Cylindrical part surface machining stress measuring method based on finite element compensation coefficient

A compensation coefficient and stress measurement technology, applied in the field of stress measurement and surface machining stress measurement of cylindrical parts based on the finite element compensation coefficient, can solve the problems of complex calculation process, unsatisfactory accuracy requirements and constraints, and achieve simple calculation, Simple method and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

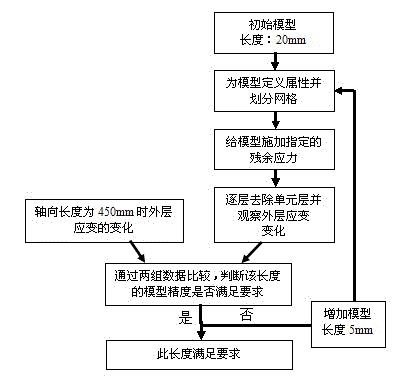

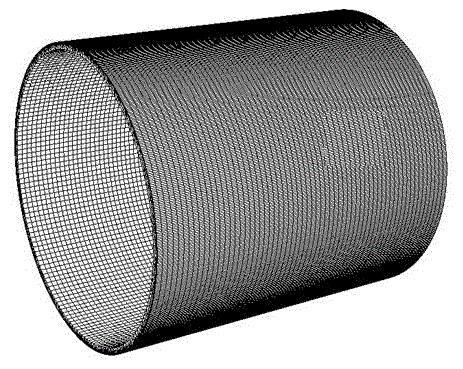

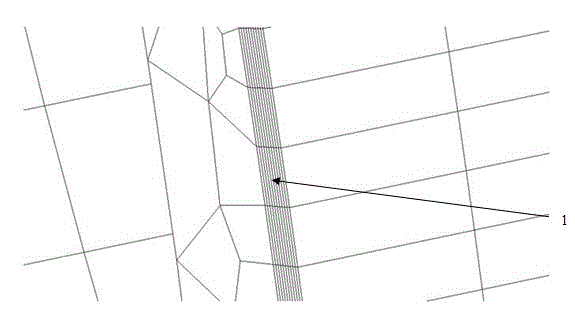

[0033] The model is established in Abaqus software, and the overall figure of the model established according to the finite element analysis results is as follows figure 2 As shown, the outer diameter value is taken as 45mm, and the inner diameter value is taken as 43mm. According to the point of view in the existing literature, when the length of the pipe reaches 6 times of the outer diameter, the accuracy of the final measured data value is already very high. In order to ensure the accuracy, the length of the model is set to 10 times the outer diameter, that is, the model length is 450mm. This model has high precision, but there are many inconveniences and waste of materials in actual experiments. It can be used as a reference here. Basis for post-optimization. Here, the Python language is used to carry out secondary development of Abaqus to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com