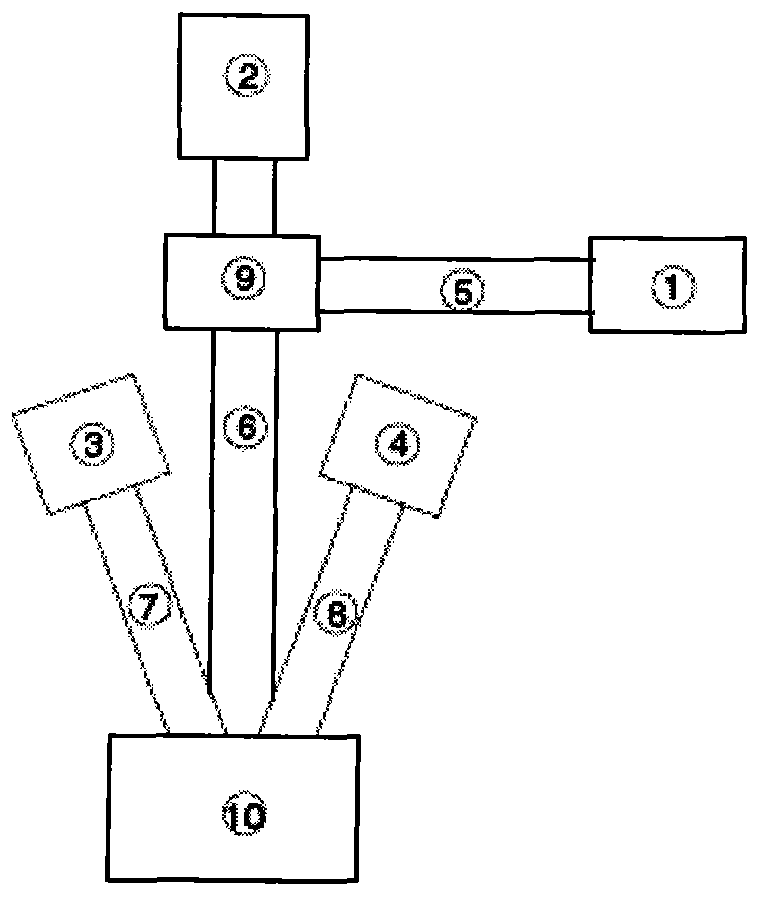

Four-motor physical foaming co-extrusion device

A technology of co-extrusion physical foaming and extruding machine, applied in the field of physical foaming extruding device, can solve the problems of increasing the difficulty of processing and assembling the screw and barrel, affecting the plasticization and extrusion quality of plastics, and reducing the service life, etc. The effect of increasing screw transmission power and plasticizing capacity, improving overall efficiency and product quality, and improving efficiency and product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the invention is described in further detail:

[0016] as attached figure 1 A four-machine co-extrusion physical foaming extrusion device shown includes a polyethylene foaming extruder motor 1, a polyethylene conveying extruder motor 2, an outer layer extruder motor 3, an inner layer extruder motor 4, a polyethylene extruder motor Foam extruder 5, polyethylene transfer extruder 6, outer layer extruder 7, inner layer extruder 8, extruder adapter 9 and three-layer co-extrusion head 10, the screw of the polyethylene foam extruder 5 directly 20mm, the length-to-diameter ratio is 36:1, and the compression ratio is 2:1. The screw diameter of the polyethylene conveying extruder 6 is 20mm, the length-to-diameter ratio is 36:1, and the compression ratio is 2.8:1. The diameter of the screw of the layer extruder 7 and the inner layer extruder 8 is 25 mm, the length-to-diameter ratio is 28:1, and the compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com