Bipolar electrode device for electric spark hole machining for insulating ceramic material

A bipolar electrode and insulating ceramic technology is applied in the field of machining, which can solve the problems of poor stability and unsustainable machining of the electric spark hole of insulating ceramics, and achieves the effects of improved stability, simple structure and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

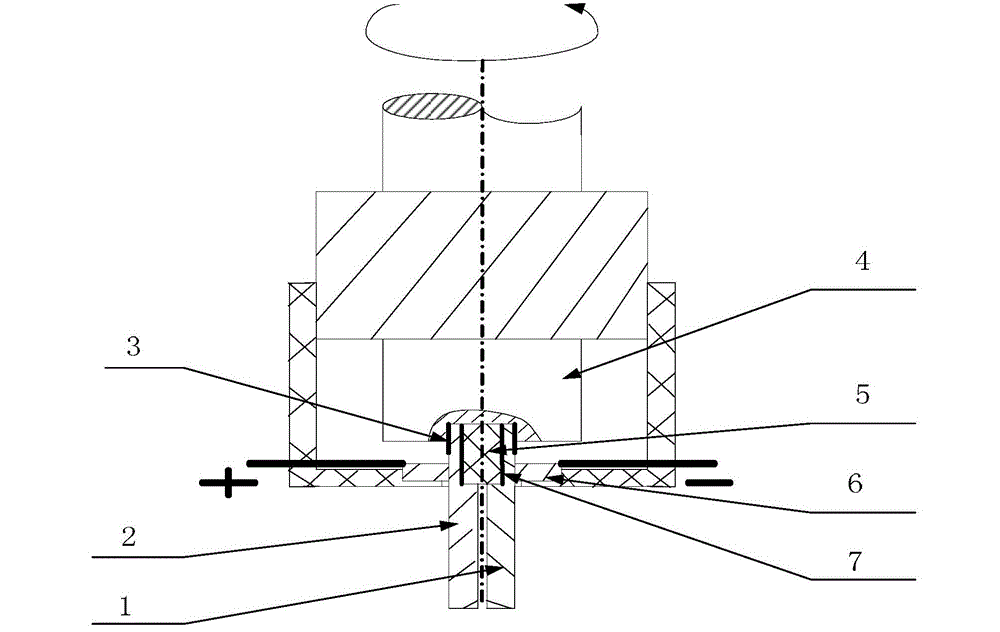

[0016] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode, a bipolar electrode device for electric discharge hole machining of insulating ceramic materials described in this embodiment mode, it includes a rotating spindle 4, a first bipolar electrode 1, a second bipolar electrode 2, an insulating Set 3, insulation commutation block 5 and polarity conversion brush 6;

[0017] The first bipolar electrode 1 and the second bipolar electrode 2 are respectively fixed on both sides of the insulating reversing block 5 to form a whole, which is fixedly connected to the rotating main shaft 4 through the insulating sleeve 3;

[0018] The positive terminal of the polarity conversion brush 6 is connected with the positive terminal of the pulse power supply, and the negative terminal of the polarity conversion brush 6 is connected with the negative terminal of the pulse power supply;

[0019] The polarity switching brush 6 is an annular struc...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment further limits the bipolar electrode device for EDM hole machining of insulating ceramic materials described in Embodiment 1. In this embodiment, it also includes an adjustment gasket 7, the first Between the bipolar electrode 1 and the insulating commutation block 5 , and between the second bipolar electrode 2 and the insulating commutation block 5 , an adjusting gasket 7 is arranged.

specific Embodiment approach 3

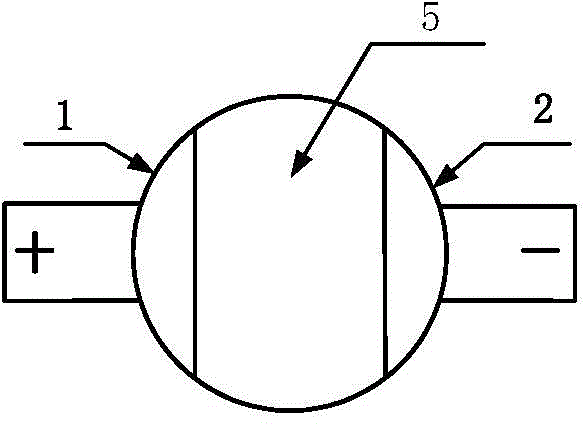

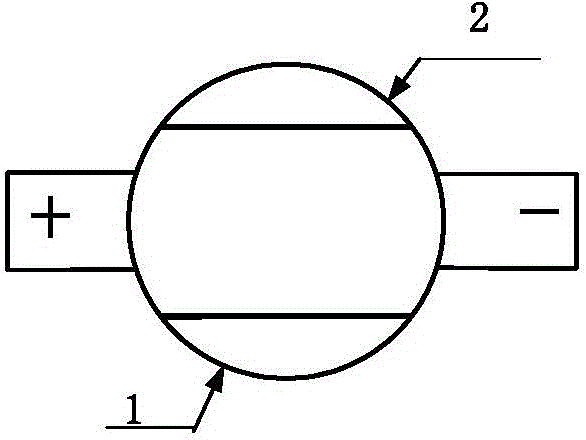

[0022] Embodiment 3: This embodiment further limits the bipolar electrode device for EDM hole machining of insulating ceramic materials described in Embodiment 1. In this embodiment, the first bipolar electrode 1 and the second The shapes of the bipolar electrodes 2 are both half cylinders.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com