Frame sealing adhesive, packaging method of display panel, and display panel

A display panel and packaging method technology, applied in optics, instruments, adhesive additives, etc., can solve problems such as liquid crystal pollution, sealant puncture, display panel yellowing, etc., to reduce impact force, avoid pollution, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

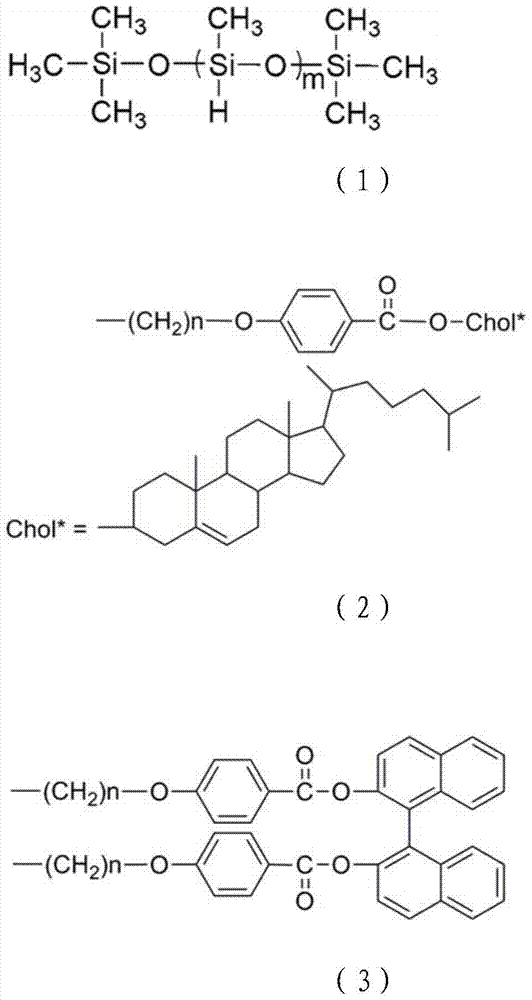

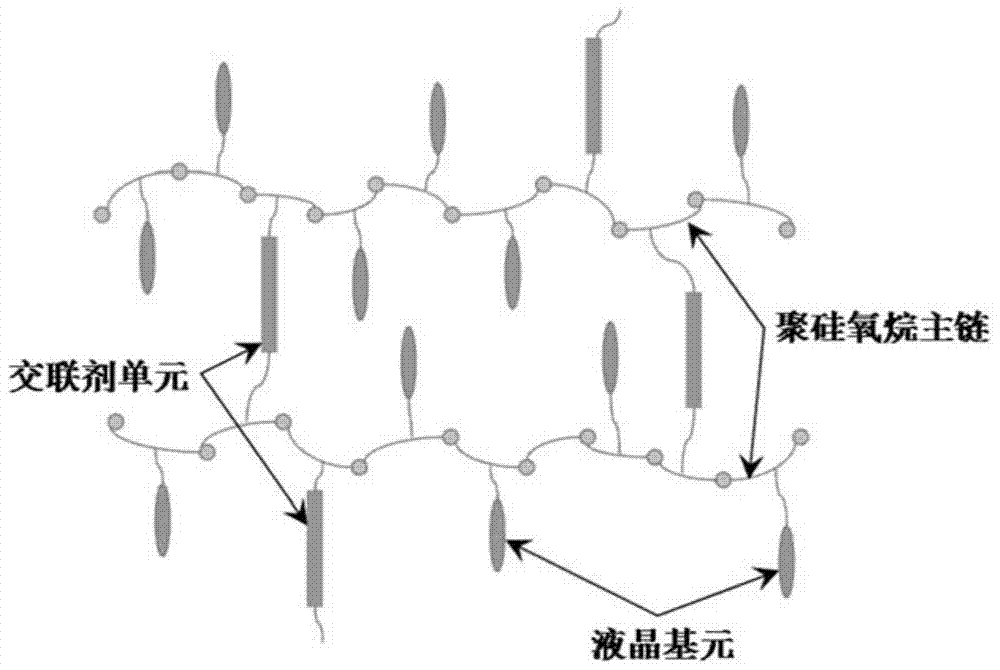

[0047] A frame sealant, comprising a frame sealant matrix and a siloxane side chain type liquid crystal elastomer, the siloxane side chain type liquid crystal elastomer is composed of a polymethylhydrogen siloxane main chain, a liquid crystalline monomer and a cross-linked The linking agent is formed through hydrosilylation reaction, wherein the liquid crystal monomer is a cholesterol derivative, and the crosslinking agent is a binaphthyldiol derivative, that is, the crosslinking agent contains a binaphthyldiol group.

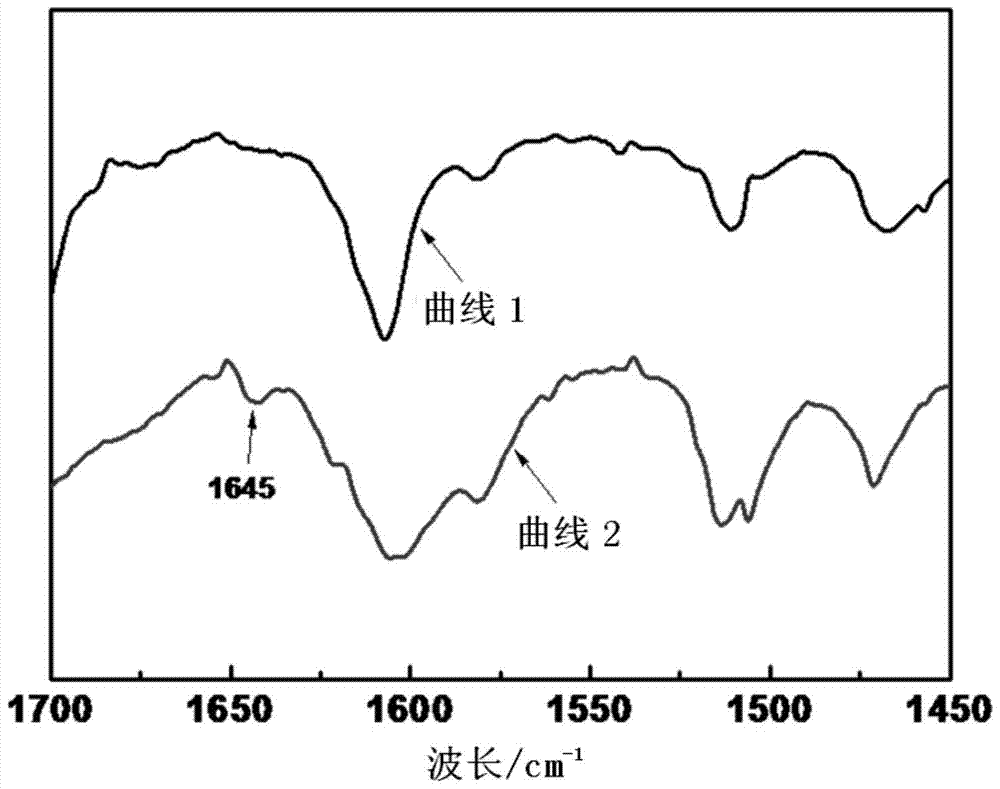

[0048] Among them, the liquid crystal monomer contains one double bond, and the crosslinking agent contains two double bonds. In the hydrosilylation reaction, the cross-linking agent p-alkenyloxybenzoic acid binaphthyl ester and the liquid crystal monomer p-alkenyloxybenzoic acid cholesteryl ester are grafted to the polymethylhydrogensiloxane main chain to form silicon Oxylkane side chain type liquid crystal elastomer. Among them, the number of Si-H bonds in t...

Embodiment 2

[0063] This embodiment provides a display panel and a packaging method for the display panel.

[0064] In this embodiment, the display panel includes a color filter substrate and an array substrate, and the color filter substrate and the array substrate are formed by encapsulating the frame sealant in the first embodiment.

[0065] Specifically, the packaging method of the display panel includes:

[0066] Step S1): The frame sealing glue matrix and the siloxane side chain type liquid crystal elastomer are uniformly mixed according to the mass ratio to form a mixture.

[0067] In this step, the siloxane side chain type liquid crystal elastomer is added to the frame sealant matrix according to the mass ratio, and stirred, so that the siloxane side chain type liquid crystal elastomer is evenly dispersed in the frame sealant matrix. Wherein, the mass fraction of the frame sealing glue matrix is 70-99.5%, and the mass fraction of the siloxane side chain type liquid crystal elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com