Post-processing method for carbon-supported Pt-Fe catalyst

A catalyst and carbon-supported technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as complex methods and harsh conditions, achieve simple methods, improve catalytic oxidation, and overcome stability Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) FeCl 3 、H 2 PtCl 6 and VulcanXC-72 are uniformly dispersed in the aqueous solution, and the substances contained in it are prepared according to the mass ratio of Fe:Pt:C=10:10:80 to prepare a mixed suspension, and mix well;

[0045] 2) Place the suspension in 1) in a water bath at 50°C, evaporate the solvent to dryness, and obtain a black powder;

[0046] 3) Put 2) the black powder in H 2 / N 2 (10%H 2 ) in a tube furnace at 500°C for 3 hours to obtain the original PtFe / C catalyst;

[0047]4) soak 3) the original PtFe catalyst in 0.5molL -1 In the sulfuric acid solution, keep at 80°C, and magnetically stir for 24 hours to obtain a black suspension;

[0048] 5) Cool the black suspension described in 4) to room temperature, suction filter, wash, and vacuum-dry at 80° C. for 8 hours to obtain a chemically dealloyed PtFe / C catalyst.

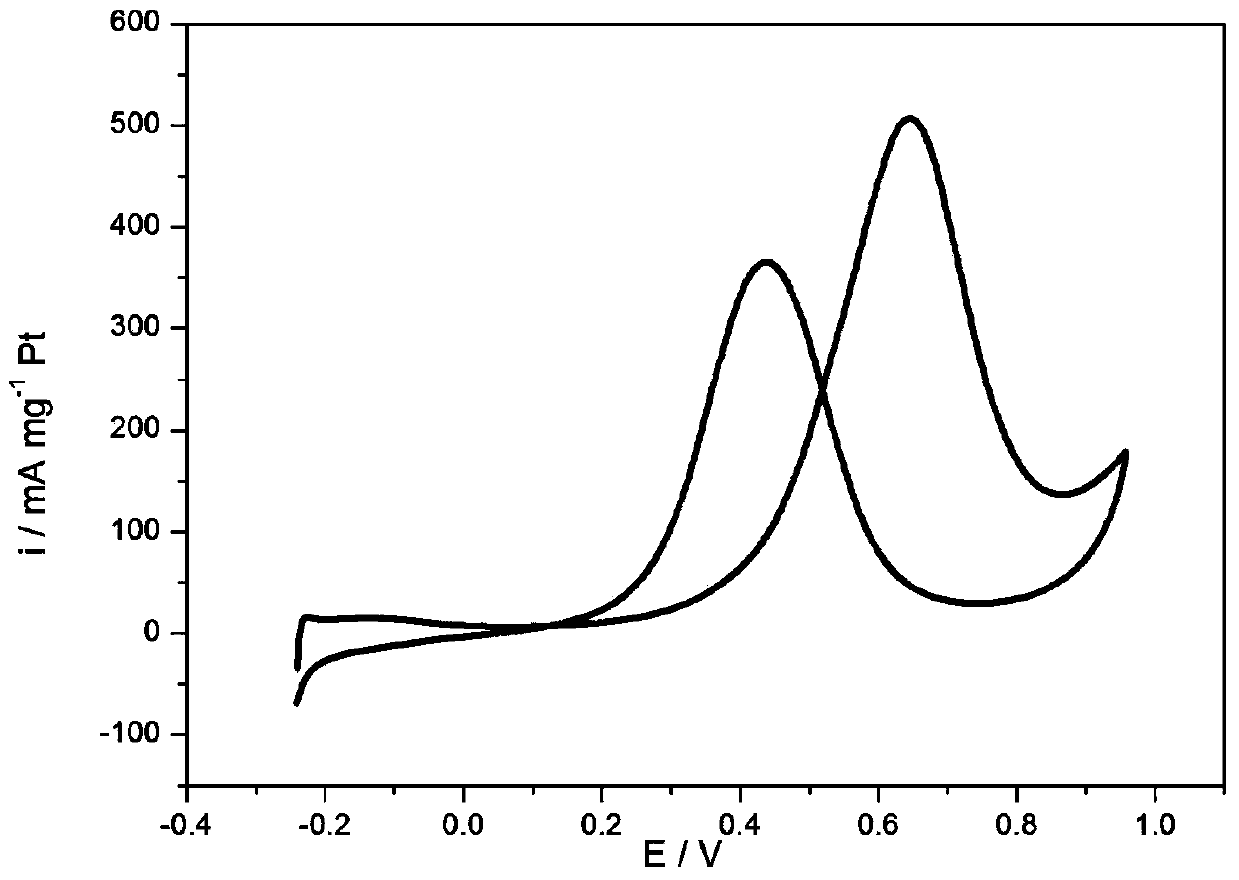

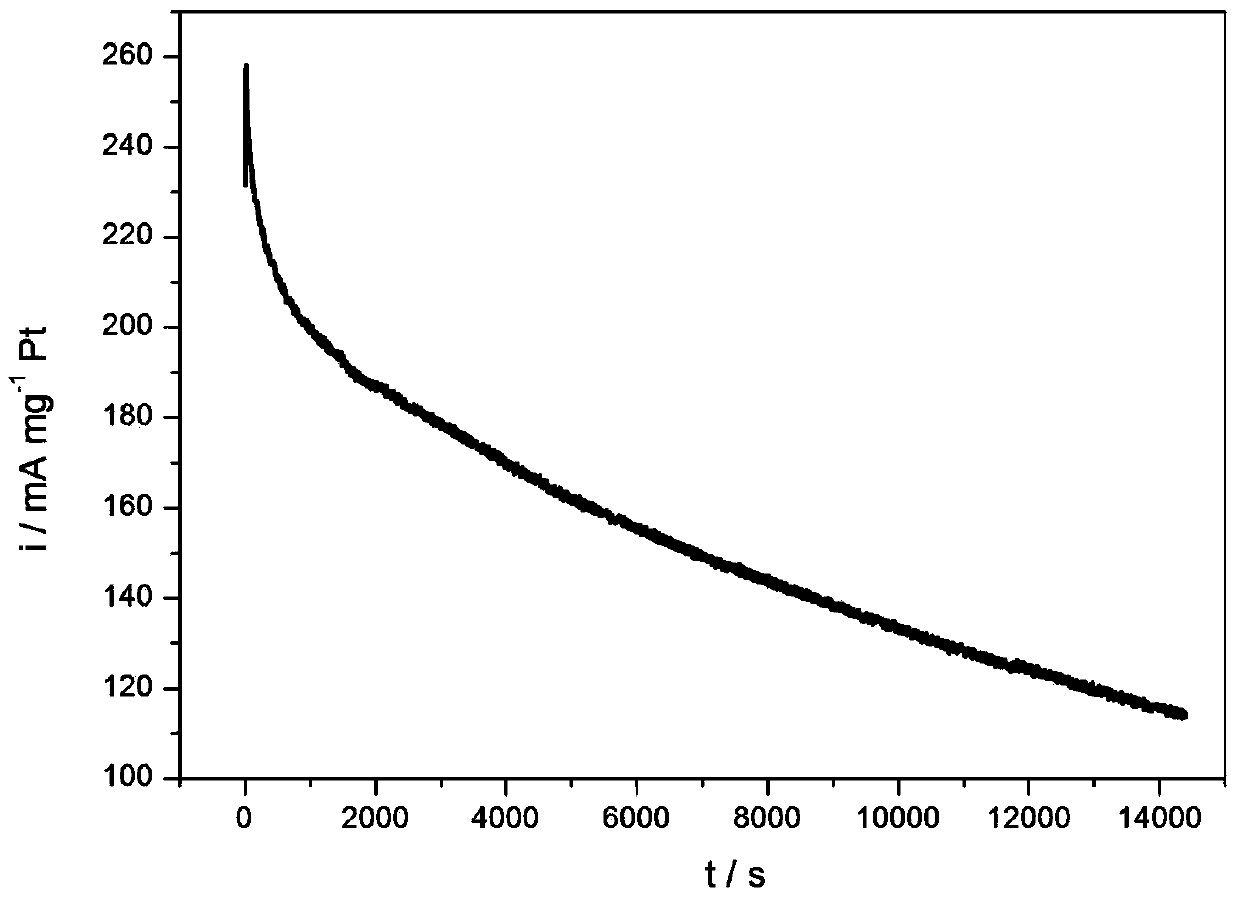

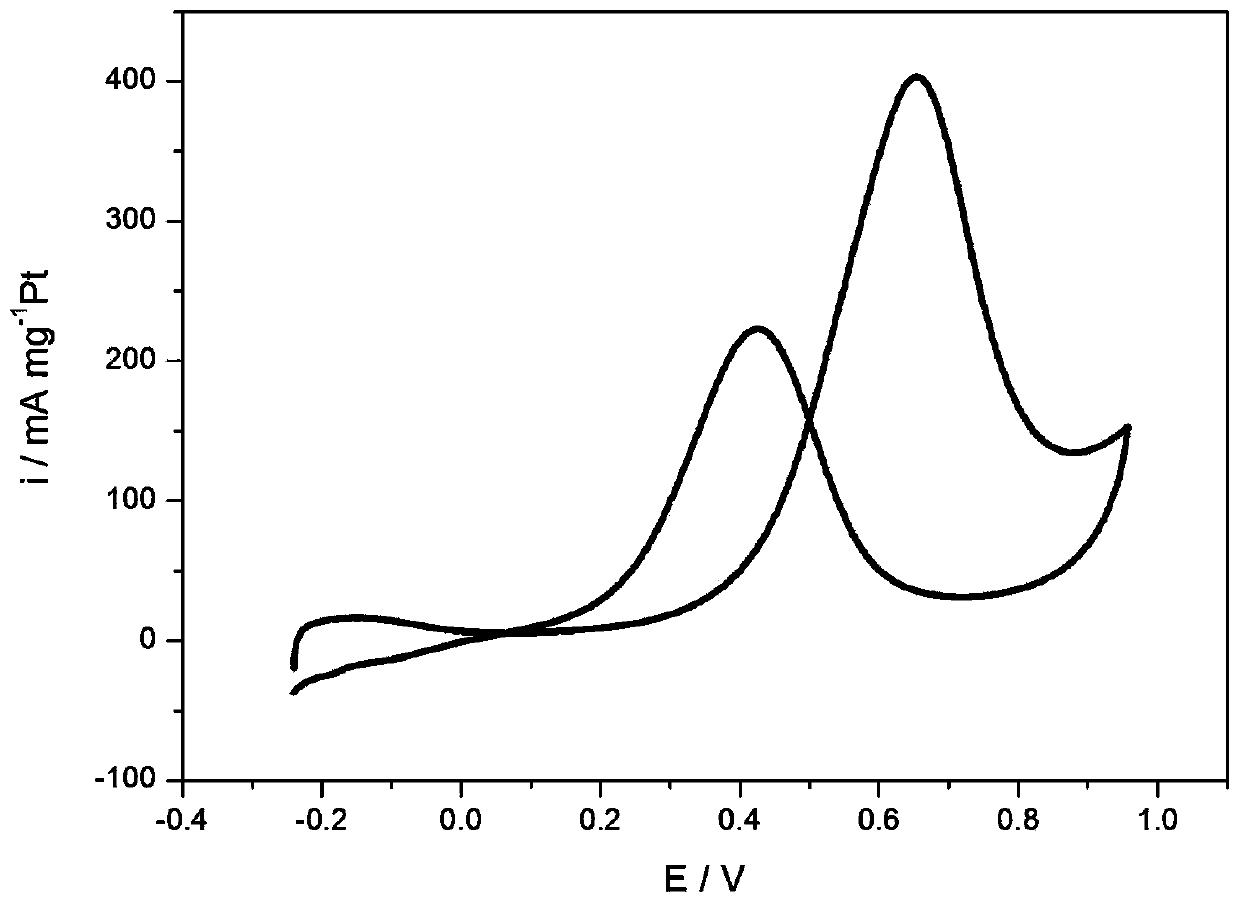

[0049] Add 5 mg of the above-mentioned chemical dealloying PtFe / C catalyst to 50 μL of the Nafion solution produced by Ladrich wit...

Embodiment 2

[0051] 1) FeCl 3 、H 2 PtCl 6 and VulcanXC-72 are uniformly dispersed in the aqueous solution, and the substances contained in it are prepared according to the ratio of mass ratio Fe:Pt:C=13:7:80 to prepare a mixed suspension, and mix well;

[0052] 2) Place the suspension in 1) in a water bath at 50°C, evaporate the solvent to dryness, and obtain a black powder;

[0053] 3) Put 2) the black powder in H 2 / N 2 (10%H 2 ) in a tube furnace at 500°C for 3 hours to obtain the original PtFe / C catalyst;

[0054] 4) soak 3) the original PtFe catalyst in 0.5molL -1 In the sulfuric acid solution, keep at 80°C, and magnetically stir for 24 hours to obtain a black suspension;

[0055] 5) Cool the black suspension described in 4) to room temperature, suction filter, wash, and vacuum-dry at 80° C. for 8 hours to obtain a chemically dealloyed PtFe / C catalyst.

[0056] Add 5 mg of the above-mentioned chemical dealloying PtFe / C catalyst to 50 μL of the Nafion solution produced by Ladri...

Embodiment 3

[0058] 1) FeCl 3 、H 2 PtCl 6 and VulcanXC-72 are evenly dispersed in the aqueous solution, and the substances contained in it are prepared according to the mass ratio of Fe:Pt:C=15:5:80 to prepare a mixed suspension, and mix well;

[0059] 2) Place the suspension in 1) in a water bath at 50°C, evaporate the solvent to dryness, and obtain a black powder;

[0060] 3) Put 2) the black powder in H 2 / N 2 (10%H 2 ) in a tube furnace at 500°C for 3 hours to obtain the original PtFe / C catalyst;

[0061] 4) soak 3) the original PtFe catalyst in 0.5molL -1 In the sulfuric acid solution, keep at 80°C, and magnetically stir for 24 hours to obtain a black suspension;

[0062] 5) Cool the black suspension described in 4) to room temperature, suction filter, wash, and vacuum-dry at 80° C. for 8 hours to obtain a chemically dealloyed PtFe / C catalyst.

[0063] Add 5 mg of the above-mentioned chemical dealloying PtFe / C catalyst to 50 μL of the Nafion solution produced by Ladrich with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com