Multi-stage fermentation process fault monitoring method based on self-adaption FCM algorithm

A fermentation process and fault monitoring technology, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

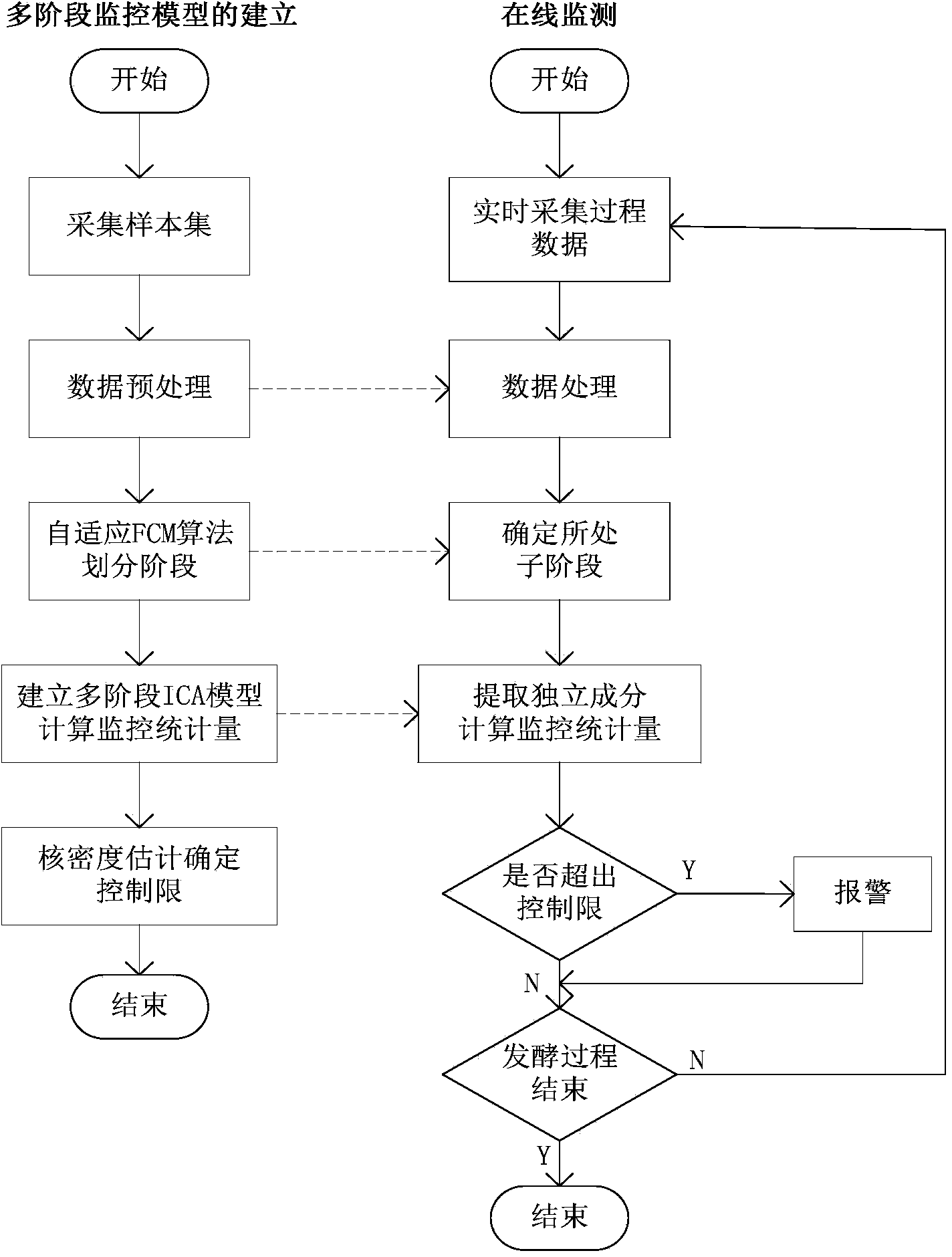

Method used

Image

Examples

Embodiment Construction

[0063] Provide following embodiment in conjunction with content of the present invention:

[0064] As an antibiotic, penicillin has high clinical medical value, and its production and fermentation process is a typical multi-stage batch operation process. The Pensim simulation platform used in this paper was developed by Professor Cinar of Illinois Institute of Technology (IIT) and his research technology group. This simulation platform is specially designed for the penicillin fermentation process and has a certain international influence.

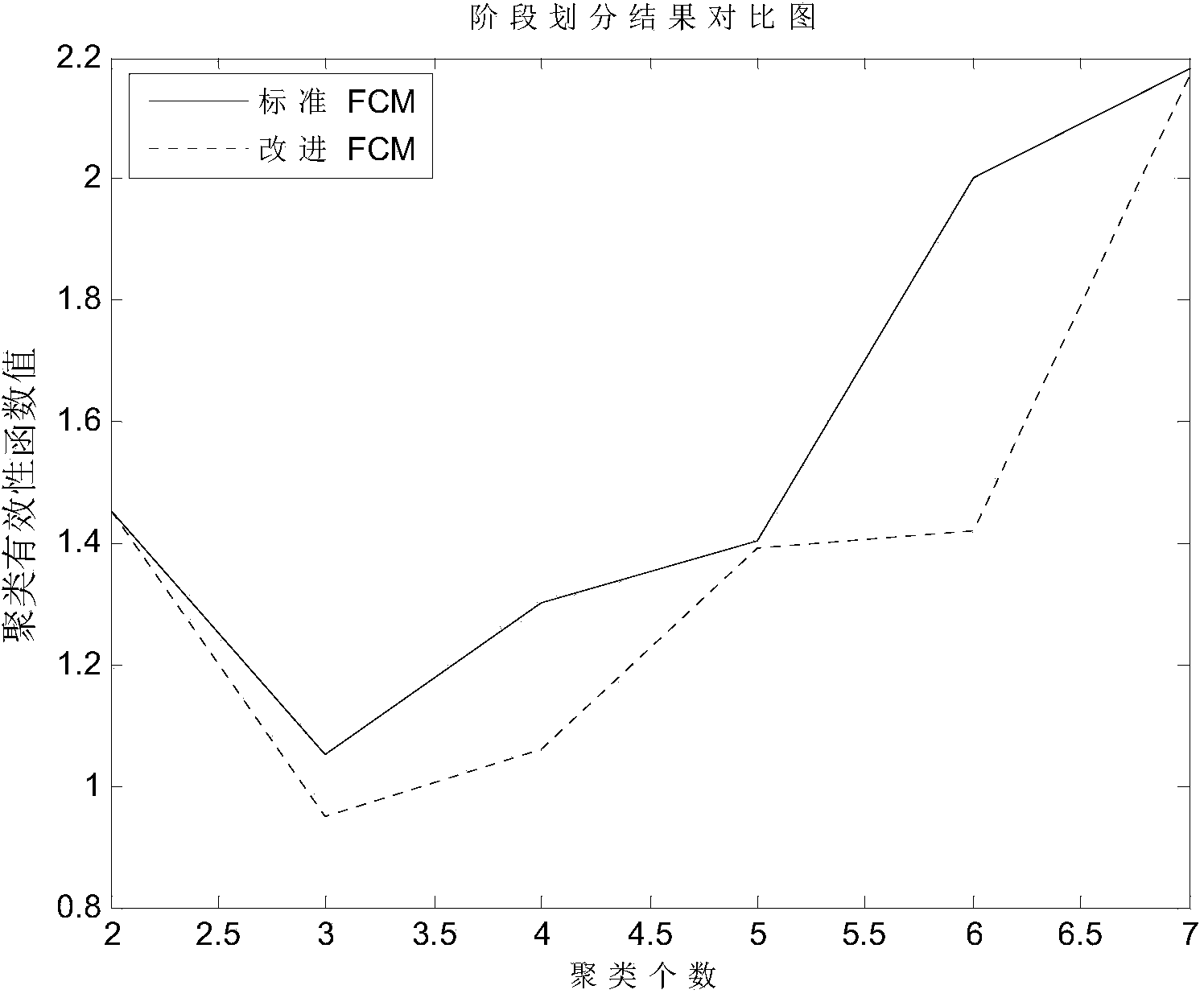

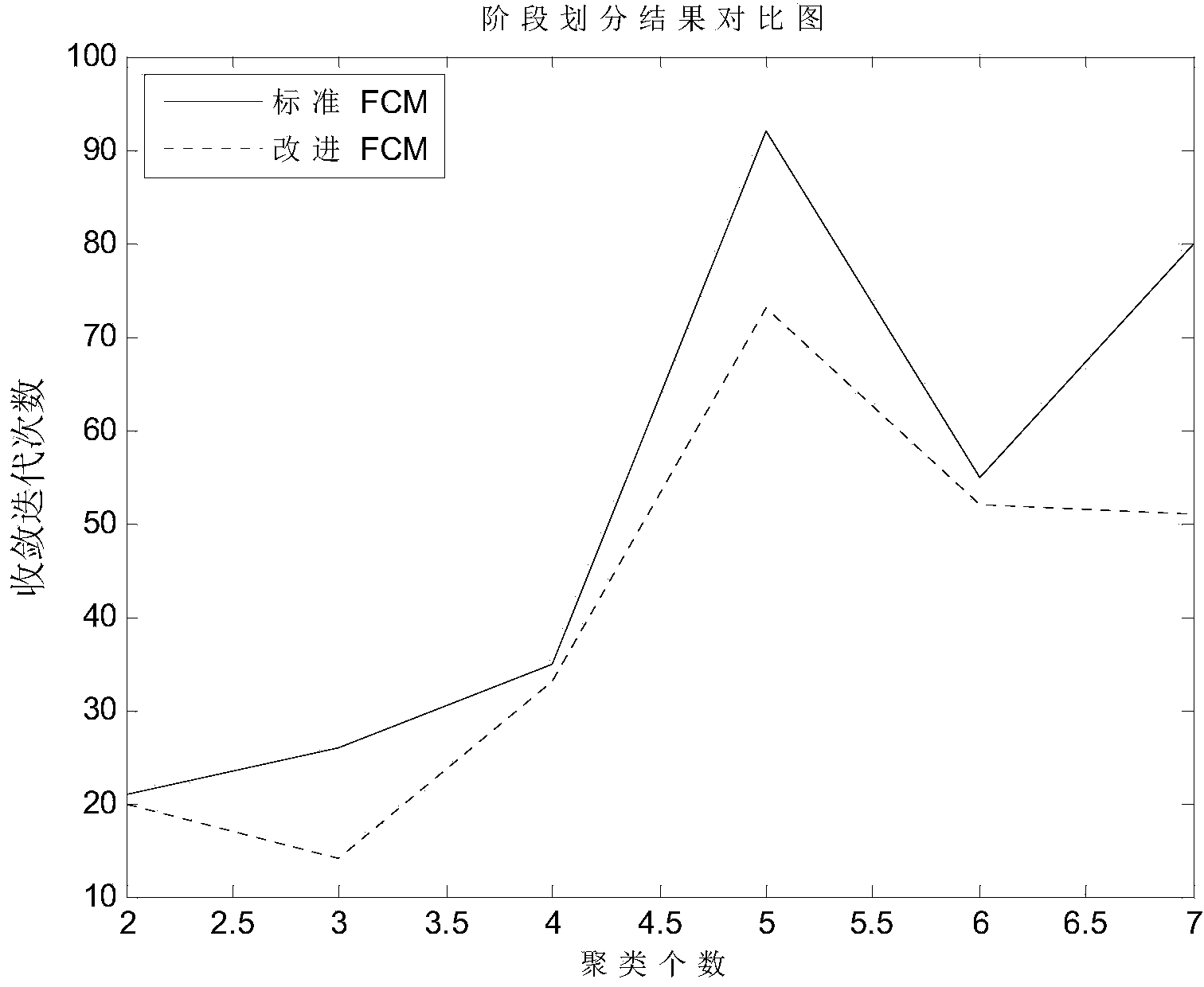

[0065] The on-line observable variables that affect the penicillin fermentation process mainly include temperature, substrate flow acceleration, substrate concentration, air flow, stirring power, etc. The present invention selects 10 process variables (shown in Table 1) for monitoring. A complete batch of penicillin fermentation time is about 400 hours, sampling once every hour, a batch can get 400 sampling moments. The simulation experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com