Smoke recycling pulverized coal boiler combustion system and working condition switching method thereof

A flue gas recirculation, pulverized coal boiler technology, applied in the control of combustion, indirect carbon dioxide emission reduction, lighting and heating equipment, etc., to achieve the effect of combustion switching control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

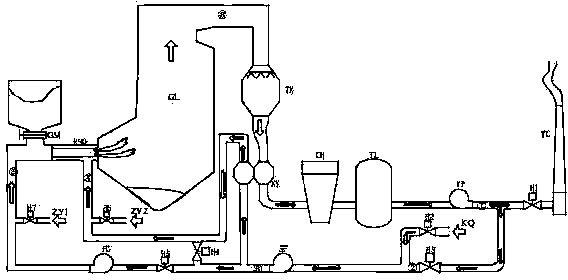

[0039] An embodiment of the flue gas recirculation pulverized coal boiler combustion system of the present invention, as figure 1 As shown, it includes sequentially connected coal feeder GM, burner RSQ, boiler GL, denitrifier TX, air preheater KY, ash removal device CH, desulfurization device TL and induced draft fan YF;

[0040] The induced draft fan YF is respectively connected to the inlet of the exhaust valve H1 and the inlet of the recirculation valve H3 through pipelines, the outlet of the exhaust valve H1 is connected to the chimney YC, the inlet of the intake valve H2 is connected to the air KQ, the outlet of the intake valve H2 is connected to the recirculation valve H3 The outlet is connected to the inlet of the blower SF through the pipeline, and the outlet of the SF blower is connected to the air inlet of the air preheater KY, the inlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com