Paints with jasmine flower fragrance and preparation method thereof

A jasmine flower and painting technology, which is applied in the direction of art paints and coatings, can solve the problems of low production efficiency of pigments, no fragrance of pigments, not enough health and environmental protection, etc., and achieve the effect of no adverse side effects, strong tinting power and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

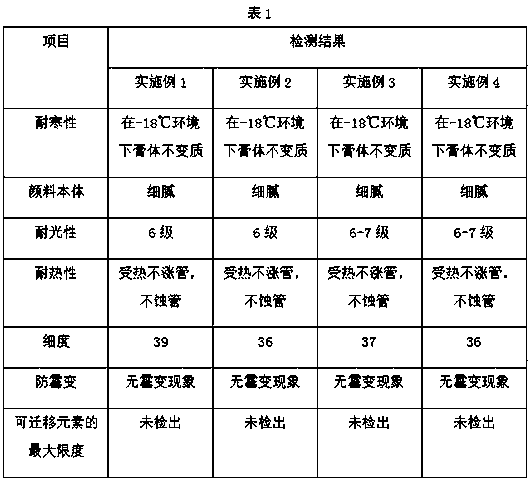

Examples

Embodiment 1

[0037] A paint pigment with jasmine fragrance, comprising the following raw materials in parts by weight:

[0038] 45 parts of mulberry red pigment extract; 65 parts of polyacrylic acid emulsion; 10 parts of jasmine powder; 0.5 parts of dextrin; 30 parts of nanometer calcium carbonate powder; 3 parts of sodium formate; 2 parts of freeze-thaw stabilizer ethylene glycol; 0.4 part of guar gum; 5 parts of sodium tripolyphosphate; Obtained after 700 mesh sieve;

[0039] The extraction method of described mulberry red pigment extract comprises the steps:

[0040] ①Using the mature fruit of mulberry as raw material, remove the moldy and rotten parts and foreign matter, make pulp, add extractant to the pulp and soak for 2 hours, the solid-liquid ratio W / V of pulp and extractant is 1:15, unit g / mL , the extractant is the ethanol solution obtained after mixing equal volume ratios of HCl with a volume concentration of 0.05% and 90% ethanol;

[0041] ②Under the conditions of ultrasonic...

Embodiment 2

[0049] A paint pigment with jasmine fragrance, comprising the following raw materials in parts by weight:

[0050] 50 parts of mulberry red pigment extract; 70 parts of polyacrylic acid emulsion; 15 parts of jasmine powder; 1 part of dextrin; 40 parts of nano calcium carbonate powder; 3 parts of water-based defoamer BEK-750; 5 parts of sodium formate; 4 parts of freeze-thaw stabilizer ethylene glycol; 0.7 part of guar gum; 8 parts of sodium tripolyphosphate; Obtained after 800 mesh sieve;

[0051] The extraction method of described mulberry red pigment extract comprises the steps:

[0052] ①Using the mature fruit of mulberry as raw material, remove the moldy and rotten parts and foreign matter, make pulp, add extractant to the pulp and soak for 3 hours, the solid-liquid ratio W / V of pulp and extractant is 1:15, unit g / mL , the extractant is the ethanol solution obtained after mixing equal volume ratios of HCl with a volume concentration of 0.05% and 90% ethanol;

[0053] ②U...

Embodiment 3

[0061] A paint pigment with jasmine fragrance, comprising the following raw materials in parts by weight:

[0062] 47 parts of mulberry red pigment extract; 68 parts of polyacrylic acid emulsion; 12 parts of jasmine powder; 0.7 parts of dextrin; 35 parts of nano calcium carbonate powder; 2 parts of water-based defoamer BEK-750; 4 parts of sodium formate; 3 parts of freeze-thaw stabilizer ethylene glycol; 0.5 part of guar gum; 6 parts of sodium tripolyphosphate; Obtained after 750 mesh sieve;

[0063] The extraction method of described mulberry red pigment extract comprises the steps:

[0064] ①Using the mature fruit of mulberry as raw material, remove the moldy and rotten parts and foreign matter, make pulp, add extractant to the pulp and soak for 2.5 hours, the solid-liquid ratio W / V of pulp and extractant is 1:15, unit g / mL , the extractant is the ethanol solution obtained after mixing equal volume ratios of 0.05% HCl and 90% ethanol with a volume concentration;

[0065] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com