Method and device for filling and sealing

A sealing device and gas replacement technology, which is applied in synchronous devices, liquid filling, packaging, etc., can solve problems such as increased cleaning burden, increased energy used, and reduced gas replacement efficiency, so as to improve gas replacement rate and production performance, eliminate the influence of air bubbles, and improve the effect of gas replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

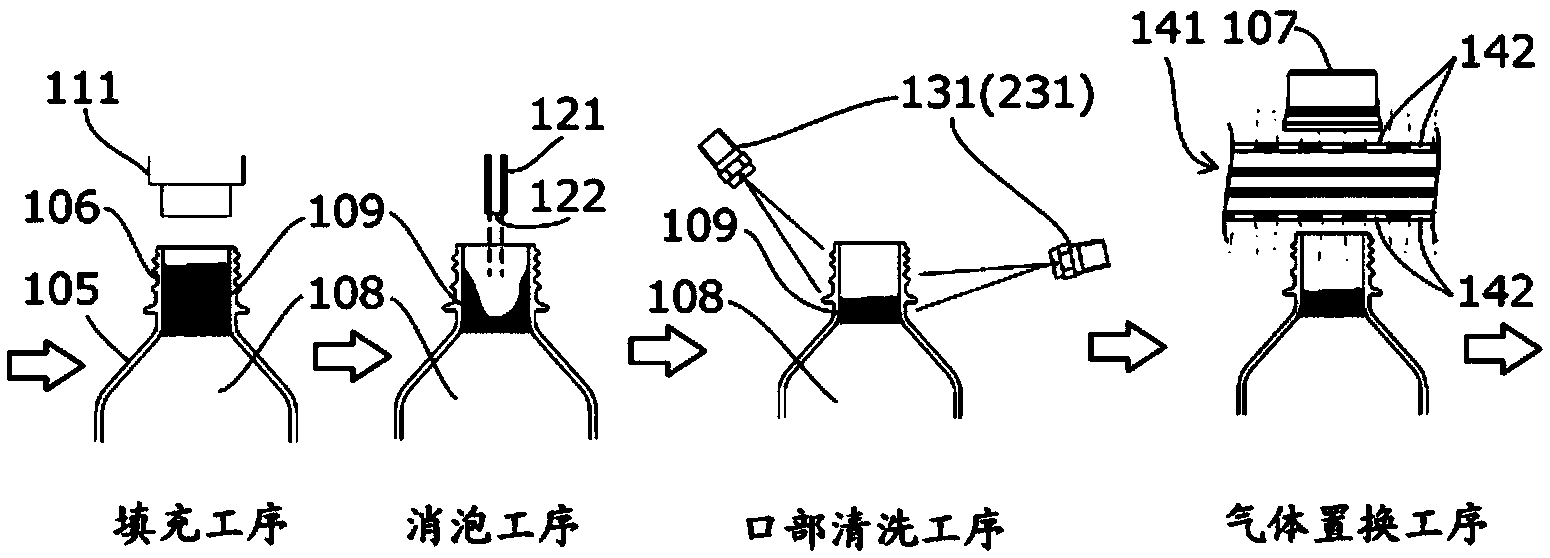

[0063] Hereinafter, the filling and sealing method and apparatus as embodiments of the present invention will be described with reference to the drawings.

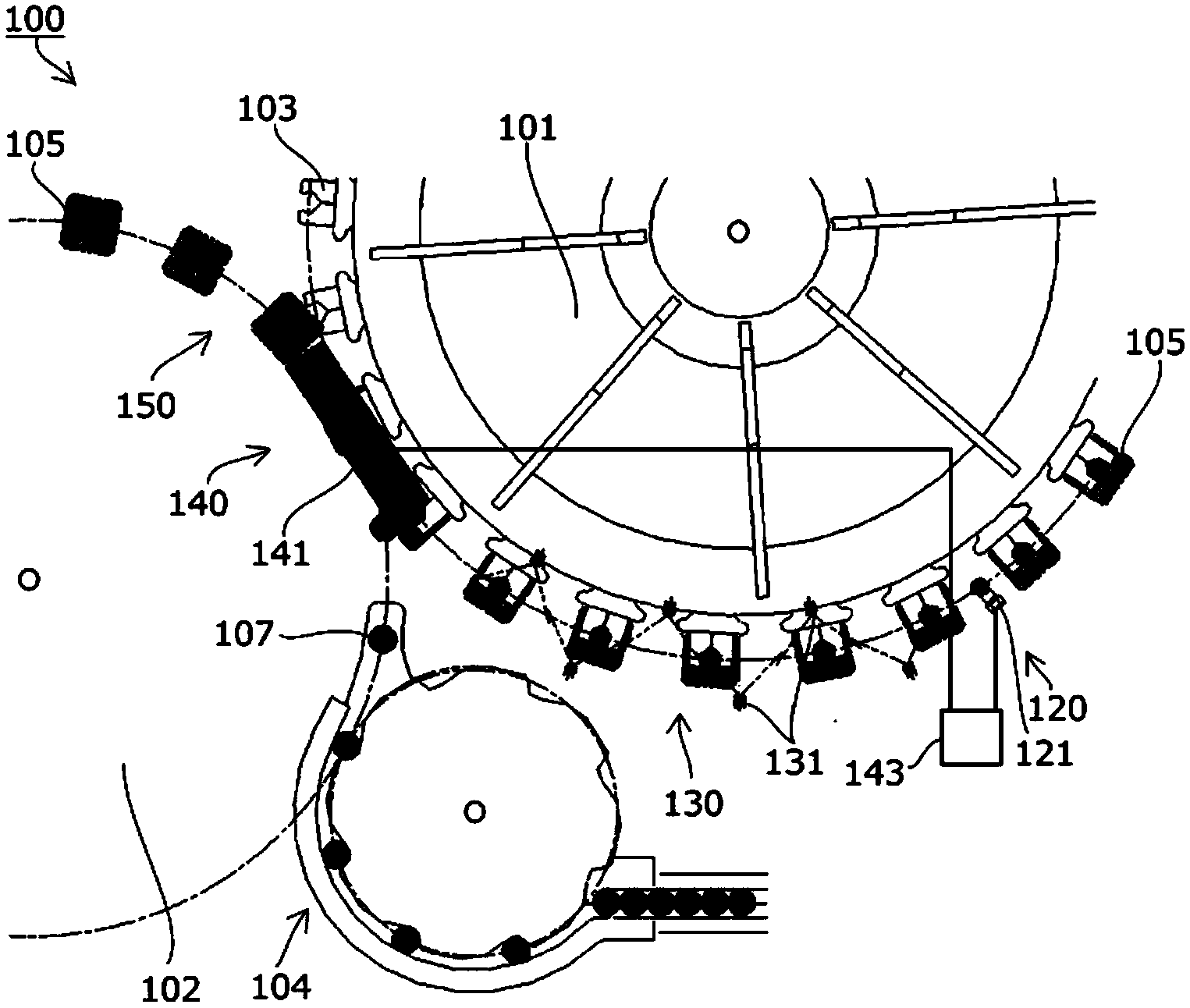

[0064] like figure 1 As shown in the schematic plan view of , the filling and sealing apparatus 100 according to the first embodiment of the present invention includes a first conveying turntable 101 which is provided with holding arms 103 at equal intervals on the outer periphery and continuously rotates, and a second conveying turntable having the same structure. 102 (simplified in the drawing), and it is configured to be able to continuously convey while utilizing a well-known appropriate mechanism to hold the bottle-shaped container 105.

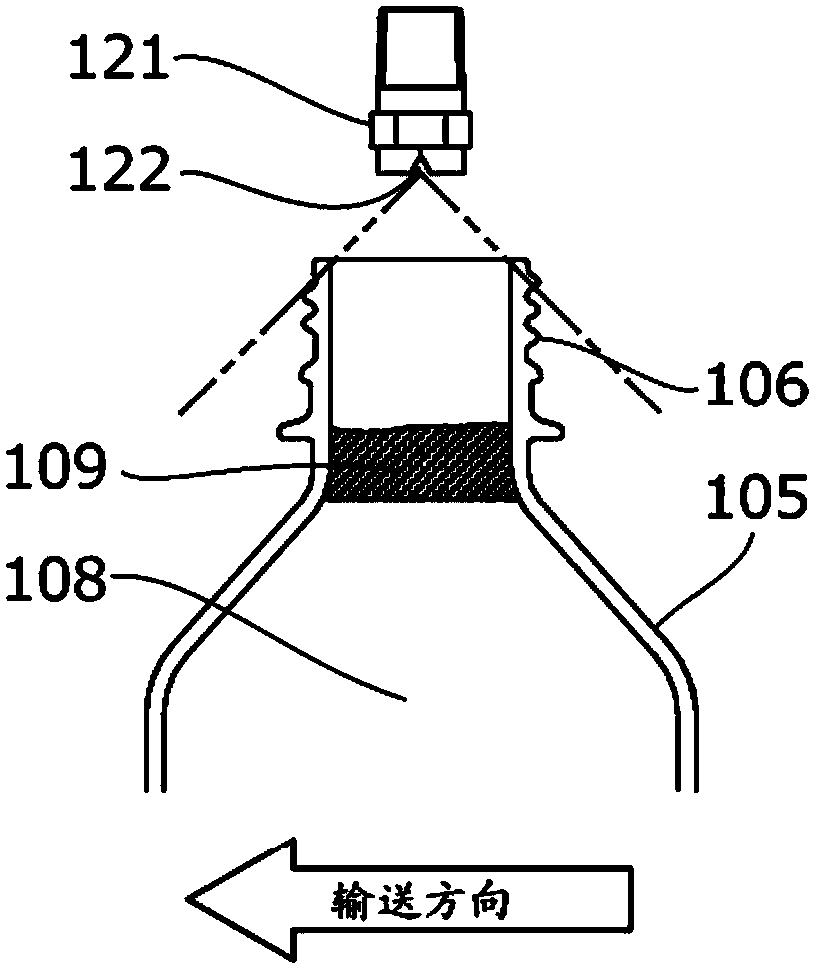

[0065] The filling area (not shown) where the filling process is performed upstream of the first transport turntable 101, the defoaming area 120 that is grasped by the first transport turntable 101 to perform the defoaming process, and the mouth cleaning area that performs the mouth ...

Embodiment approach 2

[0093] Next, a second embodiment of the filling and sealing method and apparatus of the present invention will be described with reference to the drawings.

[0094] The filling and sealing device 200 of the second embodiment of the present invention is as Figure 4 As shown in the schematic top view, the mouth cleaning area 230 where the mouth cleaning process is performed extends to the gas replacement area 140 where the gas replacement process is performed, and the mouth cleaning nozzle 231 is also arranged on the side of the replacement gas injection mechanism 141 .

[0095] The other structures and processes performed in each region are the same as those in the embodiment of the filling and sealing device 100 described above.

[0096] According to the filling and sealing apparatus 200 of this embodiment, even if it is necessary to lengthen the time of the mouth cleaning step in order to clean the air bubbles 109 discharged out of the head space, the production speed can be...

Embodiment approach 3

[0099] Next, a third embodiment of the filling and sealing method and mouth washing process of the device according to the present invention will be described with reference to the drawings.

[0100] like Figure 5 As shown in a brief top view of the figure, the filling and sealing device 300 according to the third embodiment of the present invention is configured such that two mouth washing nozzles 331a from the most upstream among the mouth washing nozzles 331 in the mouth washing area 330 are directed towards the bottle-shaped container 105 Spray cleaning water above the mouth 106 of the container.

[0101] Other configurations and processes performed in each region are the same as those of the filling and sealing device 200 of the second embodiment described above.

[0102] In the mouth washing process of this embodiment, as Image 6 As shown, at least the two mouth cleaning nozzles 331a starting from the most upstream after the defoaming region 120 of the defoaming proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com