Adsorption dehumidification process method and device

A process method and dehumidifier technology, applied in the field of dehumidification, can solve the problems of low energy consumption and large energy consumption, and achieve the effect of lowering the temperature and improving the dehumidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

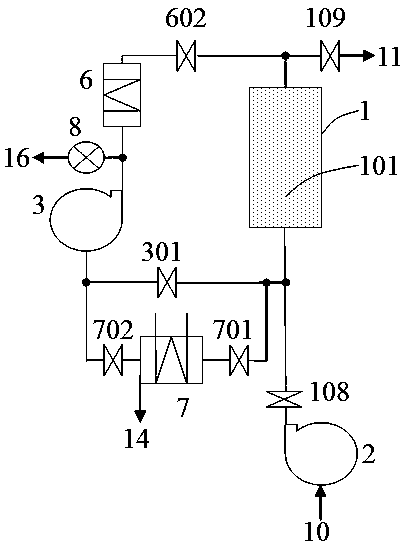

[0107] Such as figure 1 As shown, it is a schematic diagram of an intermittent dehumidification device equipped with a condenser in a regeneration circuit in the present invention. The dehumidification device includes an adsorption dehumidifier 1 (with a hygroscopic agent bed 101 composed of hygroscopic agent particles inside), an inlet 10 for gas to be dehumidified , Dehumidified gas outlet 11, dehumidification fan 2, circulation fan 3, regeneration heater 6, condenser 7. The gas inlet 10 to be dehumidified, the dehumidifying fan 2, the adsorption dehumidifier 1, and the dehumidified gas outlet 11 are connected through pipelines to form a dehumidified gas path. The adsorption dehumidifier 1, the circulating fan 3, and the regeneration heater 6 are connected through pipelines to form a regeneration circuit; both ends of the condenser 7 are connected to the regeneration circuit through pipelines to form a condensation branch, and the valves 301, 701, and 702 can be used to adju...

Embodiment 2

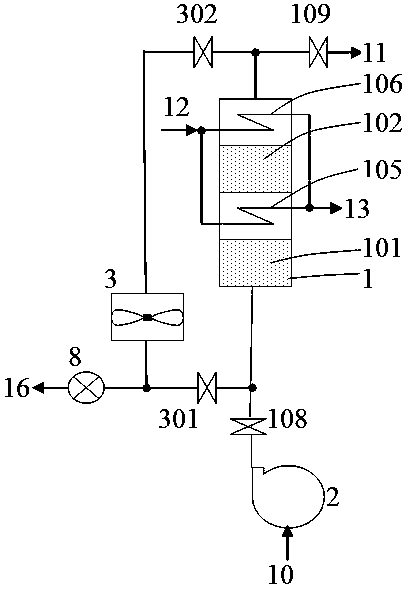

[0121] Such as figure 2 Shown is another intermittent adsorption dehumidification device of the present invention.

[0122] The adsorption dehumidifier 1 has hygroscopic agent beds 101, 102 composed of hygroscopic agent particles and heat exchange tubes 105, 106 spaced apart from the hygroscopic agent beds 101, 102. The heat exchange surfaces of , 106 are in contact with each other to avoid local overheating of the moisture absorbent beds 101, 102; the circulation fan 3 is a two-way axial flow fan; An operating cycle of the device includes dehumidification, regeneration steps:

[0123] (A) Dehumidification: Cooling medium is introduced into the heat exchange tubes 105, 106, valves 108, 109 are opened, other valves are closed, and the dehumidification fan 2 is operated, so that the gas to be dehumidified entering through the inlet 10 flows through the adsorption dehumidifier 1, and the gas The moisture in the gas is adsorbed and removed by the hygroscopic agent beds 101 and ...

Embodiment 3

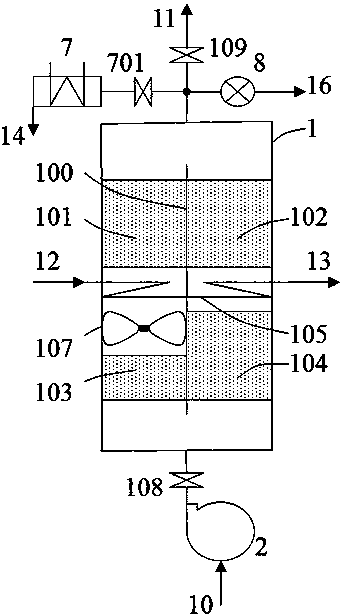

[0134] Such as image 3 Shown is another intermittent adsorption dehumidification device of the present invention.

[0135] The adsorption dehumidifier 1 has moisture absorbent beds 101, 102, 103, 104 composed of moisture absorbent particles, heat exchange tubes 105, and circulation fan 107; the partition 100 divides the interior of the adsorption dehumidifier 1 into two chambers. Running the circulation fan 107 can circulate the gas in the adsorption dehumidifier 1 . An operation cycle of the dehumidification device also includes dehumidification and regeneration steps. When the water needs to be discharged, the valve 701 can be opened. Since the gas pressure in the adsorption dehumidifier 1 is higher than the pressure in the condenser 7, the gas in the adsorption dehumidifier 1 enters the condenser 7, and the water vapor contained in the gas is condensed, and the condensed water is discharged from the port 14 out. The advantage of the dehumidification device with built-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com