Catalytic CVD and device therefor

A catalyst and catalyst body technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as the inability to maintain temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

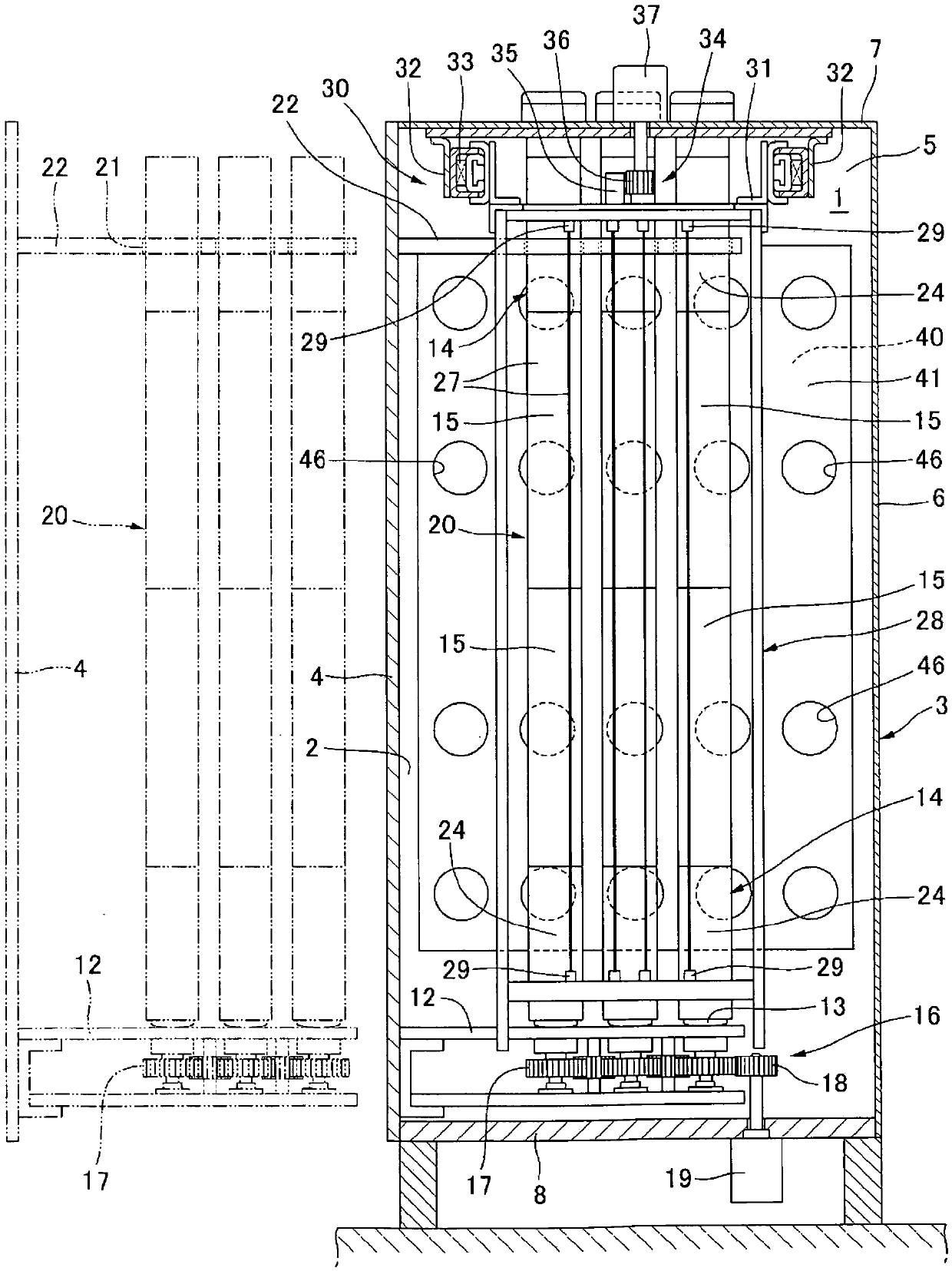

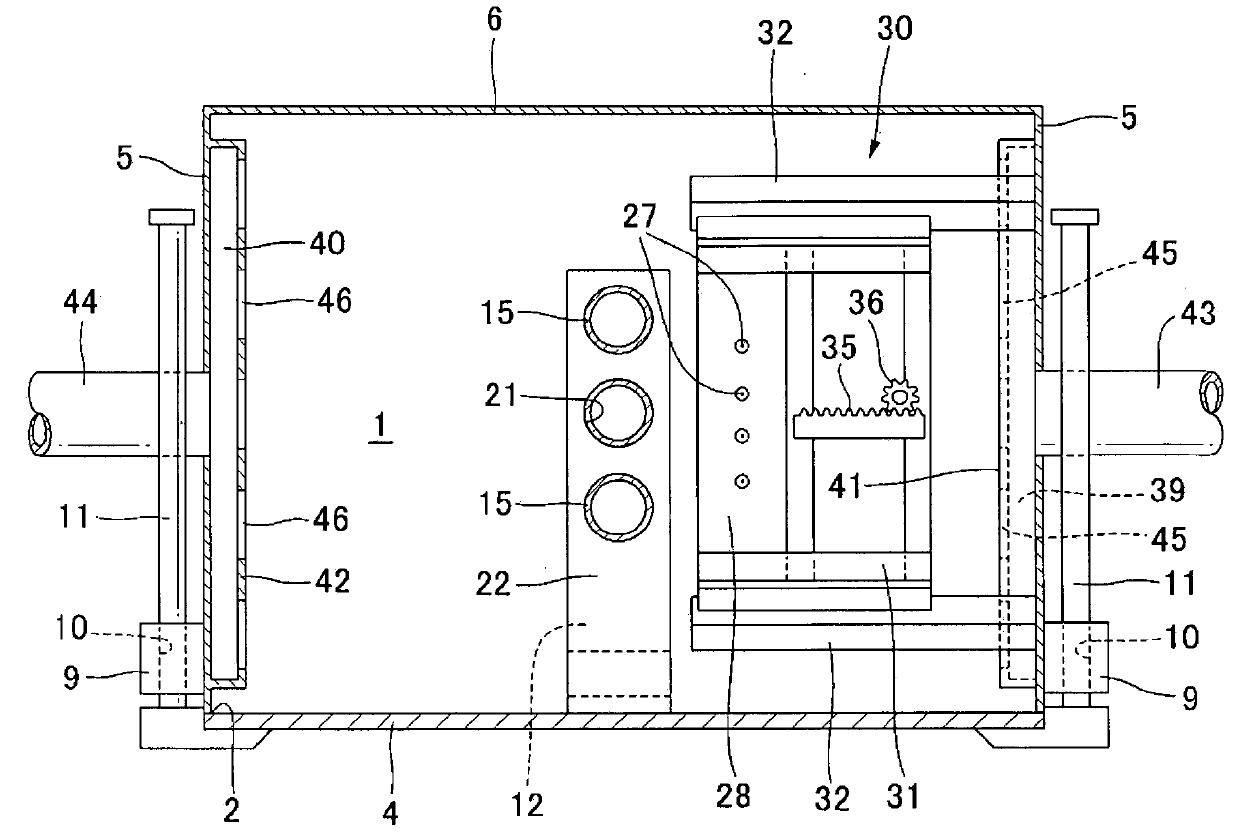

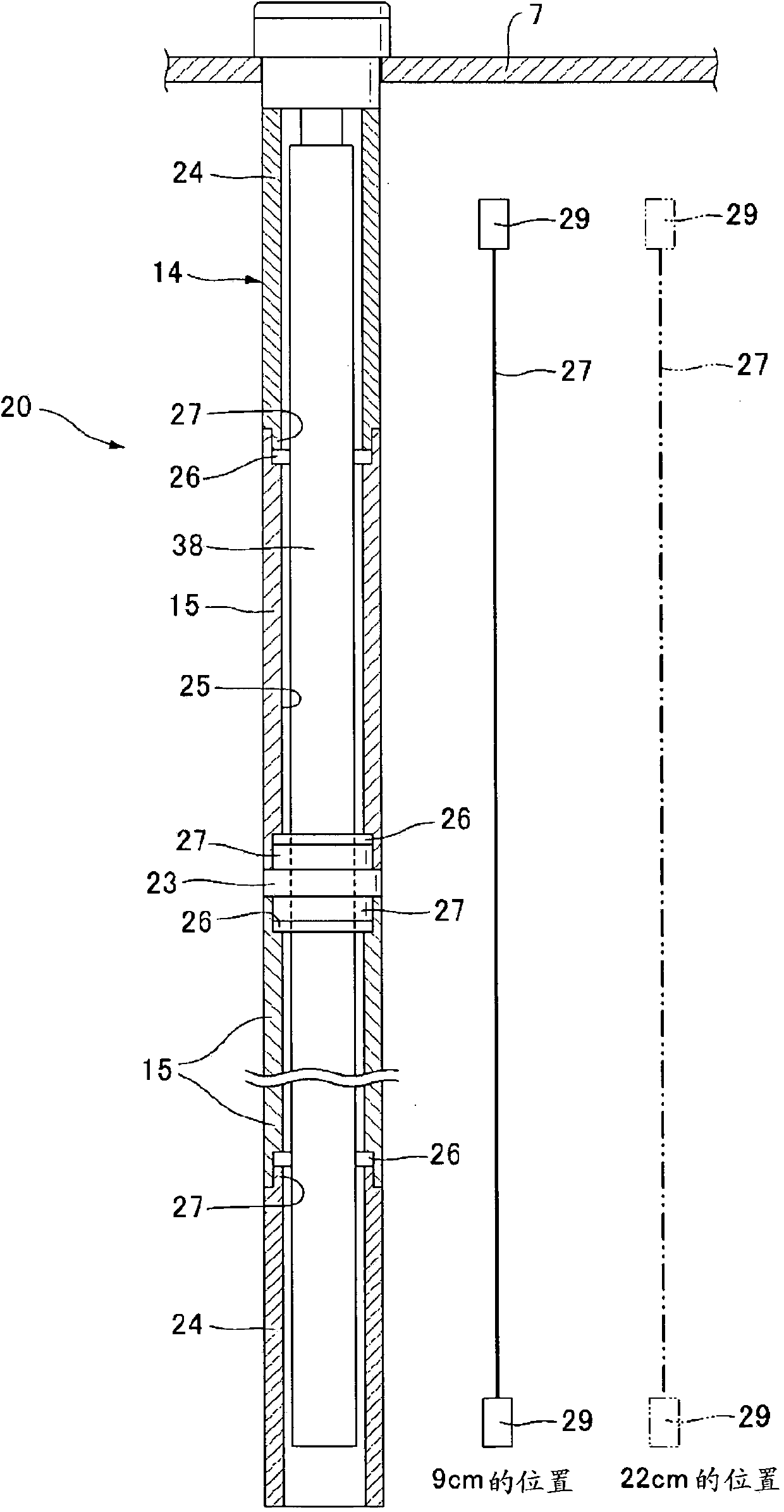

[0028] According to the present invention, it is assumed that a 30 μm amorphous silicon-based film is formed on a cylindrical substrate. During the film formation process, the vacuum degree of the reaction chamber was 10 6 Pascal, the heating temperature of the linear catalyst body was 1750°C. The wire-shaped catalyst body is composed of tungsten wires with a diameter of 0.7 mm or 0.6 mm and a length of 75 cm, and the number of wires is four. In the process of forming the charge injection preventing layer and the photoconductive layer, the linear catalyst body was set at a distance of 9 cm from the cylindrical base, and the heating temperature of the cylindrical base was 250°C. When forming the surface protective layer, the linear catalyst body was retreated from the cylindrical substrate by a distance of 22 cm, and the heating and cooling device was controlled so that the temperature of the cylindrical substrate was 180°C to 150°C.

[0029] SiH that forms the charge injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com