Hydrostatic test system and method based on distributed structural gas cylinder external measurement method

A distributed structure, hydraulic test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as low test efficiency, gas cylinder blockage, etc., to achieve a friendly human-machine interface, improve efficiency, and improve testing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

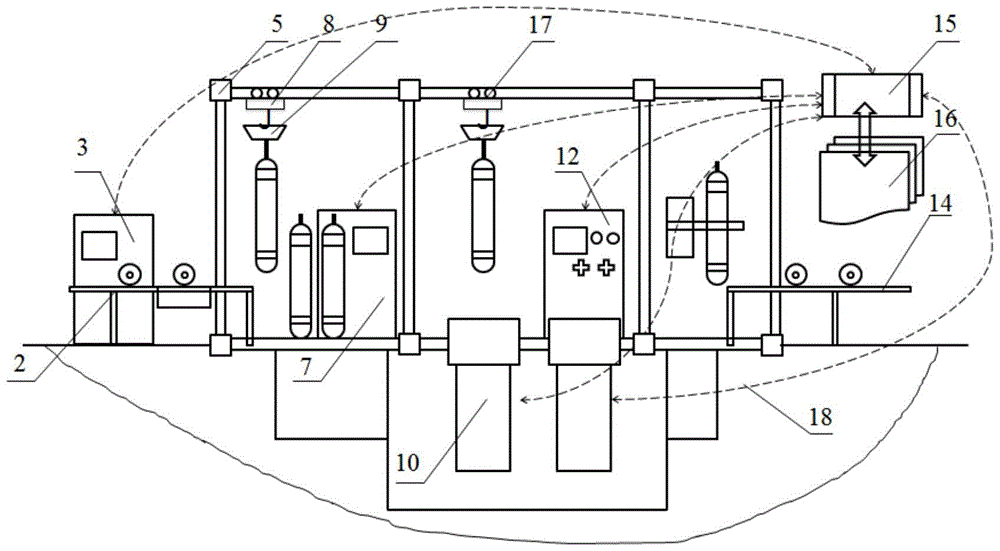

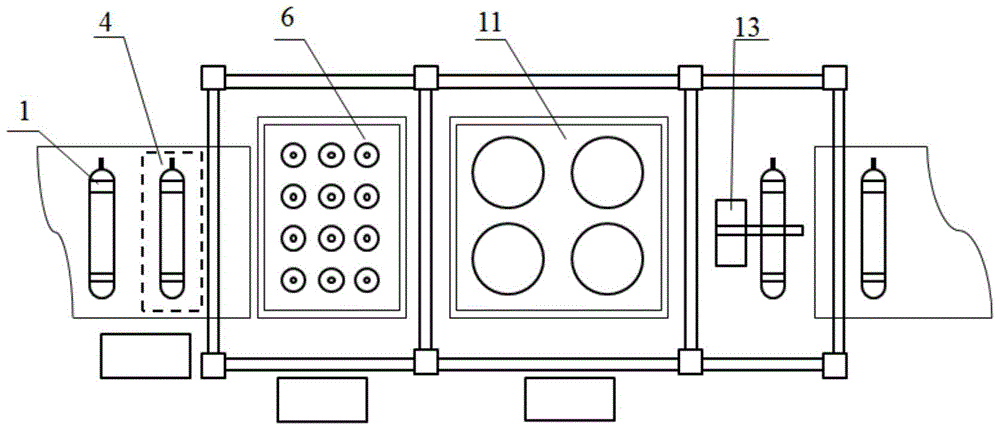

[0027] Based on the distributed structural gas cylinder external measurement method hydraulic test system, it consists of a gas cylinder to be tested 1, a material feeding logistics line 2, an air cylinder weighing platform, a water injection pipe, a water-filled gas cylinder weighing platform, and a hydraulic test platform 11, Water discharge device 13, unloading logistics line 14, upper support frame 5 for gas cylinder transmission, pulleys and hooks on the upper support frame 5, hanging electronic scale with wireless transmission function 8, standard water jacket 10, water jacket Cover 9, desktop electronic scale 4, router 15, computer, network components, a network data engine, air bottle weighing control cabinet 3, full water weighing control cabinet 7 and hydraulic test control cabinet 12; in the loading logistics line The end of 2 fixes the air cylinder weighing platform, the water-filled gas cylinder weighing platform 6, the hydraulic test platform 11, the water dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com