Method for managing an alternator combined with at least one power battery and driven by a heat engine

An alternator, heat engine technology, applied in the direction of using engine-driven traction, battery circuit device, auxiliary motor power supply, etc., can solve problems such as excessive fuel consumption, deactivation, and limiting lithium battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

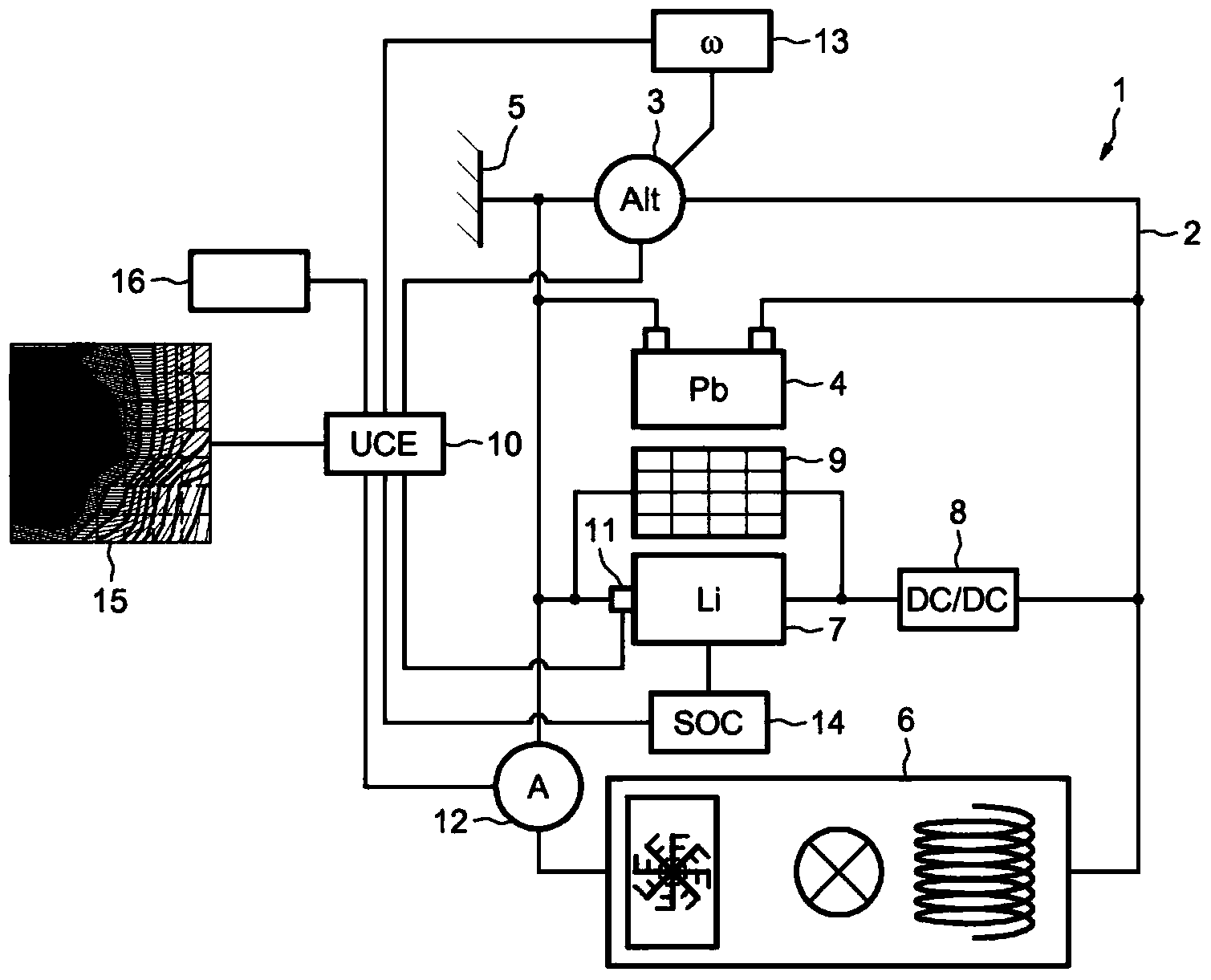

[0033] Such as figure 1 As shown in , an electric power supply system 1 for a vehicle comprises an electric power network 2, an alternator 3, a first battery 7 (such as a lithium-ion type battery), a second battery 4 (such as a lead battery) and An electronic control unit 10 . The first battery 7 is equipped with a switch 11 allowing it to be disconnected from the network 2 . The alternator 3 is capable of converting mechanical energy extracted from a shaft linked to a heat engine (not shown) into electrical energy for transmission on the electrical network 2 . The power supply system also includes an ammeter 12, a meter 13 and a state of charge estimator 14, the ammeter inserted in the network 2 and connected in series with the consumers 6, so as to be able to measure The total current absorbed by the elements, the meter is able to estimate the instantaneous rotational speed ω of the alternator 3 (e.g. by directly measuring the rotational speed of the alternator, or by meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com