Oblique incidence and reflection type point diffraction plate and interference measuring method thereof

A point-diffraction and reflection-type technology, applied in the field of optical interferometry, can solve problems such as difficulties in making polarized point-diffraction plates, failure to be widely used, complex system structure, etc., and achieve easy test implementation, simple optical path, and simple test process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The measurement of the transient wavefront of the large-aperture laser by using the oblique-incidence reflective point diffraction plate of the present invention includes the following steps:

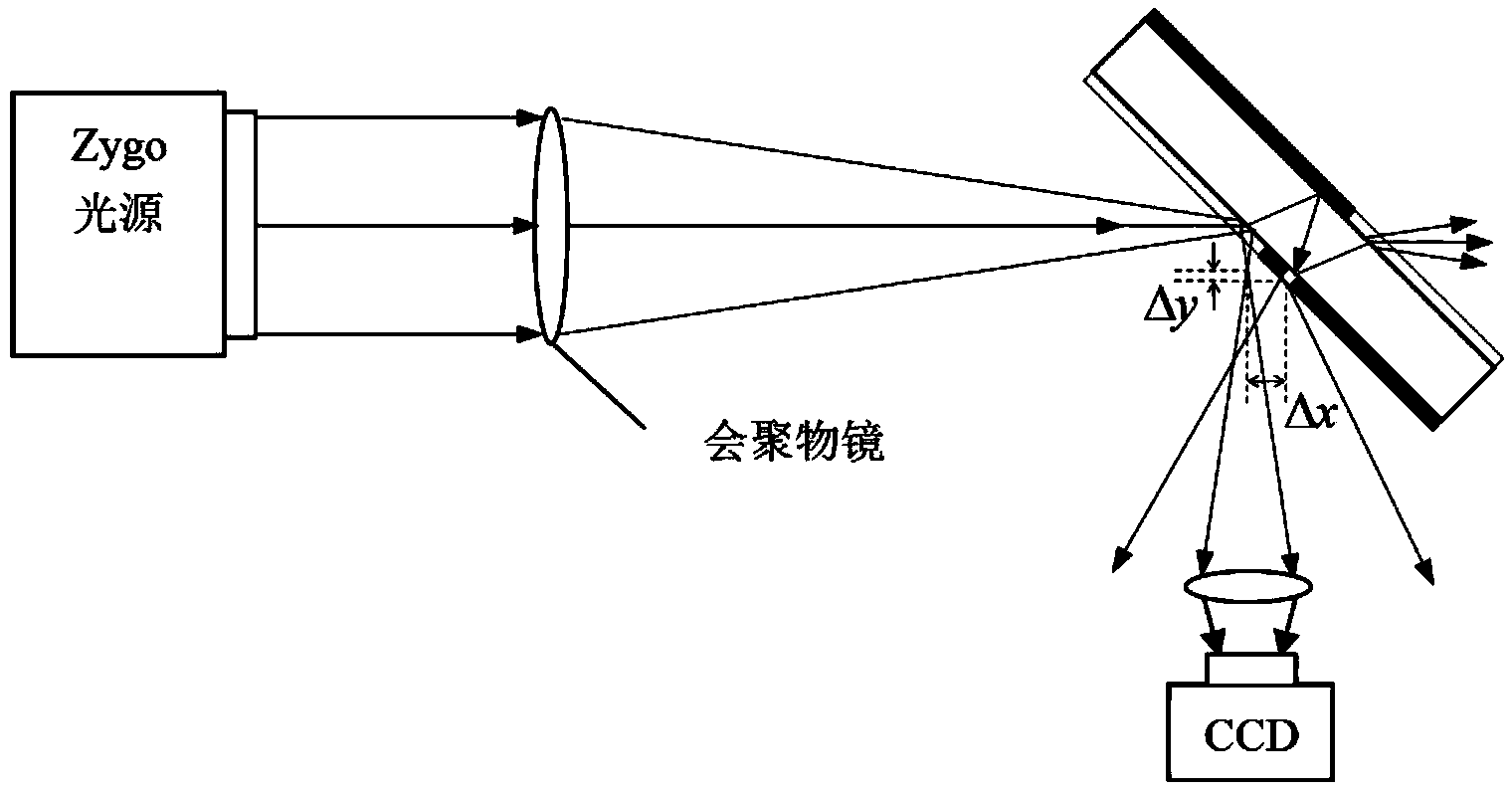

[0049] Step 1: First calibrate the converging objective lens. Each instrument according to figure 2 In the installation shown, the point diffraction plate is placed near the focal plane of the converging beam with an inclination of 45° relative to the optical axis, that is, the angle θ between the optical axis of the converging beam and the normal line of the incident surface of the point diffraction plate is 45°. Adjust the imaging lens so that the detector is conjugate to the exit pupil of the objective lens, use Zygo’s standard parallel light source as the light source, and its wavelength is λ, and then further adjust the position of the point diffraction plate to make the contrast of the interferogram received on the detector better.

[0050] Step 2: Collect the carrier fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com