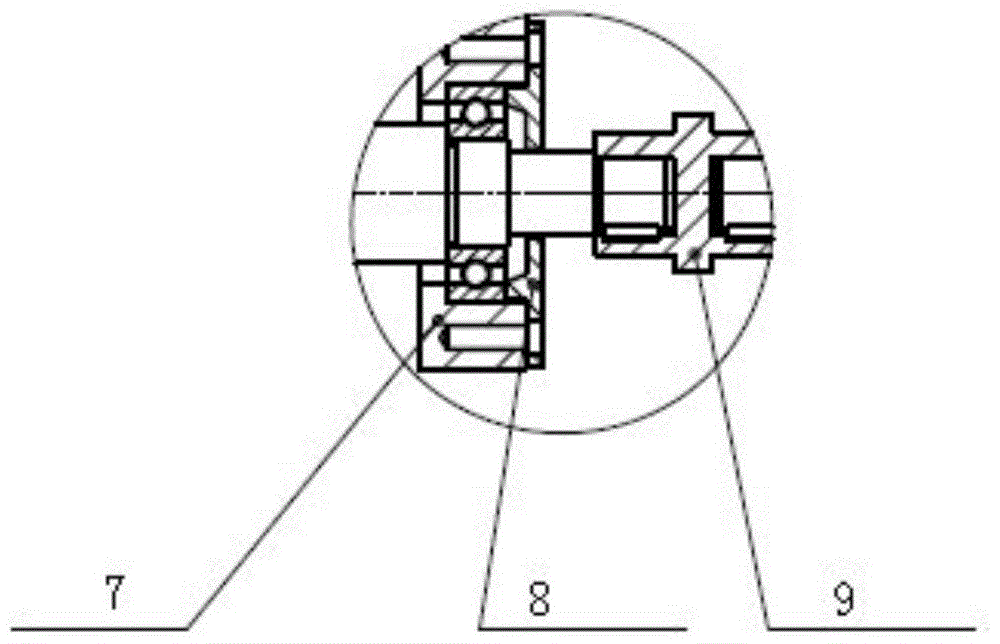

[0029] Refer to attached Figures 1 to 4 It can be seen that the automatic door of the present invention includes a door frame 21 and a door body 20 matched with the door frame 21 . The automatic door also includes an automatic door opening and closing mechanism. The automatic door opening and closing mechanism includes a pulley assembly C installed on the inner wall of the door body 20, a support rod 4 connected to the pulley assembly C, a rotating shaft 6 for fixing the support rod 4, and a fixed rotation The fixed parts A, B of the shaft 6 and the power part 10 for rotating the rotary shaft 6, the fixed parts A, B and the power part 10 are installed on the door frame 21 inside the automatic door or on the wall where the door frame 21 is installed. The power component 10 of the rotating shaft 6 can be an electric motor, a rotating hydraulic cylinder, etc., and the electric motor or rotating hydraulic cylinder is connected to one end of the rotating shaft 6 through a bushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com