Device of improving yarn surface structure in positive holding rotation mode

A surface structure and rotary technology, applied in the field of textile processing, can solve problems such as weak twist, reduced hairiness, and inability to form dense structural connections, etc., to achieve the effect of improving wear resistance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

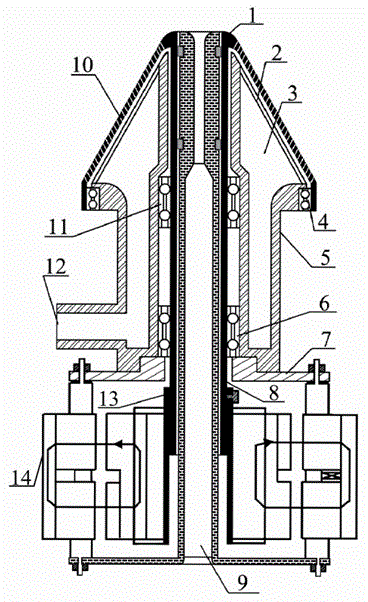

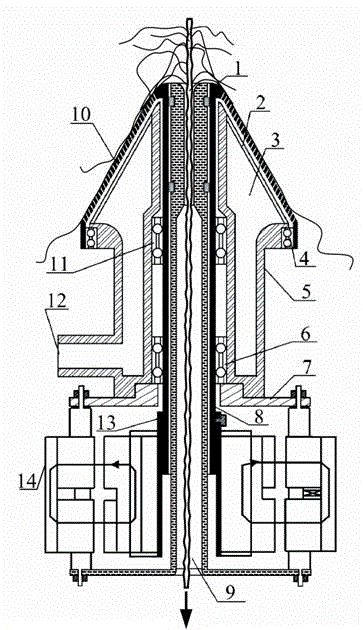

[0019] Example 1: In the process of ring spinning, improving the smoothness of ring spinning

[0020] On the ring spinning frame, the Houka fixing device is used, and the device for actively holding and rotating the yarn surface structure is fixed and installed between the front roller jaw and the yarn guide hook of the ring spinning frame through the air channel base 5. The motor 14 is connected to the power cord of the headstock of the ring spinning machine to obtain energy to drive the rotator 1, so that the rotator 1 rotates at a speed of 10,000-25,000 rpm, and actively holds the rotating device for improving the yarn surface structure through the air duct The air outlet 12 of the base 5 is externally connected with a negative pressure exhaust fan, so that a negative pressure is generated in the conical cover of the spinner 1 . The fiber sliver unwound from the roving package is drafted by the drafting system composed of the rear roller, rear rubber roller, middle roller, ...

Embodiment 2

[0021] Example 2: In the winding process, improving the smoothness and density of the ring-spun yarn surface structure

[0022] On the automatic winding machine, the Houka fixing device is used to fix and install the device for actively holding and rotating the yarn surface structure through the air channel base 5 between the electronic yarn clearer and the waxing device of the automatic winding machine. The micro motor 14 is connected to the power line in the control box to obtain energy to drive the rotator 1, so that the rotator 1 rotates at a high speed of 60,000 rpm, and actively holds the rotating device for improving the surface structure of the yarn through the air duct base 5 The air outlet hole 12 of the outside is connected with a negative pressure exhaust fan, so that a negative pressure is generated in the conical cover of the spinner 1. The Z-twisted yarn unwound from the bobbin package passes through the balloon breaker, pre-clearer, tension device, and electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com